Catalog excerpts

MflCHENDORFF Automation GmbH & Co. KG Wachendorff Automation GmbH & Co. KG IndustriestraBe 7 • D-65366 Geisenheim Tel.: +49(0) 6722/99 65-25 • Fax: +49(0) 6722/99 65-70 E-Mail: wdg@wachendorff.de • www.wachendorff.de • Exceptionally rugged length sensor • Measuring range: 0 - 1250 mm • Interface: CANopen CiA 406 • free configurable • IP65 absolute encoder WDGA CANopen ready-mounted www.wachendorff-automation.com/szg65wdgacan The draw-wire encoder SZG65 WDGA CANopen was developed for use in harsh environments. The various methods of installation mean high flexibility. It can be used even where space is tight, thanks to its compact dimensions. The SZG65 WDGA CANopen can be mounted quickly and with its highly precise mechanics provides reliable accurate length measurement, with all advantages, which result from an absolute lenght measurement. e. g. The position-value is saved, if supply breaks down and is available immediately if supply gets recovered. Doing a reference run isn't necessary. The intelligent spring-suspension and the nylon-coated stainless-steel wire cable guarantee long-service life, even in difficult operating conditions. The encoder is already installed. Resolution measurement ranges: Position per mm Bit per revolution 2.5 8 Connection configuration for encoder WDGA CANopen: Deviation: Measuring wire: Wire connection: max. wire speed: Pull out strength: System-unit housing: Weight: Less than 0.02 % of the final value. 0.48 mm of thick nylon coated high-grade steel wire. (incl. coating) eye, see drawing 7.5 m/sec. approx. 0.14 kg anodised aluminium/ steel case chrome-plated SZG incl. encoder max. 1 kg Life expectancy: Operating temperature: Storage temperature: at least 10 million cycles -20 °C up to +70 °C -30 °C up to +80 °C Interface Protocol: CAN CANopen - Communication profil CiA 301 - Device Profile for encoder CiA 406 V3.2 class C2 Node number: 0 up to 127 (default 127) Baud rate: 10 kBaud up to 1 MBaud with automatic bit rate detection The standard settings as well as any customization in the software can be changed via LSS (CiA 305) and the SDO protocol, e. g. PDOs, Scaleing, Heartbeat, Node-ID, Baud rate, etc. It is recommend to configure object 6000 h resolution and direction to ccw. All details in mm and dependent on the encoder configuration Programmable CAN transmission modes • Sychronous mode: when a synchronisation telegram (SYNC) is received from another bus node, PDOs are transmitted independently. • Asynchronous mode: a PDO message is triggered by an internal event. (e.g. change of measured valued, internal timer, etc.) Electrical Data: Supply voltage: 10 VDC up to 30 VDC 2012-06-22 / Errors and modifications reserved.

Open the catalog to page 1

Ordering information: Measurement range: 1250 = 1.250 mm Measurement wire: N = 0.48 mm of thick nylon coated high-grade steel wire Mounting direction: UP = Wire exit up DN = Wire exit down FR = Wire exit front BK = Wire exit back Singleturn resolution in bit per revolution ( 1250 mm measurement ranges) 8 => 8 bit (= approx. 2.5 position /mm) 9 => 9 bit (= approx. 5.1 position /mm) 10 => 10 bit (= approx. 10.2 position/mm) 11 => 11 bit (= approx. 20.4 position/mm) 12 => 12 bit (= approx. 40.9 position/mm) Multiturn resolution 18 = 18 bit Interface CO = CANopen Software: A = up to date...

Open the catalog to page 2

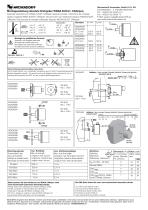

MflCHENDORFF Montageanleitung absolute Drehgeber WDGA EnDra®, CANopen, Assembly instructions for WDGA EnDra®, CANopen absolute encoder, Instructions de montage, capteur angulaire WDGA EnDra®, CANopen, Istruzioni per l'uso trasduttore assoluto WDGA EnDra®, Wachendorff Automation GmbH & Co. KG IndustriestraBe 7 • D-65366 Geisenheim Tel.: +49(0) 6722/99 65-414 Fax: +49(0) 6722/99 65-70 E-Mail: support-wdga@wachendorff.de CANopen, Instrucciones de montaje codificador absoluto WDGA EnDra®, CANopen. Montage nur qualifiziertes Personal Assembly only qualified personnel Montage pair qualifie...

Open the catalog to page 3All Wachendorff Automation GmbH & Co. KG catalogs and technical brochures

-

Wachendorff Panel meters

8 Pages

-

Silent Move Compact

4 Pages

-

Magnetic Encoder WDG 24C

2 Pages

-

WDG 100H

2 Pages

-

WDG 100l

2 Pages

-

Systems and encoders WDG

2 Pages

-

Cranes and construction

4 Pages

-

Quality control

4 Pages

-

Quality testing

4 Pages

-

Elevator

4 Pages

-

Test rig

3 Pages

-

Drink Technology

4 Pages

-

Construction vehicles

4 Pages

-

Food Industry

4 Pages

-

Elevator Construction

4 Pages

-

Metal working

4 Pages

-

Machine building

4 Pages

-

Automated guided vihicle

3 Pages

-

Web-processing industry

4 Pages

-

The HALT-Test

5 Pages

-

Mobile cleaning machines

4 Pages

-

Packaging machines

5 Pages

-

Cranes and Work Platforms

5 Pages

-

Industrial Robots

5 Pages

-

Packaging solutions

5 Pages

-

Marking Systems

3 Pages

-

WDGAK58B-58E

2 Pages

-

cable systems SZG

2 Pages

-

Silent Move light

2 Pages

-

Motorfeedback WDGF

2 Pages

-

position measurement

2 Pages

-

PROFIBUS

2 Pages

-

PROFINET

2 Pages

-

EtherCAT

2 Pages

-

WDGA36A

2 Pages

-

Absolute encoders WDGA

2 Pages

-

Encoders 58 Series

2 Pages

-

WDG24C

2 Pages

-

WDG145H

2 Pages

-

WDG100H

2 Pages

-

WDG100I

2 Pages

-

WDG(I) encoders

2 Pages

-

WDG 58T

5 Pages

-

WDG 53V

7 Pages

-

WDG 50B

9 Pages

-

WDG 40K

11 Pages

-

WDG743XIOM

43 Pages

-

Encoder WDG 30A

7 Pages

-

Encoder accessories

1 Pages

-

WDG 67Q

14 Pages