Catalog excerpts

Technology overview Motors and drives Introducing energy saving opportunities for business

Open the catalog to page 1

Preface Menu Reducing energy use makes perfect business sense; it saves money, enhances corporate reputation and helps everyone in the fight against climate change. We provides simple, effective advice to help organisations take action to reduce carbon emissions, and the easiest way to do this is to use energy more efficiently. This technology overview introduces the main energy saving opportunities for motors and drives. By taking simple actions you can save energy, cut costs and may increase profit margins.

Open the catalog to page 2

Motors and drives in industry Menu Most moving applications and many modern-day devices are powered by electric motors. These range in size from large industrial pumps to small office ventilation fans. Globally electric motors are estimated to account for 40% of all electricity consumption and in industry in the UK they account for almost two thirds of the entire industrial electricity consumption. The cost of buying an electric motor is only the start. In just a single year a running motor can cost up to ten times its purchase cost in energy. Typical running costs for a fully loaded motor...

Open the catalog to page 4

Technology overview Understand motors and be better able to detect wasted energy. Menu An electric motor converts electrical energy into rotating mechanical energy to drive devices such as pumps, fans or conveyors. The mechanical output power delivered by the motor is measured in kW and is a function of the speed (revolutions per minute (rpm)) and torque (the turning force applied). Electric motors are available in standardised sizes and power ratings usually ranging from 100W to several MW. There are different types of motor, each of which has different characteristics, advantages and...

Open the catalog to page 5

Understanding the motor Understanding the components of a motor and how it works shows how energy wastage can occur within it. Menu Figure 1 shows the parts that make up an induction motor, from the terminal box where the electrical input is connected either directly from the mains/grid supply or from a VSD, to the output shaft driving the load. Figure 1 Cutaway view of an AC induction motor Eyebolt Rotor (2) Frame Rotor laminations Bearing (4) Wound stator (1) Shaft (3) Terminal box Drain hole In summary, as electrical power is applied, a rotating magnetic field is created around the...

Open the catalog to page 6

Variable speed drives (VSDs) Whilst there are a number of variations in VSD design; they all offer the same basic functionality. They convert the incoming electrical supply of fixed frequency and voltage into a variable frequency and variable voltage feed to the motor with a corresponding change in the motor speed and torque. The motor speed can be varied from zero through to typically 120% of its full rated speed. Up to 150% rated torque can be achieved at reduced speed. Most VSDs offer computing intelligence and are able to be connected to a variety of control systems and sensors. Using a...

Open the catalog to page 7

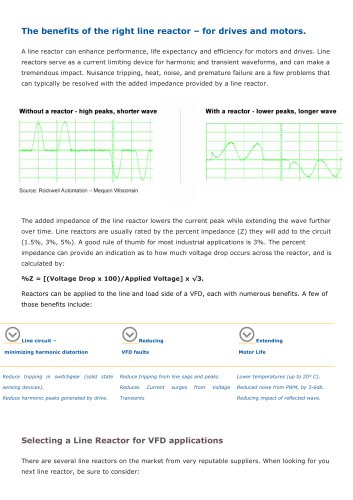

Figure 4 Typical system losses cubed. In essence, this means that any speed reduction will save large amounts of energy, for instance a 20% speed reduction will result in up to approximately a 50% power saving. Driven equipment (d) 78.7% 57% useful energy Electricity input Transfer system losses 10% In the example, the drive unit (a) requires electricity to power the electronics; some of this is lost as heat in the drive unit (typically 5%). The motor (b) has various internal losses, and if it is attached to a transmission system (c) for example, a gearbox or pulley, then this introduces...

Open the catalog to page 8

Opportunities for energy saving in motor systems Menu Simple actions lead to significant savings. Switch-off policy and stop-start Control Because motors are so common and often ‘hidden’ within machinery they tend to be ignored and left running even when they are doing no useful work. For example watch what happens to motor-powered equipment when there is no production during a tea break or job change. Is it left running when not required? Other examples include circulating water in heating or cooling systems when there is no demand, or ventilating unoccupied spaces. Once equipment has been...

Open the catalog to page 9

Minimising demand and process optimising Minimising the demand placed on a system, or optimising the process can lead to significant energy savings. Careful analysis of the process requirements will identify opportunities to reduce the demand; these could vary from reducing the throughput to reducing operating set points such as temperature or pressure settings. A system can be designed to match the demand, such as the throughput rates matching the process requirements. See System design and optimisation section. It may be possible to change the system or process that a motor is driving to...

Open the catalog to page 10

Examples of optimising systems include selecting pumps or fans that are better suited to the duty requirements, or sizing pipe work or ducts to minimise flow velocities and associated friction losses, or changing pulley ratios on fans to better match their speed with the airflow requirement. Figure 5 illustrates the intersection of a pump characteristic curve with a system performance curve at different flow rates. The efficiency at operating point 1 exceeds the efficiency at operating point 2. Figure 5 Select components to ensure the system operates at its Best Efficiency Point (1) Pump...

Open the catalog to page 11

VSDs are particularly beneficial in variable torque load applications such as fans and pumps where the output is controlled by other means such as inlet or outlet throttling, or damper adjustment. For example, savings of up to 50% of energy use are achievable by reducing the fan or pump motor speed by 20%. Figure 6 VTdrive 0.75kw 400V Variable speed drive Integrated motor – drive units are able to interface with transducers and analyse and react to different load conditions without needing to feedback information to a central control system. This can result in a faster response time and...

Open the catalog to page 12All VTDRIVssE Technology Limited catalogs and technical brochures

-

Brake unit FWI-BU3 series

1 Pages

-

VS5 Solar pump inverter

3 Pages

-

VTdrive What is a Choke Coil

2 Pages