Website:

voxeljet

Website:

voxeljet

Catalog excerpts

weight · sametimes stiffer · 3 - 5 for mass production · capable WHITEPAPER 3D Printing for Innovative Mould Making Combined with Simulation Driven Design Inspiration Push the Limits for High Performance Castings Altair, Click2Cast, HBM nCode, and voxeljet present a technology demonstration that stands out with dramatic performance improvements and the solid potential for serial manufacturing and mass production. Bringing design optimization, fatigue analysis, casting, and 3D printing together addresses the challenges of lightweight design and enables the creation of an innovative design and manufacturing process that enhances performance and efficiency. „When it comes to speed and capabilities for serial production you might want to look at this process. It marks the “rebirth” of one of the oldest manufacturing process available – casting! The new process includes moulds made with 3D printing, an entirely new approach to mould making. By using the voxeljet 3D printing process, mould making is dramatically faster and the design freedom this process offers is great. 3D printing the patterns and moulds, is potentially the only way we can achieve this level of cast complexity. To leverage the design freedom 3D printing offers to full capacity, the design for the printed piece comes from simulation tools, which provide structural inspiration and enable the assessment of manufacturability and durability. The result we have received is very promising: the component is now 3-5 times stiffer (depending on the load case) than the original design without having to add weight. Another great advantage of this approach is, that the manufacturing process is already well established, certified in various industries and is suitable for mass production.“ Tobias King, Director Marketing & Applications, voxeljet AG THE TECHNOLOGY DEMONSTRATOR Using a milled billet aluminum upright (wheel carrier) to demonstrate the process, designers and engineers from the companies focused on creating a new shape for the wheel carrier that would be equal in mass but would perform significantly better than the original. The wheel carrying component is subject to deflections and deformations under load, which significantly impact the road-holding performance of the entire suspension. Stiffness of the component is critical. The original design, driven more by manufacturing needs, was now reworked for

Open the catalog to page 1

TOPOLOGY OPTIMIZATION WITH INSPIRE Topology optimization process with solidThinking Inspire First, the design space was defined using Inspire, a concept design and optimization tool based on Altair’s OptiStruct optimization solver. Then the most severe load cases, such as hard braking, maximum cornering, and driving over bumps, were applied to the model. After running the optimization, which also took manufacturability into account, the result was a part with exactly the same amount of material (now aluminum cast) but distributed in such a way as to increase stiffness by a factor of 3-5,...

Open the catalog to page 2All Voxeljet catalogs and technical brochures

-

High Speed Sintering

2 Pages

-

Inorganic-Direct-Binding

2 Pages

-

machine-data-sheet-vx4000

1 Pages

-

machine-data-sheet-vx200

1 Pages

-

voxeljet 3D printer

1 Pages

-

VX200 HSS

2 Pages

-

Servicebrochure_2018

6 Pages

-

plastic parts

1 Pages

-

Imagebrochure

20 Pages

-

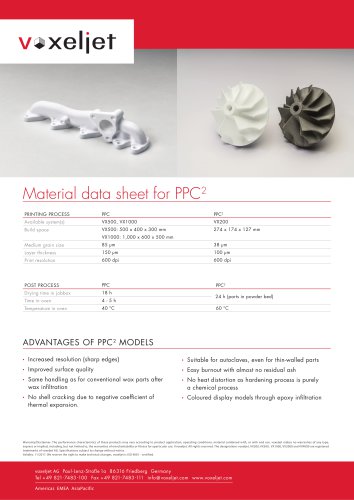

Material data sheet for PPC²

2 Pages

-

Investment casting

1 Pages

-

technical-data-3d-printer

1 Pages

-

Material-data-sheet

1 Pages

Archived catalogs

-

VX4000

1 Pages

-

VX2000

1 Pages

-

VX500

1 Pages

-

VX200

1 Pages

-

Servicebroschure

6 Pages