Website:

Volvo Construction Equipment

Website:

Volvo Construction Equipment

Group: Volvo

Catalog excerpts

PL3005D, PL4809D Volvo Pipelayers Tipping capacity PL3005D: 51 t / 112,000 lb | PL4809D: 90/102 t / 197,000/225,000 lb

Open the catalog to page 1

! Take advantage of ultimate lift and positioning performance 02S2P with Volvo’s 360° swing capability. The excavator-based design enables the upper structure to swing 360° - providing yout with infinite pipe placement possibilities.

Open the catalog to page 2

New levels of maneuverability Volvo’s revolutionary excavator-based rotating pipelayers deliver a competitive edge in the most demanding conditions. Featuring 360° swing capability for unlimited pipe placement options, you’ll discover more opportunities with Volvo. Mode switch The PL3005D is easily transported without disassembling components – simplifying road transportation. Use split pump flow for better load controllability during simultaneous travel/lifting operations and combined pump flow for maximum performance speed when traveling or in stationary pipe laying operations. The Fine...

Open the catalog to page 3

Lifting your productivity Get a grip on your workload with Volvo’s pipelayers. Featuring best-in-class lifting capacity and stability, you can trust Volvo to help you get the job done quickly, efficiently and safely. Boom extension Working range Volvo pipelayers feature long booms which, together with the boom mounting position, provide a higher hook height and reach – allowing the machines to easily lift and lower pipes from a safe distance. If more reach is needed, pre-prepared booms allow for quick and easy installation of an optional boom extension. This provides the same lifting...

Open the catalog to page 4

Best in class Superior lifting capacity and stability make Volvo’s pipelayers the most productive and safe machines for the job. With a 51 ton tipping capacity, the PL3005D handles large, heavy pipe with ease. *90 ton tipping capacity for the PL4809D.

Open the catalog to page 5

LMS The Load Management System allows operators to see what they can safely pick up relative to the slope. By monitoring slope inclinations as well as boom angle and orientation, the operator can easily manage the load at all times.

Open the catalog to page 6

Unrivalled safety Safety is at the forefront of Volvo’s pipelayer design. The unique Load Management System (LMS) is just one of the buitlt-in safety features that will help to increase your performance and productivity. A Volvo pipelayer won’t let you down. The operator receives machine load information, via wireless sensors, to the cab monitor. Visible and audible warning signals alert the operator when the load limit is reached. For increased safety, three different color (green, yellow and red) LEDlights on either side of the boom indicate the pipelayer’s load status to other operators...

Open the catalog to page 7

Get productive in comfort Volvo understands the importance of operator comfort. That’s why we’ve carefully designed an industry leading, raised cab with built in comfort and excellent all-round visibility. Operators will feel in control and perform efficiently all day long in this superior working environment. Winch control Volvo’s operator friendly design allows you to choose your preferred joystick to operate the winch – simply select left or right via a pattern change control valve. In the elevated position, the unique four-bar cab riser system gives the operator excellent visibility...

Open the catalog to page 8

Volvo cab Dedicated pipelayer cab with enhanced visibility from large expanses of glass and slim cab pillars. The spacious environment provides an adjustable seat, industry-leading automatic climate control system, ample leg room and storage.

Open the catalog to page 9

Reversed cylinder The reverse mounted cylinder and optimized cylinder diameter and length greatly improve lateral visibility. Working range Volvo pipelayers feature long booms which, together with the boom mounting position, provide a higher hook height and reach. Anti two-block device For increased safety and machine uptime, the anti two-block system prevents the winch blocks from coming into contact during lifting. Commonality Commonality between pipelayer and excavator wear and maintenance parts ensures there is high availability of spare parts. LMS Utilizing wireless sensors the Load...

Open the catalog to page 10

Pipelayer supremacy Winch Volvo’s operator friendly design allows you to choose your preferred joystick to operate the winch. 360° 360° swing The superstructure can swing 360° providing you with infinite pipe placement possibilities. Four bar cab riser When elevated, the unique four bar cab riser system provides excellent visibility to the worksite and into the trench. Serviceability Grouped filters and service points are quick to access at ground level via large, wide compartment doors. Slew lock A heavy-duty, mechanical slew lock secures the superstructure at any angle to the...

Open the catalog to page 11

Easy conversion The pipelayer’s hydraulic system is designed to be optimized for both pipelayer and excavator operations. Easily convert your machine with digging equipment (available as an option) for excellent digging power and performance equal to a standard excavator.

Open the catalog to page 12

Extreme versatility Volvo’s excavator-based rotating pipelayers are designed to help you get the most out of your investment. The versatile machines can easily be converted to a standard excavator or used in other heavy lift applications, ensuring maximum machine uptime. Do more with Volvo. Fast conversion Two people can quickly convert the pipelayer to an excavator in just one day thanks to factory pre-installed hydraulic lines and connections. AMS The Attachment Management System (AMS) stores up to 18 attachment pre-sets and permits hydraulic flow (standard) and pressure (optional) to be...

Open the catalog to page 13

Maximizing your uptime On site, time means money. That’s why Volvo pipelayers boast easy access to grouped service points for fast and effortless maintenance and service checks. Commonality between genuine Volvo wear and maintenance parts ensures high availability, ensuring maximum machine uptime. Remote filters The filters are separate from the engine and radiator for easier cleaning and servicing – giving you more machine uptime. Independent coolers provide excellent cooling. Genuine Volvo Parts For the highest levels of quality, use only Genuine Volvo Parts. High availability and low...

Open the catalog to page 14All Volvo Construction Equipment catalogs and technical brochures

-

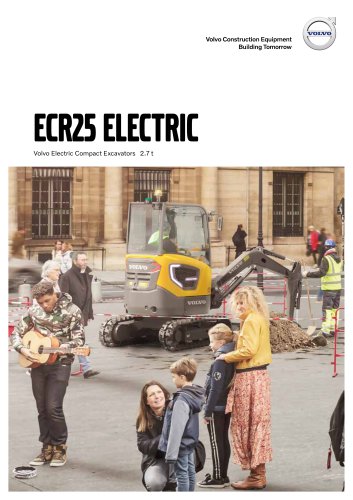

the ECR25 Electric brochure

12 Pages

-

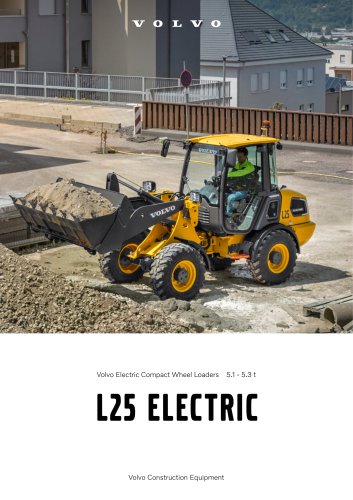

the L25 Electric brochure

20 Pages

-

ECR58

16 Pages

-

ECR58D

20 Pages

-

EW60E

20 Pages

-

ECR88D

24 Pages

-

P6820D ABG, P7820D ABG

16 Pages

-

P7820c ABG, P8820c ABG

16 Pages

-

EC950E

24 Pages

-

ECR18E

8 Pages

-

ECR355E

36 Pages

-

EWR150E, EWR170E

32 Pages

-

EW180E, EW220E

32 Pages

-

EW240E

20 Pages

-

EC27D

12 Pages

-

A25G

20 Pages

-

MC60C

24 Pages

-

MCT110C

24 Pages

-

hydraulic breakers

8 Pages

-

DD25B

8 Pages

-

DD105

20 Pages

-

L250H

24 Pages

-

L180H High-Lift

24 Pages

-

L150H, L180H, L220H

28 Pages

-

L60H, L70H, L90H

32 Pages

-

L45G, L50G

28 Pages

-

L30G, L35G

20 Pages

-

DD31HF-DD38HF

4 Pages

-

DD85-DD95

2 Pages

-

SD25, SD45

4 Pages

-

SD75, SD115, SD135

12 Pages

-

SD160-SD200

4 Pages

-

L30B

6 Pages

-

L30B 1000 Pro

12 Pages

-

L32B

6 Pages

-

L30B to L45B, waste handling

4 Pages

-

L35B Z

8 Pages

-

MC60?MC110

12 Pages

-

MC60B?MC110B

16 Pages

-

L110H, L120H

28 Pages

-

L110G, L120G

32 Pages

-

l60g, L70G, L90G

32 Pages

-

L40B, L45B

6 Pages

-

L30B Pro, L35B Pro

8 Pages

-

L20F, L25F

16 Pages

-

Motor graders G970

10 Pages

-

Dumper A30F

24 Pages

-

Mini Excavator EC15C

16 Pages

-

Backhoe Loader BL61B, BL71B

24 Pages

Archived catalogs

-

G900 Series

6 Pages

-

Compact excavators

8 Pages

-

L60F-L350F

6 Pages

-

Compact wheel loaders

8 Pages