Catalog excerpts

Your Pit Stop for Quality Measure, Inspect, and Simulate—with Volume Graphics Software

Open the catalog to page 1

Get Full Control from Lab to Fab With Volume Graphics Software Just as every millisecond in a pit stop counts in a race, every little detail counts when inspecting safety-relevant components. Volume Graphics is your pit crew. From powder to printed part, from lab to fab—Volume Graphics software gives you the insights to constantly push the quality boundaries of your additively manufactured parts and establish efficient workflows. The software runs on data provided by the latest CT technology. Volume Graphics software enables you to identify the most important 3D printing defects, whether...

Open the catalog to page 2

Scan for more information: Recognized Market Leader Frost & Sullivan, a leading market research and consulting firm, recognized Volume Graphics in an independent benchmark analysis as market leader in the CT software sector with a market share of about 80 percent in 2017. For its “strong overall performance,” “its singular contributions toward consistently advancing the CT systems market,” and a “thorough understanding of end users’ needs,” Volume Graphics has earned Frost & Sullivan’s 2018 Market Leadership Award.* * ource: Frost & Sullivan S Award Write Up volumegraphics

Open the catalog to page 3

Your Comprehensive Toolbox Measure, Inspect, and Simulate—All with One Software VGSTUDIO MAX is your tool for identifying the most important 3D printing defects—from raw material to the post-processed end product. Perform powder and meltpool data analyses, take dimensional measurements of all surfaces—even if they are inside your additively manufactured part—and find defects of all shapes and sizes. Powder Analysis Powder is the base for many additively manufactured parts. The size and shape distribution of new and recycled powder particles influences the build process: it affects how...

Open the catalog to page 4

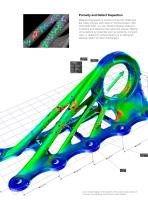

Porosity and Defect Inspection Metal printing based on powder comes with challenges like voids, porosity, and cracks in the final product. With VGSTUDIO MAX, you can identify individual voids and inclusions and determine their sizes and shapes. Filtering of the defects by properties such as sphericity, compactness, or distance to surface allows you to distinguish between defect formation mechanisms. Color-coded display of the locations of the weak points directly on the scan of an additively manufactured cabin bracket

Open the catalog to page 5

Structural Mechanics Simulation VGSTUDIO MAX enables you to perform structural mechanics simulation (SMS) directly on CT scans. Loads and constraints are applied to the CT scanned model, not just the CAD file. Stress concentrations due to geometrical flaws and pores can be simulated and visualized without volume meshing. Volume Meshing For simulation in third-party software, high-quality tetrahedral volume meshes representing the actual geometries and internal defects of the printed parts can be generated. Without intermediate surface meshing, this will avoid the loss of geometry...

Open the catalog to page 6

Volume Graphics Advantages Instructive Results and the Ability to Establish Efficient Work Flows for All Your Tasks Comprehensive >> Comprehensive scope of functionalities for metro logy and defect detection in one software >> Measurement of inner and outer geometries and defects >> Microstructure analysis for both powders (grain sizes, defects) and printed components (printing layers, unmolten material, defects) Instructive >> User-defined filtering of relevant defects, e.g., by size or shape, to distinguish between defect formation mechanisms >> Calculation of defect size relative to...

Open the catalog to page 7

GRAPHICSEnabling better products Charlotte, NC f Bejing $ f Nagoya Singapore f Volume Graphics GmbH has subsidiaries in the US, Japan, China, and Singapore. To broaden our global footprint even more, we can rely on a worldwide network of distributors. Headquarters Volume Graphics GmbH Speyerer StraBe 4 - 6 69115 Heidelberg, Germany Phone: +49 6221 73920-60 Fax: +49 6221 73920-88 sales@volumegraphics.com www.volumegraphics.com © 2019 Volume Graphics GmbH, VGL is a registered trademark of Volume Graphics GmbH, Germany. All company, product, or service names mentioned in this brochure are used...

Open the catalog to page 8All Volume Graphics GmbH catalogs and technical brochures

-

New in VGSTUDIO MAX 3.4

12 Pages

-

VGSTUDIO MAX

34 Pages

-

VG Academy Training Courses

2 Pages

-

VGinLINE

8 Pages

-

VGSTUDIO

6 Pages

-

VGMETROLOGY

8 Pages