Catalog excerpts

WATER FREE ISO CERTIFIED Filter out water and oil www vmeca com . Air-dryer substitute . Extended pneumatic products lifetime . Failure reduction of pneumatic products . Reduction of maintenance time and cost for pneumatic products . Improvement in quality www.vmeca.

Open the catalog to page 1

WATER FREE Compressed air sanctification required ¡ Contaminant in compressed air Solidified Particles Abrasion particles, rusts, or minute sand can flow in to damage pneumatic products. Bulk dense water It leads to freezing, abrasion, or rust to shorten the pneumatic products lifetime. Acidified oil Acidified oil aerosols are mixed with coalesced water and become acid. Liquid oil It contaminates the pipe’s work to lower whole system efficiency. Micro-organism It can lead to an unhealthy working environment with potential for personal injury. ¡ Compressed air problems Atmosphere dust vapor...

Open the catalog to page 2

WATER FREE Main cause of malfunction for pneumatic components ¡ Valve or actuator malfunction due to coalesced grease ¡ Rust of spool valve ¡ Imbibitions of inner gasket ¡ Rust of valve parts ¦ For reference : Exact capacity & coalesced amount depend on compressor maker. ¡ Coalesced water ¡ Solidified powder • adhere ¡ Pipe scale & Rust problems Pipe scale at Auto Drain Air leakage due to broken gasket pipe scale Valve malfunction due to pipe scale Specifications subject to change without notice www.vmeca.com

Open the catalog to page 3

WATER FREE ¡WHAT IS WATER FREE? Compressed air is a safe and reliable power source that is widely used throughout the industry. In proportion to its wide utilization, problems caused by coalesced liquid in compressed air are increasing rapidly. Therefore, WF (Water-Free) is employed to remove moisture in compressed air to enhance its reliability. Compressed air is inserted (flow) into ‡@ Cover expanding rapidly through the ‡A DIFFUSER to become unstable by colliding with ‡B MASH HOUSING separating it into water and moisture. Separated water collected at ‡C MASH FILTER falls into the ‡E AUTO...

Open the catalog to page 4

WATER FREE ¡WATER FREE Installation WATER FREE Installation and Application Pipe/Air Hose (>=15m) Compressor Compressed Air Moisture VMECA WATER FREE Dried Air . Assemble the Water-Free vertically for optimum performance . Pipe /Air hose should be over 15 meters . Installation should be made closest to the vacuum pump possible . If F.R.L. unit is used, Water-Free should be installed right before the F.R.L. Unit • Electrical and electronics industries • Semiconductor line • Pharmaceutical produce line • Food processing line • Cosmetic factory • Chemical facilities • Car assembling line •...

Open the catalog to page 5

Connect port Auto Drain L - type Bracket • 38 - G3/8" • A - Auto Drain Attached • B - Bracket Attached 12 - G1/2" No Mark - Non-attached No Mark - Non Attached 34 - G3/4" WATER FREE Features and Advantages of WATER FREE ¡ Features of Water free ¡ Water free Advantages . Moisture removal up to 99% . No maintenance . Minimal pressure loss . Affected by using time, flow rate, and moisture proportion . No electricity and simple dynamics design . Air]dryer substitute . Extended pneumatic products lifetime . Failure reduction of pneumatic products . Reduction of maintenance time and cost for...

Open the catalog to page 6

¡WATER FREE Application £Veneer sheet transfer line in wooden industry £ Cylinder and pump protection for injection molding line auto-ejector www.vmeca.com Specifications subject to change without notice £Vacuum pump and pneumatic actuator of packaging machine £Vacuum conveyor for dried materials £Protection of pneumatic actuator in factory automation line Distributor (1003008i)

Open the catalog to page 8All VMECA catalogs and technical brochures

-

VBF Series

4 Pages

-

Mini Cartridge Catalog

4 Pages

-

Micro Cartridge Catalog

1 Pages

-

VMECA Mega Pm Pump

5 Pages

-

VMECA Micro Cartridge Pump

6 Pages

-

VMECA Mega Pump

4 Pages

-

Maxflex Pump ( L series)

6 Pages

-

VMECA Conveying Pump

4 Pages

-

VMECA V-Pump (VLS series)

5 Pages

-

VMECA V-Pump (VS series)

5 Pages

-

VMECA MD Pump (MDL series)

5 Pages

-

VMECA MD Pump (MD series)

5 Pages

-

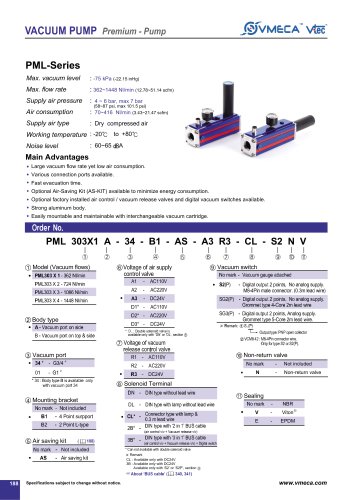

VMECA PM Pump (PML series)

6 Pages

-

VMECA PM Pump (PM series)

6 Pages

-

VMECA Mini-Keyboard Pump

4 Pages

-

VMECA Midi-Keyboard Pump

12 Pages

-

VMECA Mega-Keyboard Pump

12 Pages

-

VMECA Mini Pump (X type)

4 Pages

-

VMECA Mini Pump (M type)

8 Pages

-

VMECA X Duplex Pump

6 Pages

-

VMECA M- Duplex Pump

6 Pages

-

VMECA Air & Vacuum Manifolds

3 Pages

-

VMECA Vacuum silencers

1 Pages

-

VMECA Pressure Gauges

1 Pages

-

VMECA Vacuum Gauges

1 Pages

-

VMECA Mega Vacuum Filters

1 Pages

-

VMECA Bowl Vacuum Filters

1 Pages

-

VMECA Turtle Vacuum Filters

1 Pages

-

VMECA Line Vacuum Filters

1 Pages

-

VMECA Smart Plungers

12 Pages

-

VMECA VBU series vacuum cups

2 Pages

-

VMECA - Innovated New Products

24 Pages

-

VMECA Vacuum Technology - I

343 Pages

-

VMECA Vacuum Conveyor

32 Pages

-

VMECA VBF-series Suction Cup

4 Pages

-

VMECA Mega Turtle Pump

13 Pages