Catalog excerpts

Ver. 4.1 Oi ISO 9001 CERTIFIED J&VACUUM TECHNOL OGY-I ©VMCA www.vmeca.com

Open the catalog to page 1

ISO 9001 CERTIFIED Vacuum Flow & Quick Response (Improving Productivity) Multi-stage Vacuum Cartridge (High Quality Vacuum Technology) Check Valves (Safety & Speed of Evacuation.) Minimum Compressed Air (Energy Saving) •The “V” in our logo comes from Vacuum technology and “MECA” comes from the Mechanical technology. •By using the vacuum cartridge icon and blue VTEC color, it clearly reminds that “VMECA” is the same brand as VTEC. •The VMECA reflects vacuum and mechanical technologies that combines well and supplies complement system to the customers.

Open the catalog to page 3

VACUUM TECHNOLOGY CONTENTS SUCTION CUPS VACUUM SPEEDER VACUUM PUMPS V-GRIP ACCESSORIES SYSTEM VACUUM TECHNOLOGY Page 4 SUCTION CUPS Page 10 VACUUM SPEEDER Page 75 VACUUM PUMPS Page 103 V-GRIP SYSTEM Page 310 ACCESSORIES Page 317

Open the catalog to page 4

VACUUM TECHNOLOGY 4 Specifications subject to change without notice. www.vmeca.com Vacuum is created with an air-jet system when compressed air (3-6bar) passes at high speed through the pump nozzles. VMECA Vacuum Cartridge is a new and innovative multistage vacuum pump. - It is extremely compact in size and very light weight. - It is “engineering and design friendly” making it easy to create a vacuum pump and system for a specific application or machine. The VMECA Vacuum Cartridge provides a high vacuum flow rate (3x higher) and an extremely quick response time (about 1.5x greater) compared...

Open the catalog to page 5

Be sure to before handling. Safe designs should be developed, which accounts for the possibility of accidents resulting from a drop in vacuum pressure due to power failure or trouble with the air supply, etc. If vacuum pressure drops and there is a loss of vacuum pad adsorption force, work pieces being carried may fall, causing human injury or damage to machinery, Safety measures should be implemented such as the installation of drop prevention guides. Select vacuum pumps which have a suitable suction flow rate. If the vacuum pump suction flow rate is too low, this will cause poor...

Open the catalog to page 6

VACUUM TECHNOLOGY 8 Specifications subject to change without notice. www.vmeca.com Thread Systems Cylindrical metric thread: designated with the letter M. Example M5. Cylindrical inch thread (also called Unified thread): designated with the letter UNF Example 10-32UNF. ISO THREAD: The dry seal system consists of cylindrical and conical pipe-threads. The threads have a 60Bprofile angle and are scaled without packing or seal rings (Please note that when these are used in other combination of thread systems, that “sealing” is not applicable). The dimensions are given in inches and VMECA’s...

Open the catalog to page 9

VACUUM TECHNOLOGY Specifications subject to change without notice. www.vmeca.com 9 VACUUM TECHNOLOGY Applications for vtec vacuum equipment Handling Box for Robotic palletizing Robot industry Pick & place for food industry Plastic bag opening Thin film feeding Packaging machine Panel lifting for Automotive industry

Open the catalog to page 10

SUCTION CUPS L & BJ series (Level Compensator and Ball Joint and Fitting Connector) P.52~53 P.60~67 Fittings for Suction cups P.68~74 VOU series (Oval Universal) VOC series (Oval Curved) KPS series P.56~57 (Plastic Bag Opening) VTEC SUCTION CUP TECHNOLOGY P.11~19 VB series (Bellows) P.20~23 VB-M series (Direct Fitting Bellows) P.24~25 VBF series (Bellows Flat) VBL series (Long Bellows) VU series (Universal) P.26~29 P.30~33 P.34~37 VF series P.38~43 P.44~47 P.48~49 (Flat) VFC series (Flat Curve) VD series (Deep) VS series P.50~51 (Sponge) NF series P.58~59 (Non-touch Flat) SUCTION CUPS P.54~55

Open the catalog to page 11

11 SUCTION CUPS Specifications subject to change without notice. www.vmeca.com SUCTION CUPS 1. Advantages of suction cup Materials’ handling with suction cup is very simple low cost and reliable. It is therefore a solution worth using before considering more complicated handling techniques. Suction cups can lift, and hold objects from a few grams up to several kg. 2. The principle of suction cup Why does a suction cup suck onto the surface it’s placed on? It’s quite simple and is all to do with atmospheric pressure. Atmospheric pressure can generally be defined as the weight of the air...

Open the catalog to page 12

12 Specifications subject to change without notice. www.vmeca.com SUCTION CUPS 3. How to select the suction cup 4. Calculating achievable perpendicular / parallel lifting force (-60kPa=-450 mmHg) D : Suction cup dia. (mm) m : Mass to lift (kg) u : Vacuum level (-kPa) n : Safety factor (2 or 3) s : Quantity of cup Lift : Formula W : Lifting force (N) P : Vacuum level (-kPa) S : Size of suction cup (cm2) n : Safety factor Perpendicular : insert 2 or 3 Parallel : 3 insert or 4 Perpendicular Parallel D =113X U x s m x n W = P x S x 0.1 x nn 11

Open the catalog to page 13

0~0.295 0~0.71 0~2.5 0~3.26 0~5 0~8.67 0~20.4 0~25.51 0~61.22 0~0.295 0~0.86 0~2.5 0~5.1 0~5.81 0~15.3 0~20.4 0~45.9 0~86.7 0~438.7 0~0.098 0~0.23 0~0.83 0~1.08 0~1.66 0~2.89 0~6.8 0~8.5 0~20.4 0~0.008 0~0.44 0~0.81 0~1 0~2.24 0~3.77 0~11.22 0~23.97 0~137.64 0~0.002 0~0.14 0~0.27 0~0.33 0~0.74 0~1.25 0~3.74 0~7.99 0~45.88 Ø2-8 Ø10-15 0~0.005 0~0.17 0~0.31 0~0.81 0~1.12 0~2.19 0~8.16 0~17.5 0~35.0 0~96.9 0~0.145 0~0.43 0~1.25 0~2.55 0~2.9 0~7.65 0~10.2 0~22.9 0~43.3 0~219.3 0~0.01 0~0.34 0~0.63 0~1.63 0~2.24 0~4.38 0~16.32 0~35 0~70 0~193.8 Ø20-25 Ø30-35 Ø40 Ø50-60 Ø75-80 Ø100-115 Ø150...

Open the catalog to page 14

1. Choose the model depending on the shape of object to lift. 2. Choose the size of the cup based on the weight of the object to lift. 3. Choose lie material of the cup based on the working environment and surface texture. 4. Select the fitting size to suit the application. 5. Select the accessory depending on the application i.e.. level compensator or ball joint. 14 Specifications subject to change without notice. www.vmeca.com SUCTION CUPS 6. Applications for suction cups VB (Bellows) The bellows cup is very good at compensating for a degree of difference in level and curvature of the...

Open the catalog to page 15All VMECA catalogs and technical brochures

-

VBF Series

4 Pages

-

Mini Cartridge Catalog

4 Pages

-

Micro Cartridge Catalog

1 Pages

-

VMECA Mega Pm Pump

5 Pages

-

VMECA Micro Cartridge Pump

6 Pages

-

VMECA Mega Pump

4 Pages

-

Maxflex Pump ( L series)

6 Pages

-

VMECA Conveying Pump

4 Pages

-

VMECA V-Pump (VLS series)

5 Pages

-

VMECA V-Pump (VS series)

5 Pages

-

VMECA MD Pump (MDL series)

5 Pages

-

VMECA MD Pump (MD series)

5 Pages

-

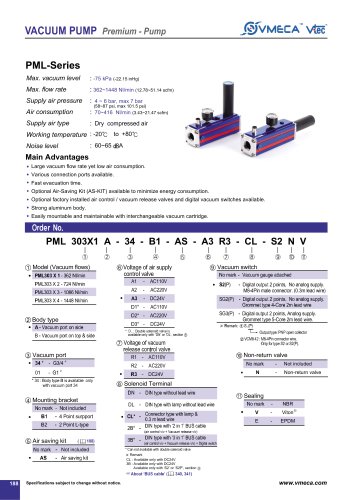

VMECA PM Pump (PML series)

6 Pages

-

VMECA PM Pump (PM series)

6 Pages

-

VMECA Mini-Keyboard Pump

4 Pages

-

VMECA Midi-Keyboard Pump

12 Pages

-

VMECA Mega-Keyboard Pump

12 Pages

-

VMECA Mini Pump (X type)

4 Pages

-

VMECA Mini Pump (M type)

8 Pages

-

VMECA X Duplex Pump

6 Pages

-

VMECA M- Duplex Pump

6 Pages

-

VMECA Air & Vacuum Manifolds

3 Pages

-

VMECA Vacuum silencers

1 Pages

-

VMECA Pressure Gauges

1 Pages

-

VMECA Vacuum Gauges

1 Pages

-

VMECA Mega Vacuum Filters

1 Pages

-

VMECA Bowl Vacuum Filters

1 Pages

-

VMECA Turtle Vacuum Filters

1 Pages

-

VMECA Line Vacuum Filters

1 Pages

-

VMECA Smart Plungers

12 Pages

-

VMECA VBU series vacuum cups

2 Pages

-

VMECA - Innovated New Products

24 Pages

-

VMECA Vacuum Conveyor

32 Pages

-

VMECA VBF-series Suction Cup

4 Pages

-

VMECA Mega Turtle Pump

13 Pages