Catalog excerpts

VACUUM CONVEYOR SYSTEM

Open the catalog to page 1

VACUUM CONVEYOR EC-TYPE EXAMINATION CERTIFICATE (2) EmiiPME vr OK PHnn-KrrnvF. Svsi EM INTENDED EOR USE IN mrrNTiAi I.Y BXFLOSTVI ATMOSPHERES DIREC TIVE [3 | BO Type Ejiaminatiun Certificate Number: IJIW 13 ATFA 28SWX [41 EquipmerU or Praleclive System: VACUUM CONVRVOH |5 | Applicant - Manufkclurcr or Authorized representative: KORFA PNEUMATIC SYSTEM CO., LTT>. Address: #153-817 501-5, POKS AN 1-DOiNG, CEUMCHRON - [7] This equipment or protective system and any Lic cup,table variation thereto is specified in the schedule lo this certificate and the documents (herein referred lo, |SJ DNV,...

Open the catalog to page 2

VACUUM CONVEYOR |14| EC-TYPE EXAMINATION CERTIFICATE No.: DNV I 3 ATEX 2880X if «w r»ui at^Vti hM» m arnif Wstdh m pMov—l f htra bmm* CKUKI fcy any + * catHWIiri atuH »*4 MUM *I OTMI! £«•>•! I* IM *r«« it* tot c*Ji Specifications subject to change without notice

Open the catalog to page 3

VACUUM CONVEYOR ECVTYPRFXAMIXATIOIN CERTIFICATE Nu.i ]>NV IJ ATtfX LI7| Special Conditions fur Safe Use It may only be conveyed bulk muterLLils, thu minimum Lgnilifn :'w(j>i 3 mj in. TKLTC must he na flammable Eases and vapour* may be prcsenl [n Ibe bulk materials or foe transported U}jJcthcf The mam.Lmum fuel tcmpcjalurcof Lbc Ijulk. material must not exceed SO^C, The-delivery of the absorbed bulk material mud not be placed directly in hazardous "Llic uipiratetl material jmuunl may nut exceed- (h«i mass of 10 kg each intake stroke |IJi] Cssttitial Health and Safety Krquii raienl* dapU IT...

Open the catalog to page 4

VACUUM CONVEYOR Why!! We are VMECA Vacuum conveyor system? ► Minimal Maintenance ► Low Noise Level ► Automatic Filter Cleaning System ► Simple to Installation ► Compact Size ► Easy To Clean ► Dustless Conveying ► Acid-Proof ► Polished Stainless Steel ► Easy to Maintenance ► Transports Large Amount ► Atmospheres Explosibles Approval(ATEX) Specifications subject to change without notice

Open the catalog to page 5

VACUUM CONVEYOR Vacuum Cartridge √ Maintains vacuum despite fluctuations in air pressure √ Fast response time √ Selectable cartridge quantity √ Easy maintenance √ Improved to the latest cartridge technology from the classic type of generator. Easy selection and maintenance of VMECA Vacuum Cartridges. Cartridge Filter Easy replacement Pleated media filter Large filter surface area due to a pleated media filter Antistatic filter Food quality Electrically Conductive Polyester with PTFE membrane(cartridge filter) TFE coated antistatic Felt of polyester / Carbon fibers Washable 2 to 4 times in...

Open the catalog to page 6

VACUUM CONVEYOR Atmospheric Pressure Vacuum Conveyor Principle The Vacuum Conveyor utilizes the vacuum to pick up the material for transfer. This process is called a difference in pressure. This is where atmospheric air and the different air pressure tries to equalize itself which in turn creates suction. The same concept is used here when the air within the pipeline is evacuated creating a negative pressure (difference in pressure). This negative pressure has the strength to pull the solid particles through the pipeline and into the Vacuum Conveyor. The below pictures are the order of...

Open the catalog to page 7

VACUUM CONVEYOR The principle of VMECA Conveyor. 1. (D) Hopper Door closes 2. (A) Vacuum Pump starts 3. (H) Shock Tank air energizes 5. (A) Vacuum Pump stops 6. (H) Shock Tank discharges 7. (D) Hopper Door opens - Releases Product Manual injection valve (Hand valve) Automatic injection valve Specifications subject to change without notice

Open the catalog to page 8

VACUUM CONVEYOR FLUIDIZATION Fluidization is necessary for materials that has a poor flowing capacity. The Fluidization works by shooting air into a hopper cone which has small porous openings(similar to a vacuum filter). This air passes through these porous openings allowing the materials inside the conveyor to fully dump. FEED NOZZLE The Feed Nozzle allows the operator to transport the material. It is adjustable by allowing air to flow in with the material. This will create a smooth flow of materials giving it a good air to material ratio to prevent clogging in the pipelines....

Open the catalog to page 9

VACUUM CONVEYOR Injection Valve An Injection Valve is necessary when there is a 90 degree turn. The reason for this is because, if the material is transferred and drops down to the bottom, it runs into dangers of clogging the pipeline. In order to prevent this, an injection valve must be installed near the bend to allow the atmospheric air to come in and discharge the pipeline of any build ups. 1 and 2 = Without the Injection Valve 3 and 4 = With the Injection Valve Installed Specifications subject to change without notice

Open the catalog to page 10

VACUUM CONVEYOR Vacuum Conveyor Model No? How to select a standard conveyor? (Example) The sugar company needs to convey 1.2tons of granulated sugar per hour up to a mixer where the sugar is mixed with cacao powder. The mixer is located 11 meters from the Feed station. Example) VMECA vacuum conveyor “VTC 400” will be the best choice when the Pr = 10 ~ 20 in this Example, The power requirement (Pr) of the applications is the same as the customer’s capacity requirement. Hear the Pr figure, which is the product of capacity and conveying distance, is calculated. ▶ Material : granulated sugar ▶...

Open the catalog to page 11

VACUUM CONVEYOR Series VTC 100 .. Supply air pressure : 4 ~ 6 bar (Max 7bar) (58 ~ 87 psi, Max 101.5 psi) Air consumption Noise level Steel Material Sealing Material Filter Material : 280 ~ 416 Nl/min (9.88 ~ 14.7 scfm) : 68 ~ 76 dBA : SUS304 / SUS316L : Silicone : Electrically conductive polyester with PTFE membrane Ordering information √ Please contact VMECA for ATEX approval conveyor. ● 100 : Vacuum Pump with Free flow exhaust duct (standard) 100 CP : Vacuum Pump with Concentration exhaust port - Extra large B : Bag Filter – Filtering capacity (5µ) B2 : Bag Filter – Filtering capacity...

Open the catalog to page 12

VACUUM CONVEYOR Specification Capacity ton/h at Different Conveying distance Max. Conveying Capacity (ton/h) 8M Rec. Material Pipe Dimension (mm) Rec. Material Volume (l/cycle) Remark) 1. Above data based on actual test result of sugar which is specific gravity 0.85 in vertical 3m with 2 bends 2. The data can be changed according to the condition such as supply air flow, air pressure and condition of pipe line (bending) when conveyor is operating. Specifications subject to change without notice

Open the catalog to page 13All VMECA catalogs and technical brochures

-

VBF Series

4 Pages

-

Mini Cartridge Catalog

4 Pages

-

Micro Cartridge Catalog

1 Pages

-

VMECA Mega Pm Pump

5 Pages

-

VMECA Micro Cartridge Pump

6 Pages

-

VMECA Mega Pump

4 Pages

-

Maxflex Pump ( L series)

6 Pages

-

VMECA Conveying Pump

4 Pages

-

VMECA V-Pump (VLS series)

5 Pages

-

VMECA V-Pump (VS series)

5 Pages

-

VMECA MD Pump (MDL series)

5 Pages

-

VMECA MD Pump (MD series)

5 Pages

-

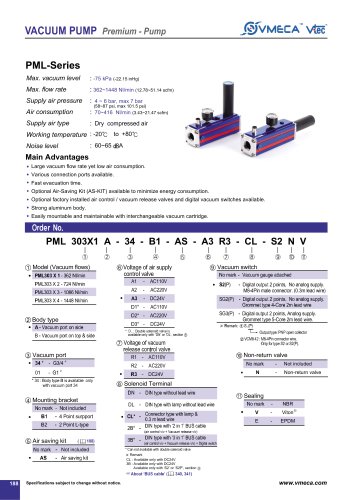

VMECA PM Pump (PML series)

6 Pages

-

VMECA PM Pump (PM series)

6 Pages

-

VMECA Mini-Keyboard Pump

4 Pages

-

VMECA Midi-Keyboard Pump

12 Pages

-

VMECA Mega-Keyboard Pump

12 Pages

-

VMECA Mini Pump (X type)

4 Pages

-

VMECA Mini Pump (M type)

8 Pages

-

VMECA X Duplex Pump

6 Pages

-

VMECA M- Duplex Pump

6 Pages

-

VMECA Air & Vacuum Manifolds

3 Pages

-

VMECA Vacuum silencers

1 Pages

-

VMECA Pressure Gauges

1 Pages

-

VMECA Vacuum Gauges

1 Pages

-

VMECA Mega Vacuum Filters

1 Pages

-

VMECA Bowl Vacuum Filters

1 Pages

-

VMECA Turtle Vacuum Filters

1 Pages

-

VMECA Line Vacuum Filters

1 Pages

-

VMECA Smart Plungers

12 Pages

-

VMECA VBU series vacuum cups

2 Pages

-

VMECA - Innovated New Products

24 Pages

-

VMECA Vacuum Technology - I

343 Pages

-

VMECA Vacuum Conveyor

32 Pages

-

VMECA VBF-series Suction Cup

4 Pages

-

VMECA Mega Turtle Pump

13 Pages