Catalog excerpts

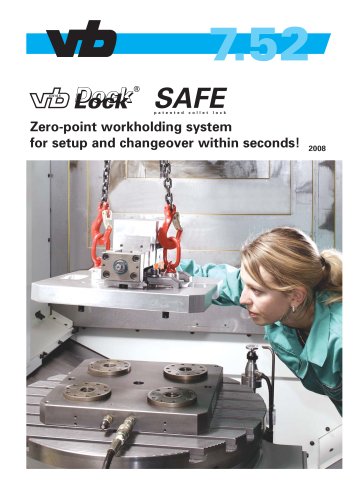

Zero-point clamping SAFE patented collet lock Zero-point clamping since 1995

Open the catalog to page 1

Vischer & Bolli AG – Company headquarters in Dübendorf Switzerland Advice. Orders. Sales Just call us – we are here to help you. Our specialists will be happy to advise you on the products in which you are interested with no obligation. Vischer & Bolli AG Werkzeug- und Spanntechnik Im Schossacher 17 CH-8600 Dübendorf

Open the catalog to page 2

Vischer & Bolli – the tool engineering and workholding professionals: Your wish is our command, our business model is as simple as that. Experience and pioneering spirit. The best possible solutions to suit our customer needs. Suppliers of precision tools since 1957. Many of these tools have been developed by our in-house engineers, including the DockLock zero-point workholding system, a marked leader from which our customers all over the world have benefited since 1995. First class, customized solutions. Rely on us to provide them. Swiss quality is guaranteed by our experts in the fields...

Open the catalog to page 3

Vischer & Bolli The smart move from set-up time to productivity! with existing machine outfit – increase in productivity – increase in return Assuming: 200 working days machining hour € 80.– Set-up change conventional Set-up change with machine down time machine down time additional earning with 1 machine 1 shift 2 set-up change / shift 4 set-up change / shift 5 machine 2 shift 2 set-up change / shift 4 set-up change / shift 4

Open the catalog to page 4

Vischer & Bolli zero-point clamping The zero-point clamping system with patented collet lock Pull-in force per unit: 12’500 N Retention force per unit: 40’000 N Pull-in force per unit: 20’000 N Retention force per unit: 60’000 N Pull-in force per unit: 30’000 N Retention force per unit: 90’000 N Pull-in force per unit: 20’000 N Retention force per unit: 60’000 N Combination base plates Standard base plates Standard- and indexable pallets Pressure units Accessories zero-point clamping 2012

Open the catalog to page 5

The only Zero-point clamping system with a patented collet lock. SAFE patented collet lock Developed for you Made of cold-work corrosion resistant steel Approved design, umpteen thousand sold The modular build up not just guarantees enormous time and cost savings but assures great flexibility in production. The unique interface enables setups where they actually belong, outside the machine tools, without blocking any machining time. Whether it is measuring, turning, milling, grinding or edming, with your production is much more flexible, while costs and delivery time are reduced. Our long...

Open the catalog to page 6

Vischer & Bolli Highest pull-in and retention forces. Mechanically clamped by disc springs released by hydraulic Tilted fixture cause no problem Push up function produces easy handling

Open the catalog to page 7

Vischer & Bolli The smart move from set-up time to productivity: equip your machines with (machine tables or pallets)! mount fixtures with plugs engage and start machining

Open the catalog to page 8

Vischer & Bolli / www.vb-tools.com Pull-in force per unit: 12'500 N Retention force per unit: 40'000 N Flanged cylinders page 10-11 Built-in cylinders page 12-13 Built-up cylinders Page 14 Pneumatically activated units Page 15

Open the catalog to page 9

Vischer & Bolli Flanged cylinders for direct integration into machine tables, pallets and fixtures pull-in force: 12’500 N 752160 752160 L 752160 LU 752160 I Standard with air-blast cleaning with air-blast cleaning and rear side media connection with indexing grooves with air-blast cleaning and indexing grooves with air-blast cleaning, indexing grooves and rear side media connection Indexing grooves Pallets and indexing set screws see page 52 For in-house mounting please ask for instructions! Max. operating pressure 70 bar / 1015 psi

Open the catalog to page 10

Vischer & Bolli / www.vb-tools.com Flanged cylinders for direct integration into machine tables, pallets and fixtures with air-blast cleaning through center 752160 LAK with air-blast cleaning through center and support isles and rear side with air-blast cleaning through center, support isles and piston position monitoring For in-house mounting please ask for instructions! Max. operating pressure 70 bar /1015 psi

Open the catalog to page 11

Vischer & Bolli Built-in cylinders for base-plates, set-up stations, measuring machines pull-in force: 12’500 N 752150 752150 L Standard with air-blast cleaning with indexing grooves with air-blast cleaning and indexing grooves Indexing grooves Pallets and indexing set screws see page 52 For in-house mounting please ask for instructions! Max. operating pressure 70 bar / 1015 psi

Open the catalog to page 12

Vischer & Bolli Built-in cylinders for base-plates, set-up stations, measuring machines pull-in force: 12’500 N 752150 LA with air-blast cleaning through center and support isles For in-house mounting please ask for instructions! Max. operating pressure 70 bar / 1015 psi

Open the catalog to page 13

Vischer & Bolli SAFE 20 Built-up cylinders for flexible configuration Standard with air-blast cleaning with indexing grooves with air-blast cleaning and indexing grooves Indexing grooves Pallets and indexing set screws see page 52 Socket head screw M12x35 751175

Open the catalog to page 14

Vischer & Bolli Pneumatically activated units Flanged cylinders Built-in cyinders 752160 P Standard 752160 LP with air-blast cleaning 752160 LUP with air-blast cleaning and rear side media connection 752160 IP with indexing grooves 752160 LIP with air-blast cleaning and indexing grooves 752160 LIUP with air-blast cleaning, indexing grooves and rear side media connection 752160 LAP with air-blast cleaning through center and support isles 752160 LAUP with air-blast cleaning, through center and support isles and rear side media connection 752160 LAKP with air-blast cleaning through center and...

Open the catalog to page 15

Vischer & Bolli Plugs recommended plug arrangement Centering plug 0 - ground Ø 32 + 0,01 mm - Compensation plug - two ground raised cams 0 Ø 32 + 0,01 mm - Plug without centering The compensation plug defines the X- or Y-axis. The cam line must be set 90° to the line connecting with the centering plug. Compensates for variations in temperature. Plug without centering 0 - Ø 30,0 + 0,1 mm - The centering plug defines the zero-point. It centers with the diameter Plugs without centering only serve for clamping Plug without centering Compensation plug Centering plug

Open the catalog to page 16All Vischer & Bolli AG catalogs and technical brochures

-

Universal 5 Axis Vise

16 Pages

-

INT-CT

64 Pages

-

Inserts

52 Pages