Catalog excerpts

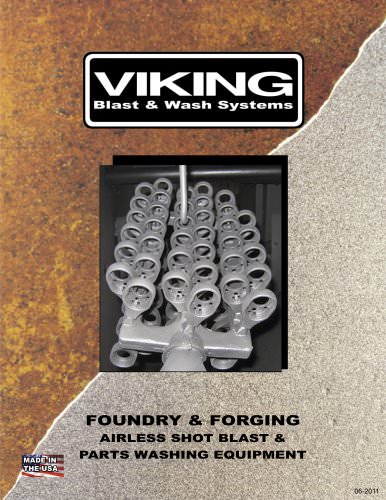

Blast & Wash Systems FOUNDRY & FORGING AIRLESS SHOT BLAST & PARTS WASHING EQUIPMENT

Open the catalog to page 1

CHAINBELT FLOW THROUGH BLASTERS Features: Model CB 3624 Shown • This type of system offers the potential for reducing blaster operation and maintenance cost per cleaned part by 20 to 50% compared to batch-style blast cleaning • Pass-through blasting should also reduce labor costs associated with cleaning by 50 to 90% Model CB 1818 • Utilizes 4, 6, or 8 model VK PowerMax, direct drive blast wheels for complete 360o part coverage • Complete cast chrome/moly lining protects the cabinet from abrasive wear for long life and low maintenance • Manganese belt conveyance system with variable speed...

Open the catalog to page 2

VIBRATORY SHAKERS Vibratory cleaning is the most economical method of batch processing small quantities of parts. Tumbling parts in ceramic or aluminum media is gentle enough to protect delicate parts, however is tough enough to debur and polish. Standard sizes range from 2 to 54 cubic foot capacities. Features: Model 7S Model 54S Shown • Soft rubber pads keep the shaker from walking, reducing noise and eliminating the need to bolt the machine to the floor • Vibratory tub is lined with 1/2" thick urethane body liner and a 3/8" thick manganese end liners ensuring long life • Totally enclosed...

Open the catalog to page 3

TUMBLE BELT BLASTERS Viking Steel Belt Blasters are ideal for blasting hot castings or forgings that can be tumbled. These machines can process much heavier parts than the Rubber Belt Style. Available in standard 7 and 14 cubic foot capacities, with custom sizing available to t specic applications. Model 700S Shown Features: • Heavy duty replacement manganese slats bolt to heavy duty cast chrome link chain. • Fully adjustable lip type airwash separator ensures optimal abrasive cleaning • Pneumatic blast cabinet door Model 600 Shown • High velocity center-fed blast wheels • 5-30 HP blast...

Open the catalog to page 4

Model SH1545 Shown INDEXING SPINNER HANGERS Features: • Cast lined blast chambers • Custom casting or forging fixture designs Model SH 2560 Shown • Heavy duty abrasive recycling system • Manganese wheel housing and cast chrome liners providing long wear life • Light curtain protection for operator safety • Easy access doors provided where maintenance is required • Available in 5 to 40 HP wheel configurations • Heavy duty cabinet and auger system construction Optional Features: • Multiple zone blasting • Rotary scalp drum • Continuous duty, cartridge type dust collector Viking airless,...

Open the catalog to page 5

CUSTOMIZATION It is in the customization of our basic designs to your castings specic needs that truly sets Viking apart from the competition. With an accomplished and proven design staff, Viking can build equipment from the ground up or simply modify existing models to tailor t your cleaning application. At Viking we do not simply match your casting to the closest machine size that will work. We match our blast equipment to your part, to provide the most efcient and economical cleaning solution possible. REPLACEMENT PARTS Superior parts and service sets Viking’s Parts Department apart from...

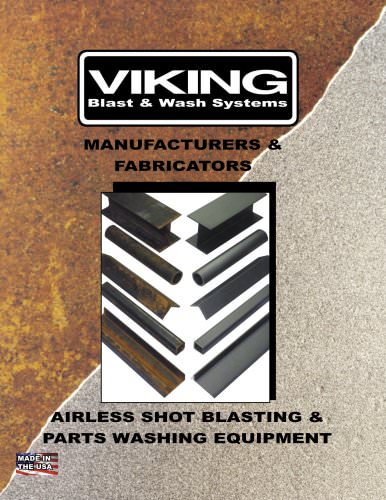

Open the catalog to page 6All Viking Blast Systems catalogs and technical brochures

-

Indexing turntable

2 Pages

-

Blast Rooms

2 Pages

-

Propane Brochure

6 Pages

-

Dust Collector Brochure

8 Pages

-

Industrial Washer Catalog

16 Pages