Catalog excerpts

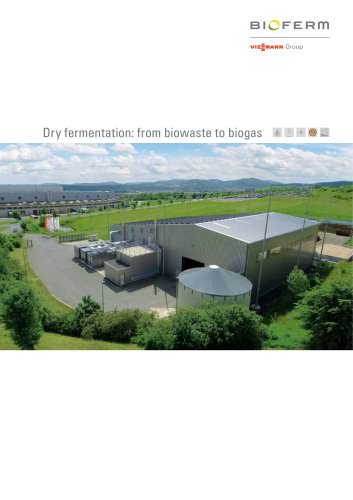

VIE|MANN Group Local energy production from biowaste 4>lll © 8

Open the catalog to page 1

The BIOFerm system creates biogas from organic waste 30 to 40 per cent of the volume of residential waste in Germany is organic waste. The nationwide collection of biowaste offers enormous potential. This waste can be converted to energy in biogas plants at minimal cost. The largest as yet untapped potential lies in the field of biowaste and landscape conservation material. These elements have so far been to a large extent composted or sent unsorted to landfill sites instead of being used to generate energy. Waste is a resource – as part of the economic cycle BIOFerm offers a comprehensive...

Open the catalog to page 3

BIOFerm process – modern waste treatment Dry fermentation for stackable, organic solids Schmack Biogas offers the BIOFerm dry fermentation technology in its portfolio for non-pumpable feedstock. The demands made on the source material are extremely low. The process is ideal for stackable, organic solids, such as biowaste, green matter and solid manure containing up to 60 per cent dry matter content. Common features of industrial or municipal biowaste include: high proportion of impurities (plastic, wood, metal etc.) high dry matter content heterogeneous substrate composition not always...

Open the catalog to page 5

Biowaste fermentation technology Recycling waste – the BIOFerm system Dry fermentation: ideally suited The BIOFerm system works on a batch process, which means that the digesters are periodically emptied and then refilled. In the reception hall a wheeled loader mixes the stackable fresh material with the previously fermented material (a process also known as „seeding“) and feeds it into the garageshaped digesters. After approx. four weeks the digester is completely emptied and refilled with a seeded mixture. for organic and green waste The majority of the plant and measurement technology is...

Open the catalog to page 6

Economic benefits from tried and tested technology Greater returns with robust and reliable components Dry fermentation technology is constantly evolving in terms of efficiency, ease of maintenance and economic viability. A great many tried and tested components from the Schmack wet fermentation system were transferred to the BIOFerm system as a result. Technical adaptation Garage digester roof structure Optimised drainage system Percolate tank as round fermenter with double membrane roof External gas storage Optimised roof structure The digester‘s roof has no housing, following the design...

Open the catalog to page 7

Flexible substance handling thanks to combined technology Integrating different biogas technologies enables the maximum exploitation of all source materials In conventional biowaste fermentation, the source substrate is extremely heterogeneous. Furthermore, the material input varies according to the season. The expected gas yields from biowaste are therefore highly variable. Hybrid system: Tried and tested technology, new process benefits Since not all biogenic residues are suitable for dry fermentation, they have to be used in socalled hybrid systems (combined wet and dry fermentation). The...

Open the catalog to page 8

Technical and biological service to secure maximum yields Our responsibility: maximum availability for your plant Even after the biogas plant has been built, BIOFerm customers can rely on a comprehensive technical and biological service. With the Schmack service concept, our customers secure the operational reliability of their plant and keep their performance at a permanently high level. Technical service: Professional and fast For us, customer service begins long before any component wears or needs replacement – through qualified advice, preventative maintenance and appropriate planning by...

Open the catalog to page 9

Our specialists ensure a perfect result

Open the catalog to page 10

Expertise in biogas The actual hours run under full load each year is the crucial dimension for checking the viability of a biogas plant. Schmack Biogas is committed to standard plant technology and extensive processbi logical know-how. Many years of experience in both sectors enable the company to guarantee above average utilisation to both investors and operators. Reliability With round the clock supervision through the EUVIS control centre, downtime of supported plants can be reduced to a minimum. Prevention of idle times through scheduled and specific service and maintenance deployments...

Open the catalog to page 11

BIOFerm biogas plants – Full output in constant use Their good performance makes our biogas plants stand out year after year. They operate with great reliability, whatever their size or system design. Sogliano Ambiente (Italy) Installed output: 1 MW (electrical) Throughput p. a.: 40 000 t biowaste and household refuse Number of digesters: 11 Digester size: 30 x 7 x 5 m (Length x Width x Height) Construction started: July 2011 Commissioning: February 2013 Viessmann Biomasse KG (Germany) Installed output: 190 kW (electrical) Throughput p. a.: 4 500 t (landscape conservation material) Number...

Open the catalog to page 12

Fife (Scotland) Installed output: 1.8 MW (electrical) Throughput p.a.: 40 000 t biowaste (brown bins) and 3 000 t food waste Number of digesters: 14 Digester size: 30 x 7 x 5 m (Length x Width x Height) Construction started: February 2012 Commissioning: July 2013 Stausebach (Germany) Installed output: 4 MWGas Throughput p.a.: 30 000 t/a biowaste and 15 000 t/a Energy crops (combi-plant) Number of digesters: 8 Digester size: 35 x 6.75 x 5 m (Length x Width x Height) Construction started: May 2013 Commissioning: August 2014

Open the catalog to page 13

Viessmann – climate of innovation Viessmann is one of the world's leading manufacturers of intelligent, convenient and efficient systems for heating, cooling and decentralised power generation. As a third generation family run business, Viessmann has been supplying highly efficient and clean heating systems for many decades. the needs of today are met without compromising the quality of life of future generations. We consider climate protection, environmental responsibility and resource efficiency to be key priorities throughout our company, which has more than 11,500 employees worldwide....

Open the catalog to page 15All Viessmann Werke GmbH & Co KG catalogs and technical brochures

-

Vitocal 150-A/151-A

20 Pages

-

Vitocal 200-A

4 Pages

-

Vitodens 200-W

4 Pages

-

Vitodens-222-F

4 Pages

-

Vitodens 050-W

4 Pages

-

Product Range Overview

20 Pages

-

Photovoltaic systems

20 Pages

-

Hybrid solutions

24 Pages

-

Gas condensing technology

40 Pages

-

Oil condensing technology

32 Pages

-

Etanomics

16 Pages

-

Wood boilers

42 Pages

-

Heat pumps

72 Pages

-

DHW cylinder Vitocell

36 Pages

-

Power to gas

4 Pages

-

Mechanical ventilation systems

36 Pages

-

Thermal solar systems

34 Pages

-

Gas processing plants

16 Pages

-

Power-generating heating systems

24 Pages

-

Wood boilers from 8 to 170 kW

42 Pages

-

Gas condensing technology

48 Pages

-

Fuel cell boiler

16 Pages

-

Solutions generating energy

24 Pages

-

Heat pumps up to 2000 kW

40 Pages

-

CHP units for heat and power

20 Pages

-

Biogas upgrading plants

20 Pages

-

Energy from the sun

46 Pages

-

VITOTWIN 300-W

4 Pages

-

DHW cylinders Vitocell

32 Pages

-

Micro CHP boiler

12 Pages

-

A perfect climate for your home

20 Pages

-

Heating with wood

56 Pages

-

Power from the sun

20 Pages

-

Heating with gas

74 Pages

-

Heating with oil

72 Pages