Catalog excerpts

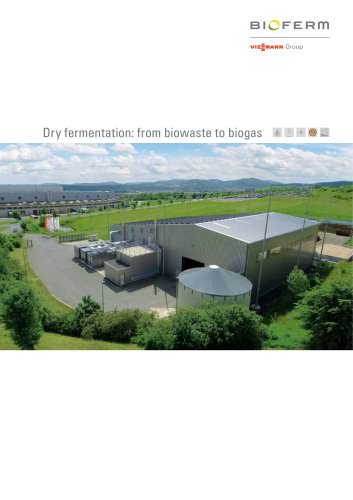

VIE|MANN Group Dry fermentation: from biowaste to biogas * HS^

Open the catalog to page 1

Biogas – clean energy with a big future BIOFerm is the dry fermentation specialist in the Viessmann Group. We make a real contribution to CO2-neutral energy generation with innovative technologies. Since 2007 BIOFerm has been a member of the Viessmann Group, one of the internationally leading manufacturers of heating systems. The resulting technological synergies in the areas of gas utilisation and heat generation provide real benefit to our customers. With sites in Germany and around the world, we can realise international projects in the closest proximity to our customers. BIOFerm offers...

Open the catalog to page 3

The BIOFerm system: turning biomass into valuable energy Biomass Mixing area Digester Gas storage Heating technology Combined heat and power unit Cooling/heat utilisation Power feed into the grid The fermentation of biomass forms high quality biogas with a high methane and low hydrogen sulphide content. BIOFerm relies on dry fermentation when generating biogas. Compared to wet fermentation, the demands this process makes of the source material are extremely low. Any organic solid mass that can be tipped, such as biowaste, cuttings and solid manure with up to 60 percent dry matter can be...

Open the catalog to page 5

Economy Service Economy from which you profit both now and in years to come Biogas from biomass is not only ecologically sensible, but also highly profitable Our advice Combined heat and power units (CHP) are ideal for operating with biogas. For detailed information regarding CHP modules from ESS, the CHP expert in the Viessmann Group, see the brochure “CHP units for heat and power”. For further information see also www.viessmann.de Sizing the biogas plant accurately is essential to effect the most efficient and economical operation. BIOFerm technology enables the conversion of biowaste and...

Open the catalog to page 6

Tailor-made technical and biological service Technical and biological service to safeguard maximum yields BIOFerm customers can rely on an extensive range of technical and biological services even after their biogas plant has been completed. All services are delivered by our affiliate Schmack Biogas Service GmbH. With the elements that comprise the Schmack Service Concept, our customers are able to safeguard the operational availability of their plant and keep it permanently at peak performance. Competent and fast technical service For us, customer service begins long before any component...

Open the catalog to page 7

BIOFerm biogas plants – full output in constant use Our biogas plants stand out through their high performance. They operate with great reliability whatever their size or system design. Società Agricola Aziende L. Bennati S.p.a., San Canzian D`Isonzo (Italy) Installed output: 910 kW (electrical) Throughput p.a.: 28,000 t (NawaRo) Number of digesters: 11 Digester size: 30 x 7 x 5 m (length x width x height) Construction starts: August 2009 Commissioning: March 2010 Fortex, Sumperk (Czech Republic) Installed output: 526 kW (electrical) Throughput p.a.: 12000 t (NawaRo) Number of digesters: 6...

Open the catalog to page 8

Viessmann Biomasse KG, Allendorf (Eder) Installed output: 190 kW (electrical) Throughput p.a.: 4500 t (waste from landscape operations) Number of digesters: 4 Digester size: 20 x 7 x 4.50 m (length x width x height) Construction starts: September 2009 Commissioning: August 2010 Biomethan Moosdorf Installed output: 460 kW (electrical) Throughput p.a.: 13,000 t (biowaste, cuttings) Number of digesters: 7 Digester size: 30 x 7 x 4 m (length x width x height) Construction starts: March 2007 Commissioning: December 2007 Special aspects: Micro gas network with Viessmann biogas boiler

Open the catalog to page 9

The comprehensive Viessmann product range Boilers for oil up to 116 MW heating or 120 t/h steam output Boilers for gas up to 116 MW heating or 120 t/h steam output Solar thermal systems and photovoltaics Detached houses Apartment buildings Commerce / Industry Local heating networks Individual solutions with efficient systems The comprehensive Viessmann product range The comprehensive product range from Viessmann offers individual solutions with efficient systems for all applications and all energy sources. For decades, the company has been supplying highly efficient and clean heating...

Open the catalog to page 10

Wood combustion biogas production Heating system The comprehensive product range from Viessmann ndividual solutions with efficient systems for all energy The product range for all fuel types and output ranges: ■ Solar thermal systems ■ Wood combustion systems up to 50 MW ■ Combined heat and power modules up to ■ Systems for the production of biogas from ■ Biogas upgrading plants up to 3000 m3/h ■ Heating system accessories Viessmann is highly specialised in all these market segments, yet at the same time the company has a crucial advantage over specialist suppliers: Viessmann understands...

Open the catalog to page 11

The comprehensive Viessmann product range Detached houses Apartment buildings Commerce / Industry Local heating networks Ameco A380 Hangar Beijing, European Parliament, Strasbourg, Garden Xi'an, China Detached house, Kevelaer, "Wohnoase" residential park in Porsche Leipzig, European Parliament, Brussels, Regensburg, Germany Heliotrop Freiburg, HafenCity, Hamburg, City of Tomorrow, Malmö, Detached house, Wiesloch, Hotel Lagorai Cavalese, Congressional Centre, Brunstad, Norway Loftcube Regional Garden Studio flats, Brandenburg, University library, Bamberg, Residential estate, Pfäffikon, Show,...

Open the catalog to page 12

Futureproof heating technology for all requirements Energy consumption worldwide has doubled since 1970 and will triple by 2030. The result: The fossil fuels, oil and gas, are dwindling, energy prices are on the rise and excessive CO2 emissions continue to affect our environment. Energy efficiency is a must if we want our future to be secure. In these projects, Viessmann again and again faces up to the most varied challenges to supply efficient heating technology by offering innovative solutions – in historical listed buildings as well as in modern industrial complexes and the large-scale...

Open the catalog to page 13All Viessmann Werke GmbH & Co KG catalogs and technical brochures

-

Vitocal 150-A/151-A

20 Pages

-

Vitocal 200-A

4 Pages

-

Vitodens 200-W

4 Pages

-

Vitodens-222-F

4 Pages

-

Vitodens 050-W

4 Pages

-

Product Range Overview

20 Pages

-

Photovoltaic systems

20 Pages

-

Hybrid solutions

24 Pages

-

Gas condensing technology

40 Pages

-

Oil condensing technology

32 Pages

-

Etanomics

16 Pages

-

Wood boilers

42 Pages

-

Heat pumps

72 Pages

-

DHW cylinder Vitocell

36 Pages

-

Power to gas

4 Pages

-

Mechanical ventilation systems

36 Pages

-

Thermal solar systems

34 Pages

-

Gas processing plants

16 Pages

-

Power-generating heating systems

24 Pages

-

Wood boilers from 8 to 170 kW

42 Pages

-

Gas condensing technology

48 Pages

-

Fuel cell boiler

16 Pages

-

Solutions generating energy

24 Pages

-

Heat pumps up to 2000 kW

40 Pages

-

CHP units for heat and power

20 Pages

-

Biogas upgrading plants

20 Pages

-

Energy from the sun

46 Pages

-

VITOTWIN 300-W

4 Pages

-

DHW cylinders Vitocell

32 Pages

-

Micro CHP boiler

12 Pages

-

A perfect climate for your home

20 Pages

-

Heating with wood

56 Pages

-

Power from the sun

20 Pages

-

Heating with gas

74 Pages

-

Heating with oil

72 Pages