Catalog excerpts

Biogas upgrading plants

Open the catalog to page 1

The Carbotech system: From Biogas to Biomethane Biomethane gas is an attractive alternative to fossil fuels. Its production is environmentally responsible, efficient and renewable. It can be mixed with natural gas and injected into conventional gas pipelines. Supplies of fossil fuels such as coal, crude oil and natural gas are gradually running out and the effects can already be seen in ever increasing energy prices. For this reason, the introduction of renewable energies into the market is crucial, and it is here that biogas can play an important part. Producing biogas from sustainable raw...

Open the catalog to page 3

Efficient and environmentally responsible production of biomethane Biogas is upgraded into biomethane by means of the pressure swing adsorption process developed by Carbotech. Simple and reliable technology The biogas upgrading process from Carbotech is a simple procedure. The raw biogas is first compressed, following the condensation of water content through a temperature exchange system. Then follows the removal of trace elements, such as hydrogen sulphide (H2S), using activated carbon. As an option, the ZETECH4® system can be implemented. It represents a unique and emission free patented...

Open the catalog to page 5

Gas to grid injection system from Carbotech. Economical planning and future proof investment in sustainable energy Carbotech makes a vital contribution to the development of sustainable energy systems with its operationally reliable and environmentally responsible plants for the upgrading and gas to grid injection of biomethane gas. The Federal Government of Germany has set a target of six billion cubic meters of biomethane to be fed into the natural gas grid by 2020. According to the latest survey, Germany consumed around 100 billion standard cubic meters of natural gas. According to a...

Open the catalog to page 6

How much gas will be produced? When planning a biogas plant it is essential to calculate the amount of raw gas that is going to be produced. The main factor to consider is the amount of feedstock available for the fermentation process, such as organic waste, energy crops or liquid manure. Biomethane Gas to Grid Injection Plants (BtG) The entire gas to grid injection plant is designed, built and tested in accordance with the German Gas Regulations and Standards (DVGW). The complete containerised system is pre-assembled and fully tested at the factory. As a result, installation and...

Open the catalog to page 7

Biogas upgrading plant, Wüsting/ Oldenburg, Ostfriesland. Carbotech – leading in Europe The raw gas for the upgrading plant in Bern (Switzerland) is yielded from sewage gas and waste. BUP Wüsting Owners: EWE AG Location: Wüsting/Oldenburg (Ostfriesland) Commissioning: 08/2009 Plant type: BGAA1200 Source of raw biogas: Energy crops Raw biogas: 1200 Nm3/h Biomethane: 635 Nm3/h Gas quality: DVGW G260 und G262 Plant operation: Automatic, remote monitoring (DSL), local support by biogas plant operator Regular maintenance: Twice annually – achine maintenance M (compressor and pumps) – as alarm...

Open the catalog to page 8

Biogas is the source product for the BUP The Minden-Lübbecke district operates its biogas upgrading plant with waste. BUP Pohlsche Heide Owners: AML Immobilien GmbH Location: Hille, Minden-Lübbecke district Commissioning: 09/2009 Plant type: BGAA500 Source of raw biogas: Municipal waste Raw biogas: 500 Nm3/h Biomethane: 258 Nm3/h Gas quality: DVGW G260 und G262 Plant operation: Automatic, remote monitoring (DSL), local support by biogas plant operator Regular maintenance: Twice annually – achine maintenance M (compressor and pumps) – as alarm sensors G (calibrating) – Analyser (calibrating)...

Open the catalog to page 9

Biogas upgrading plant Emmertsbühl/Blaufelden. Easy handling on site with turnkey container model. BGAA Güterglück Owners: RWE AG Location: Güterglück/Sachsen-Anhalt Commissioning: 07/2009 Plant type: BGAA1200 Source of raw biogas: Energy crops Raw biogas: 1200 Nm3/h Biomethane: 635 Nm3/h Gas quality: DVGW G260 und G262 Plant operation: Automatic, remote monitoring (DSL), local support by biogas plant operator Regular maintenance: Twice annually – achine maintenance M (compressor and pumps) – as alarm sensors G (calibrating) – Analyser (calibrating) – H2S activated carbon (demand-dependent)...

Open the catalog to page 10

In Wrams, food and slaughterhouse waste is Delivery of the container module for converted into valuable biomethane. BGAA Wrams Owners: E.ON Gas Sverige AB Location: Wrams/Sweden Commissioning: 10/2006 Plant type: BGAA500 Source of raw biogas: Food and slaughterhouse waste Raw biogas: 500 Nm3/h Biomethane: 324 Nm3/h Gas quality: DVGW G260 und G262 Plant operation: Automatic, remote monitoring (DSL), local support by biogas plant operator Regular maintenance: Twice annually – achine maintenance M (compressor and pumps) – as alarm sensors G (calibrating) – Analyser (calibrating) – 2S activated...

Open the catalog to page 11

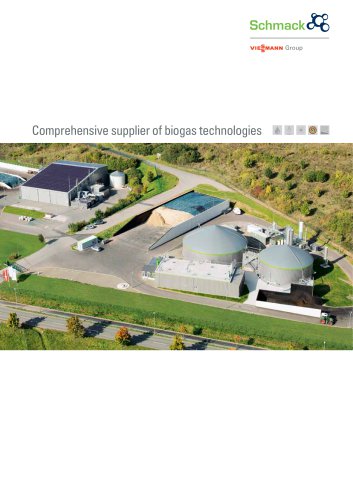

Integrated solutions for the production and utilisation of biogas In the development and construction of plants for biogas and industrial gases, Carbotech from Essen draws on the support of renowned German specialists. Carbotech has its roots in the research and development of processes carried out in the German coal mine industry. Thus, the company’s extensive knowledge base draws on more than 40 years of experience in the development, engineering and manufacturing of turn-key plants for gas upgrading and gas production. The company, which is part of the Viessmann Group, offers integrated...

Open the catalog to page 12

Plants for generating hydrogen and nitrogen for various industries Carbotech can draw on extensive experience with industrial gas purification processes, for example of hydrogen, or the generation of nitrogen. Hydrogen recovery from hydrogen-rich raw gases Pressure swing adsorption plants for the generation of hydrogen from various hydrogen-rich raw gases are state of the art and in operation all around the world. These raw gases may be reformer gases from natural gas, ammonia or naphtha, or coke oven gas, ammonia tail gas or similar. Carbotech has been designing and optimising such plants...

Open the catalog to page 13All Viessmann Werke GmbH & Co KG catalogs and technical brochures

-

Vitocal 150-A/151-A

20 Pages

-

Vitocal 200-A

4 Pages

-

Vitodens 200-W

4 Pages

-

Vitodens-222-F

4 Pages

-

Vitodens 050-W

4 Pages

-

Product Range Overview

20 Pages

-

Photovoltaic systems

20 Pages

-

Hybrid solutions

24 Pages

-

Gas condensing technology

40 Pages

-

Oil condensing technology

32 Pages

-

Etanomics

16 Pages

-

Wood boilers

42 Pages

-

Heat pumps

72 Pages

-

DHW cylinder Vitocell

36 Pages

-

Power to gas

4 Pages

-

Mechanical ventilation systems

36 Pages

-

Thermal solar systems

34 Pages

-

Gas processing plants

16 Pages

-

Power-generating heating systems

24 Pages

-

Wood boilers from 8 to 170 kW

42 Pages

-

Gas condensing technology

48 Pages

-

Fuel cell boiler

16 Pages

-

Solutions generating energy

24 Pages

-

Heat pumps up to 2000 kW

40 Pages

-

CHP units for heat and power

20 Pages

-

Energy from the sun

46 Pages

-

VITOTWIN 300-W

4 Pages

-

DHW cylinders Vitocell

32 Pages

-

Micro CHP boiler

12 Pages

-

A perfect climate for your home

20 Pages

-

Heating with wood

56 Pages

-

Power from the sun

20 Pages

-

Heating with gas

74 Pages

-

Heating with oil

72 Pages