Catalog excerpts

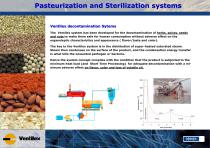

Pasteurization and Sterilization systems Ventilex decontamination Sytems The Ventilex system has been developed for the decontamination of herbs, spices, seeds and nuts to make them safe for human consumption without adverse effect on the organoleptic characteristics and appearance ( flavor/taste and color). The key to the Ventilex system is in the distribution of super-heated saturated steam. Steam then condenses on the surface of the product, and the condensation energy transfer is what kills the unwanted pathogen or bacteria. Hence the system concept complies with the condition that the product is subjected to the minimum heat load (and Short Time Processing) for adequate decontamination with a minimum adverse effect on flavor, color and loss of volatile oil. whole black pepper

Open the catalog to page 1

Pasteurization and Sterilization systems SYSTEM ADVANTAGES Minimal loss of flavor, color and volatile oil. Menu based (for processing multiple products) Industry Standard Data Logger—Stores data of all critical data permanently Automatic cleaning and disinfecting (CIP) Product is decontaminated, dried and cooled Robust and Hygienic design Continuous or batch operation Low energy and Maintenance costs Equiped with self-cleaning rotary discharge valve : less than 10.000 and often less than 1.000 Minimal handling (one operator) More than 100 systems installed worldwide for the sterilization,...

Open the catalog to page 2All Ventilex BV catalogs and technical brochures

-

sugar dryer

4 Pages

-

sand dryer

4 Pages

-

salt dryer

4 Pages

-

Gypsum dryer

4 Pages

-

fertilizer dryer

4 Pages

-

dry scrubber

4 Pages

-

DDGS dryer

4 Pages

-

Fluid bed

16 Pages

-

POLYKATH SYSTEM

2 Pages

-

Sugar Drying Equipment

4 Pages

-

Breadcrumb production lines

5 Pages

-

Fluid Bed Roasting

4 Pages

-

Sludge dryers

5 Pages

-

Steriliser

7 Pages

-

Almond / Nuts pasteurizer

2 Pages

-

Belt dryer

4 Pages

-

Imtech Drying Technology

12 Pages