Catalog excerpts

CONTINUOUS STEAM DECONTAMINATION OF SPICES & HERBS, SEEDS AND NUTS Spices, herbs, seeds and nuts and dehydrated vegetable substances bring a world of flavours, aromas and colours to food. The potential for pathogens like salmonella, yeasts, moulds, enterobacteraceae and sporeformers to get into the food supply has resulted in the trend towards more stringent Good Agricultural Practices and regulations. Spices, herbs are sourced worldwide and they may be heavily contaminated from the soil where they were grown and harvested. These microbes often remain after local processing due to simple treatments and processing at low temperatures. If left untreated, these products may encounter continued microbial growth that can easily lead to spoilage and consumer health issues. There are many commonly used methods to decontaminate natural products, such as ethylene oxide and irradiation but most have been or will soon be restricted due to their potential health risks and adverse consumer acceptance. Ventilex Steam Sterilization Benefits: A natural, renewable process that utilizes steam and is accepted worldwide as safe and wholesome Continuous decontamination of bacteria and pathogens – 5 log kills are typical High-temperature, short-time processing (HTST) which protects the taste, texture, and color of the product and a minimal loss of volatile oil Very gentle for leavy products Fluid bed sterilization of spices & herbs Ventilex continuous steam sterilization: Natural elimination of bacteria The use of steam is ideal as it is natural, inexpensive and can be produced in an unlimited supply. It is a natural “organic” process that does not leave behind any chemical residue or create toxins. Steam pasteurization / sterilization systems are the most effective “natural” method for reducing or eliminating bacteria, pathogens, and other food-borne causes of sickness. Effective steam treatment will eliminate listeria, salmonella, E. Coli, and a variety of other bacteria and pathogens. As a result, many of the world’s largest spice, herb and nut processing companies have selected Ventilex Continuous Steam Sterilizers/Pasteurizers. More than 100 systems have been supplied worldwide.

Open the catalog to page 1

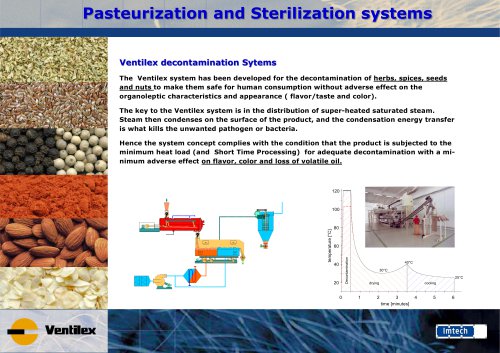

Modern, hygienic and chemical free Steam Treatment Process Steam Sterilizer or Steam pasteurizer With the Ventilex system, you get a continuous “inflow” of high pressure steam that results in the elimination of undesired micro-organisms while causing the minimum harm to the organoleptic characteristics (flavor, color, texture or taste) of spices, herbs and nuts. We offer two different technologies of decontamination systems commonly referred to as “steam sterilizers” and “steam pasteurizers.” Our system can be used to process chili powders, whole and ground pepper, paprika, garlic, cloves...

Open the catalog to page 2

How Does Ventilex Steam Decontamination Work? The process works by feeding and discharging the product through a self-cleaning pressure rotary valve that isolates an autoclave from the ambient room. Inside this autoclave, a shaking table transports product through a steam-pressurized chamber at a specific speed and creates a thin layer of product. Condensation builds on the product surface and this imparts high energy into the surface of the product. This kills unwanted bacteria and pathogens. The time, pressure and steam temperature within the chamber is tightly controlled – just the...

Open the catalog to page 3

Ventilex Sterilization / Pasteurization System features Minimal operator intervention – automated controls; operator only needs to select the right recipe, setpoints are always the same. Data Logging and PLC instrumentation, which makes processes repeatable and verifiable. Stores all critical data permanently Automatic Sanitary Clean-in-Place (CIP) design – fastest system to clean on the market today Recipe based (for processing multiple products) - validated process Hygienic design, high quality finish Product is decontaminated, dried and cooled Shortest duration of steam of any commercial...

Open the catalog to page 4All Ventilex BV catalogs and technical brochures

-

sugar dryer

4 Pages

-

sand dryer

4 Pages

-

salt dryer

4 Pages

-

Gypsum dryer

4 Pages

-

fertilizer dryer

4 Pages

-

dry scrubber

4 Pages

-

DDGS dryer

4 Pages

-

Fluid bed

16 Pages

-

POLYKATH SYSTEM

2 Pages

-

Sugar Drying Equipment

4 Pages

-

Breadcrumb production lines

5 Pages

-

Fluid Bed Roasting

4 Pages

-

Sludge dryers

5 Pages

-

Steriliser

7 Pages

-

Almond / Nuts pasteurizer

2 Pages

-

Belt dryer

4 Pages

-

Imtech Drying Technology

12 Pages