Website:

VELMEX, Inc.

Website:

VELMEX, Inc.

Group: Velmex

Catalog excerpts

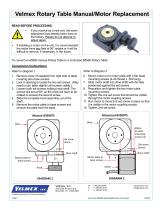

Velmex Rotary Table Manual/Motor Replacement READ BEFORE PROCEEDING • • If you receive as a new unit, the worm adjustment has already been done at the factory. Please do not attempt to adjust again. If installing a motor on the unit, it is recommended the motor have two flats at 90° angles or it will be difficult to remove, if necessary, in the future. To convert an A5990 manual Rotary Table to a motorized B5990 Rotary Table: Conversion Instructions Refer to Diagram 1 1. Remove cover (if needed) from right side of table covering set screw access. 2. Look in opening to locate the two set screws. (May need to turn table slightly until screws visible.) 3. Loosen both set screws holding knob shaft. The screws are set at 90º, so the knob will have to be rotated to access the second screw. 4. Slide the complete knob assembly out of the shaft. 5. Remove the motor plate to base screws and remove the plate from the base. 6. Mount motor on to motor plate with 4 flat head mounting screws (4-40 thread x .500 long). 7. Slide motor shaft into drive shaft with the flats positioned against the set screws. 9. Reposition and tighten the two motor plate mounting screws. 10. Tighten the one set screw that should be visible through the motor coupling access. 11. Run motor to move 2nd set screw in place so that it is visible in the motor coupling access. 12. Tighten 2nd set screw. Motor to plate mounting screws (4) Set screw access. Drive shaft Drive shaft Motor plate to base screws Motor plate to base screws 7550 State Routes 5 & 20 Bloomfield, NY 14469-9389 www.velmex.com info@velmex.com Positioning Systems for Science and Industry Page 1

Open the catalog to page 1All VELMEX catalogs and technical brochures

-

UNISLIDE® TA SYSTEM LAYOUT

1 Pages

-

Limit Switches

7 Pages

-

Rotary-incremental-encoder

3 Pages

-

Velmex Catalog

149 Pages

-

Linear and Rotary Encoders

5 Pages

-

XSlide Spec Overview

8 Pages

-

VRO™ Digital Readout Spec Sheet

10 Pages

-

Rotary-Encoder-Lead-Screw

12 Pages

-

Magnetic_Encoder

1 Pages

-

Inductive_LinearTapeEncoders

15 Pages

-

PK296B2A-SG36,_StepperMotor

3 Pages

-

PK296B2A-SG18,_StepperMotor

3 Pages

-

PK296B2A-SG10,_StepperMotor

3 Pages

-

PK264-03A,_StepperMotor

2 Pages

-

PK243A1A-SG18,_StepperMotor

2 Pages

-

Lead Screw Translation

6 Pages

-

VXM Full Command Summary

3 Pages

-

VXM Controller

8 Pages

-

UniSlide

16 Pages

-

TA System 7-1-14 Rev C

4 Pages

-

BiSlide Side Knob

2 Pages

-

BISlide Catolog

16 Pages

Archived catalogs

-

VRO Overview

5 Pages