Catalog excerpts

SEAT VALVES Veljan Seat Valves are body type mounting series VD4S and cartridge units series VCAR. The complete range of cartridges - body mounted VD4S and manifold mounted VCAR are sized from 3/8" to 1 1 /2" permit flows from The interface porting on the subplate body versions follow CETOP, ISO and DIN standards and is dimensionally identical with the VELJAN VR4 series of pressure controls. Hence VD4S and VR4 valves can be conveniently used in combined circuitry The modular design is used in all valve sizes and the valves are used for a variety of functions : - As a leak - proof directional control - As a pressure control for the adjustment - As a check valve to obtain unidirectional flow - As a throttle valve to control and limit the A variety of standard combinations of internal components are available along with additional options to suit speda circuitry. These options are : - Poppet stroke limiter : to control maximum flow rate, -Vent valve sandwiched : to electrically control poppet operation, -Seatarea changes : to vary operational characteristics, To take pilotoil from Port Aand Port B. Advantages of VCAR cartridge valves are that when integrated with specially designed manifold blocks they offer space and cost savings in comparison with conventional piped circuit construction. A manifold design using cartridges is more sophisticated than utilising VD4S units and greater attention is required in the assembly of the cartridges into the manifolds. Fast response and rapid frequency of operation even at the highest flow is achieved due to poppet design and precise ratio between its mass and stroke. The cast passages within the VD4S valve body when used with correctly designed manifolds ensure circuits in which pressure drop and oil turbulence is minimal. Veljan seat valves and cartridges function to direct flow from port A to port B or vice - versa and their operation is dependent upon the effective pressure area and spring force on the poppet. The cracking pressure is proportiona to the ratio of control area to seat or ring area. Pilot pressure at port X acting on the control area closes the seat valve, thus forces generated by cylinders or hydraulic motors can be decelerated to zero by controlling the differential pressure. Acceleration or deceleration of fluid which the seat valve is controlling will take place whilst the valve is opening or closing and the time normally necessary to overcome overlap in conventional spool valves is eliminated. In addition to this improved response time, the action also ensures that the seat valve functions without introducing system pressure peaks or shocks and therefore machine cycle times may be reduced without detriment. Various seat valve combinations are manufactured to suit a wide variety of specialized industrial applications. Cracking pressure depends on the area ratio of individua combination of spool and sleeve. together with spring Example : With a ratio of 95% seat area to 5% ring area and a spring pressure^ 2.2 barthen the following cracking pressures It is obvious that with flow direction B to A and a control (pilot pressure) at X of more than 15 bar, pressure in excess of maximum valve rating would be exceeded before the valve would open. Under static conditions the valve would stil remain leakproof even at substantially higher pressure.

Open the catalog to page 1

SEAT VALVES Control functions Typical functions which can be achieved in a circuit incorporating single or multiple seat valves Further control functions on request

Open the catalog to page 2

SEAT VALVES Body Type Series - VD4S Veljan Seat Valves are hydraulically operated poppet type cartridges designed to control flow direction either from port A to port B or vice versa depending upon the control circuit. The same modular design is used in all valve sizes and the valves and cartridges are used for a variety of - Either single or in a combination as a leak proof directional control. - As a pressure control for the adjustment of - As a check valve to obtain uni-directiona - As a throttle valve to control and limit the rate of The basic element incorporated in both the body...

Open the catalog to page 3

SEAT VALVES Body Type Series - VD4S Mounting position Ambient temperature Special working conditions Operating Pressure range Fluid Temperature Range Viscosity Range Oplimum operating viscosity Pilot volume - sleeve 95% seat area, spool 1 5° chamfer - sleeve 95% seat area, spool 45° chamfer - sleeve 60% seat area, spool 45° chamfer Type of control adjustment Nominal voltage Permissible Voltage difference Maximum coil temperature Input power Relative operating period Seat valve Threaded, Subplate and Flange mounteo Consult VELJAN 0 (Without pressure to tank) Electrically by solenoid (VVVOl )

Open the catalog to page 4

SEAT VALVES Body Type Series - VD4S ORDERING CODE Body mounting - ( 2 A Ports, 1 B Port ) X, Yi Port - /4" NPTF A- Threaded body - VD4S06 = 3/4 NPTF ; (1A Port, 1 BPort)X, Yi Port- V4 NPTF 6 - Threaded body - VD4S03 = V2' B.S.PP ; ( 2 A Ports, 1 B Port ) X,Yi Port - 1/ B.S.PP b - Threaded body - VD4S06 =3/4 B.S.PP ; (1 A Port, 1 B Port ) X,Yi Port -//B.S.PP ( 2 A - Ports, 1 B - Port ) X,Yi Port - V4" NPTF Pilot Oil Line - Body _ Subplate mounting Threaded body Subplate mounting & VW01 only Subplate mounting only Seal Class - Design letter Solenoid Voltage and current 09 - VW01 with manual...

Open the catalog to page 5

SEAT VALVES Body Type Series - VD4S RECOMMENDED SPRING, SPOOL, SLEEVE COMBINATIONS control function Pressure unloading control function Check valve Pressure control Pilot operated check valve Flow control function with throttle spool B (10°) ■ spool 1 & 2 : spring side pressure must not exceed pressure at A-port ■ spring as per requested cracking

Open the catalog to page 6

SEAT VALVES Body Type Series - VD4S ORDERING CODE EXAMPLES Subplate mounting Subplate mounting Threaded body Pilot oil Y = internal from B Subplate mounting Threaded body with vent valve VW01 Pilot oil X = internal from A Subplate mounting VD4S**-*A5-***- \® V With vent valve VW01 Pilot oil X = internal from A Drain Y = external to subplate Subplate mounting Threaded body With vent valve VW01 Subplate mounting With vent valve WV01 Drain Y = external to subplate

Open the catalog to page 7All Veljan Hydrair Limited catalogs and technical brochures

-

Hydraulic Filters

46 Pages

-

VT7QDCC

3 Pages

-

VR5V06 Series

8 Pages

-

VR5U08 Series

8 Pages

-

VR4R series

8 Pages

-

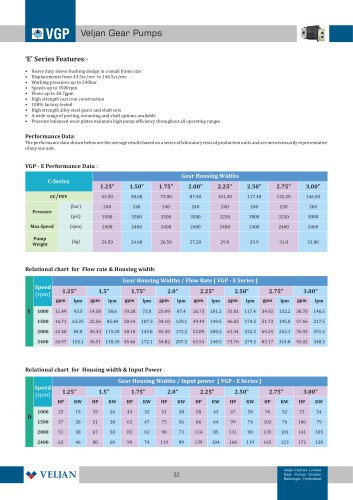

E Series

7 Pages

-

Gear Pump - D Series

7 Pages

-

Hydraulic Filters Catalogue

46 Pages

-

Gear Pump - C Series

7 Pages

-

Gear Pump - B Series

6 Pages

-

V4DO1

13 Pages

-

V4DO2

14 Pages

-

V4DO6

16 Pages

-

VR4V

8 Pages

-

VT7QDCB

3 Pages

-

VT6CC

2 Pages

-

VT7DSW

2 Pages

-

VTXB

3 Pages

-

VJ

13 Pages

-

VCC

6 Pages

-

VSD

6 Pages

-

VIC

7 Pages

-

ILV 750

7 Pages

-

ILV 725

7 Pages

-

ILV 720

9 Pages

-

ILV 714

9 Pages

-

Hydraulic Cylinders

23 Pages

-

VVV01

2 Pages

-

System Saver - Single Vane Pump

17 Pages

-

VT67EDC

3 Pages

-

VT67DDCS

3 Pages

-

VT67DCC

3 Pages

-

VT67EC

2 Pages

-

VT67BB

2 Pages

-

VT6CB

3 Pages

-

VT6BB

4 Pages

-

VTXBB

4 Pages

-

VD4S06

14 Pages

-

VDRV7 - VDV7 06 ? 08

6 Pages

-

VR5S06

8 Pages

-

VR4S03

8 Pages

-

VR4U10

9 Pages

-

VR5V12

8 Pages

-

VRIEO2

5 Pages

-

VT7EE/VT7EES

2 Pages

-

VT6EDCR

3 Pages

-

VT6DCCR

3 Pages

-

VT6CRM

2 Pages

-

VT6CR

2 Pages

-

J9V045

15 Pages

-

J9V009

7 Pages

-

VM4E

2 Pages

-

VM4D

2 Pages

-

VM4C

2 Pages

-

VM3B

2 Pages

-

System Saver

17 Pages

Archived catalogs

-

VELJAN HYDRAULIC PRODUCTS

11 Pages