Catalog excerpts

VEUAN model V4D02 direct operated Directional Control valves conform to NFPA D05, NG 10 (CETOP 05) standard interface. These are subplate and manifold mounted and can be used in conjunction with stack valve system. The valve mounting interface and electrical connection methods conform to international standards CETOP, ISO, DIN. The coils used in the wet pin design solenoids are available in A.C. and D.C. voltages and are continuously rated. Precise guide for all types of spools is achieved by uniquely designed five annuli body. Spools are interchangeable and no selective assembly is necessary. ♦ Extremely low pressure drop at high flow rates due to optimised flow paths in body & spool design. ♦ Compact five annuli body design. ♦ Mounting configuration according to CETOP R35H, ISO 4401 and DIN 24340 ♦ Wide variety of spool types including detent. ♦ Interchangeability of spools & bodies due to high precision manufacturing processes. ♦ Actuated by electrical / hydraulic / pneumatic / cam or lever mechanism. ♦ Wide range of A.C. and D.C. coil voltages are available both with or without manual override. ♦ Low electrical power consumption (48 W) ♦ Change of solenoid coil is fast and simple without risk of oil leakage. ♦ Solenoid coil can be positioned at 90° intervals with respect to body . ♦ Electrical connection by standard 3 pin connector according to DIN 43650, ♦ Optional plug-in connector with LED display are available. ♦ Soft shifting version by use of an orifice is optional. ♦ Every valve is factory tested pr

Open the catalog to page 1

OPERATION & CHARACTERISTICS The Directional Control valve 4D02 consists of a body, spool and either one or two actuators depending upon the application. The spool is shifted by the action of electrical solenoid, mechanical, hydraulic, pneumatic, cam or lever actuator mechanism. Spool movement allows oil under pressure from port P to flow to either port A or B, and subsequently connect the other port to tank. On de-energizing the actuator, the spool is returned to the center position or offset position. Manual operation of spool is possible using the optional manual override system....

Open the catalog to page 2

SOLENOID CHARACTERISTICS PRESSURE DROP Solenoid Characteristics

Open the catalog to page 3

Spring Centered Spring Offset j*jp§ Transfer position only.

Open the catalog to page 4

ORDERING CODE D = Soft shift Option G3 with DC-solenoid operation with AC & DC solenoid operation D = Pneumatic operation, one-sided E = Pneumatic operation, both sides F = Pneumatic operation, both sides Spool Type -' Spool Position - 07=3 pos. detents (for control 4 only) _Valve Accessories / 32 = Tube cartridge without manual override 52 = tube cartridge with manual override and rubber cover C9 = 24 V DC Solenoid coil with 36 W G3 = Soft shift version with 0.8 mm orifice in channel-Z (only body type D with DC). -Solenoid Voltage -Seal Class -Design Letter 05 = for control 4 & spool...

Open the catalog to page 5

FUNCTIONAL LIMITS Valve with DC Solenoid (s) If the performance characteristics outlined above do not meet your particular requirements, please contact your local Veljan office.

Open the catalog to page 6

LEVER OPERATED VERSION

Open the catalog to page 11

SOFT SHIFT VERSION, OPTION G3 VEUAN make CETOP 5 soft shift version (option G3) has special solenoids that permit a multiple increase of standard spool response time. • Reduced pressure shocks in venting operations. • Reduced system noise during spool transition. • Increased lifetime of the valve and system. With body option "D" and "Soft Shift", the flow rating of the valve is reduced by approximately 25 of the nominal value. Ensure that channel Z is filled with oil at all times. For this the valve is equipped with venting screws. Valve to be properly vented during initial installation and...

Open the catalog to page 13

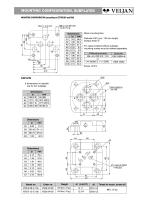

MOUNTING CONFIGURATION, SUBPLATES L^^TJMW^l?] MOUNTING CONFIGURATION (according to CETOP.ISO and DIN)

Open the catalog to page 14All Veljan Hydrair Limited catalogs and technical brochures

-

Hydraulic Filters

46 Pages

-

VT7QDCC

3 Pages

-

VR5V06 Series

8 Pages

-

VR5U08 Series

8 Pages

-

VR4R series

8 Pages

-

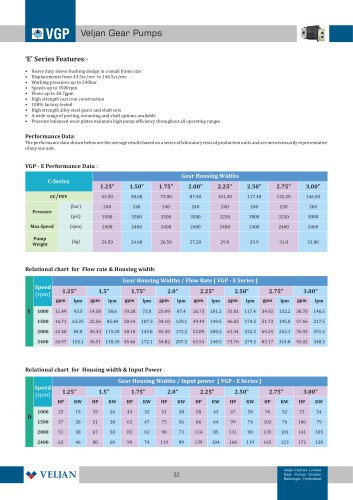

E Series

7 Pages

-

Gear Pump - D Series

7 Pages

-

Hydraulic Filters Catalogue

46 Pages

-

Gear Pump - C Series

7 Pages

-

Gear Pump - B Series

6 Pages

-

V4DO1

13 Pages

-

V4DO6

16 Pages

-

VR4V

8 Pages

-

VT7QDCB

3 Pages

-

VT6CC

2 Pages

-

VT7DSW

2 Pages

-

VTXB

3 Pages

-

VJ

13 Pages

-

VCC

6 Pages

-

VSD

6 Pages

-

VIC

7 Pages

-

ILV 750

7 Pages

-

ILV 725

7 Pages

-

ILV 720

9 Pages

-

ILV 714

9 Pages

-

Hydraulic Cylinders

23 Pages

-

VVV01

2 Pages

-

System Saver - Single Vane Pump

17 Pages

-

VT67EDC

3 Pages

-

VT67DDCS

3 Pages

-

VT67DCC

3 Pages

-

VT67EC

2 Pages

-

VT67BB

2 Pages

-

VT6CB

3 Pages

-

VT6BB

4 Pages

-

VTXBB

4 Pages

-

VD4S06

14 Pages

-

VD4S03

12 Pages

-

VDRV7 - VDV7 06 ? 08

6 Pages

-

VR5S06

8 Pages

-

VR4S03

8 Pages

-

VR4U10

9 Pages

-

VR5V12

8 Pages

-

VRIEO2

5 Pages

-

VT7EE/VT7EES

2 Pages

-

VT6EDCR

3 Pages

-

VT6DCCR

3 Pages

-

VT6CRM

2 Pages

-

VT6CR

2 Pages

-

J9V045

15 Pages

-

J9V009

7 Pages

-

VM4E

2 Pages

-

VM4D

2 Pages

-

VM4C

2 Pages

-

VM3B

2 Pages

-

System Saver

17 Pages

Archived catalogs

-

VELJAN HYDRAULIC PRODUCTS

11 Pages