Catalog excerpts

VEUAN model V4D01 direct operated Directional Control valves conform to NFPA D03, NG 6 (CETOP 03) standard interface. These are subplate and manifold mounted and can be used in conjunction with stack valve system. The valve mounting interface and electrical connection methods conform to international standards CETOP, ISO, DIN. The coils used in the wet pin design solenoids are available in A.C. and D.C. voltages and are continuously rated. Precise guide for all types of spools are achieved by uniquely designed five annuli body. Spools are interchangeable and no selective assembly is necessary. ♦ Low pressure drop for reduced heat loss and increased efficiency. ♦ Compact five annuli body design. ♦ Mounting configuration according to CETOP R35H, ISO 4401 and DIN 24340 ♦ Wide variety of spool types including detent, and interchangeable spools and bodies. ♦ Actuated by electrical / hydraulic / pneumatic / cam or lever mechanism. ♦ Wide range of A.C. and D.C. coil voltages are available both with or without manual override. ♦ Low electrical power consumption (29 W / 24 V DC) ♦ Quick change of solenoid coil without risk of oil leakage. ♦ Solenoid coil can be positioned at 90° intervals with respect to body . ♦ Upto 210 bar pressure allowable at tank port. ♦ Electrical connection by standard 3 pin connector according to DIN 43650 , ISO 4400 or ♦ Optional plug-in connector with LED display are available. ♦ Every valve is factory tested prio

Open the catalog to page 1

OPERATION CHARACTERISTICS The Directional Control valve V4D01 consists of a body, spool and either one or two actuators depending upon the application. The spool is shifted by the action of electrical solenoid, mechanical, hydraulic, pneumatic, cam or lever actuator mechanism. Spool movement allows oil under pressure from port P to flow to either port A or B, and subsequently connect the other port to tank. On de-energizing the actuator, the spool is returned to the center position or offset position. Manual operation of spool is possible using the optional manual override system....

Open the catalog to page 2

SOLENOID CHARACTERISTICS PRESSURE DROP Solenoid Characteristics Nominal Voltage Power Input Holding Power Inrush Power Permissible Voltage difference Maximum coil temperature Relative Operating Period Insulation Class Pressure Drop Performance data given is typical and can be influenced by application.

Open the catalog to page 3

Spring Centered Spring Offset * Standard Spools * Spool Position 01 only ** Spool Position 02 only

Open the catalog to page 4

ORDERING CODE H= Bottom connection for Hyd. Operation D = Pneumatic operation, one-sided E = Pneumatic operation, both sides * F = Pneumatic operation, both sides Q = Hydraulic operation, one-sided R = Hydraulic operation, both sides * S = Hydraulic operation, both sides Spool Type Spool Position - 07=3 pos. detents (for control 4 only) Valve Accessories / Plug-in connector Wiring box and flying leads manual override and orifice Harrison Connector Plug-in connector, manual over-ride and indicator lamps rubber cover Wiring Box with indicator lamps and Brad Harrison Wiring Box and flying...

Open the catalog to page 5

FUNCTIONAL LIMITS Valve with Standard DC-solenoid 0 Curves for spool with detents 1) Only if port A and B is closed

Open the catalog to page 6

1-AND 2-SOLENOID AC/DC OPERATED VERSIONS Single solenoid Double solenoid Manual override- manual over

Open the catalog to page 7

1-AND 2-SOLENOID AC/DC OPERATED VERSIONS Single solenoid Double Solenoid Manual Override Rubber cover Port Functions:

Open the catalog to page 8

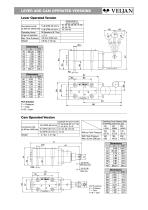

LEVER AND CAM OPERATED VERSIONS Lever Operated Version

Open the catalog to page 9

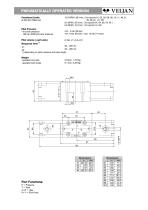

PNEUMATICALLY OPERATED VERSION Functional Limits Pilot Pressure Pilot volume (each side) 1) depending on pilot pressure and pipe length -operated both sides |<»>| VlfLIANl

Open the catalog to page 10

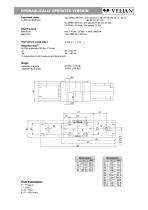

HYDRAULICALLY OPERATED VERSION Functional Limits Pilot Pressure Pilot volume (each side) 1) depending on pilot pressure and pipe length -operated both sides |<*>| vyjMfl VELJAN HYDtAIRPV

Open the catalog to page 11

SOFT SHIFT VERSION, OPTION G3 VEUAN make CETOP 3 soft shift version (option G3) has special solenoids that permit a multiple increase of solenoid response time. - Reduced pressure shocks in venting operations. - Reduced system noise during spool transition. - Increased lifetime of the valve and system. Circuit Design Example pressure unloading P to A: Pressure shift sequence of spool stroke o to a or o to b. 1. The functional limit of soft shift version will be reduced by as much as 25 from standard, depending on the spool type. 2. The solenoid tube cartridges must remain filled with oil at...

Open the catalog to page 12

MOUNTING CONFIGURATION, SUBPLATES MOUNTING CONFIGURATION (according to CETOP, ISO and DIN)

Open the catalog to page 13All Veljan Hydrair Limited catalogs and technical brochures

-

Hydraulic Filters

46 Pages

-

VT7QDCC

3 Pages

-

VR5V06 Series

8 Pages

-

VR5U08 Series

8 Pages

-

VR4R series

8 Pages

-

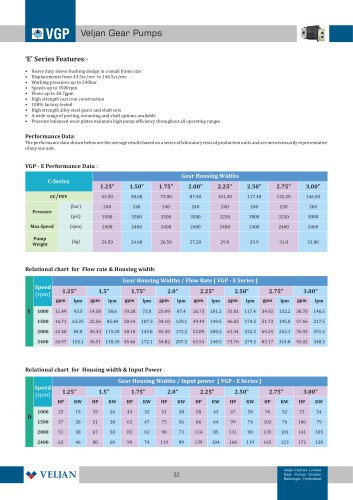

E Series

7 Pages

-

Gear Pump - D Series

7 Pages

-

Hydraulic Filters Catalogue

46 Pages

-

Gear Pump - C Series

7 Pages

-

Gear Pump - B Series

6 Pages

-

V4DO2

14 Pages

-

V4DO6

16 Pages

-

VR4V

8 Pages

-

VT7QDCB

3 Pages

-

VT6CC

2 Pages

-

VT7DSW

2 Pages

-

VTXB

3 Pages

-

VJ

13 Pages

-

VCC

6 Pages

-

VSD

6 Pages

-

VIC

7 Pages

-

ILV 750

7 Pages

-

ILV 725

7 Pages

-

ILV 720

9 Pages

-

ILV 714

9 Pages

-

Hydraulic Cylinders

23 Pages

-

VVV01

2 Pages

-

System Saver - Single Vane Pump

17 Pages

-

VT67EDC

3 Pages

-

VT67DDCS

3 Pages

-

VT67DCC

3 Pages

-

VT67EC

2 Pages

-

VT67BB

2 Pages

-

VT6CB

3 Pages

-

VT6BB

4 Pages

-

VTXBB

4 Pages

-

VD4S06

14 Pages

-

VD4S03

12 Pages

-

VDRV7 - VDV7 06 ? 08

6 Pages

-

VR5S06

8 Pages

-

VR4S03

8 Pages

-

VR4U10

9 Pages

-

VR5V12

8 Pages

-

VRIEO2

5 Pages

-

VT7EE/VT7EES

2 Pages

-

VT6EDCR

3 Pages

-

VT6DCCR

3 Pages

-

VT6CRM

2 Pages

-

VT6CR

2 Pages

-

J9V045

15 Pages

-

J9V009

7 Pages

-

VM4E

2 Pages

-

VM4D

2 Pages

-

VM4C

2 Pages

-

VM3B

2 Pages

-

System Saver

17 Pages

Archived catalogs

-

VELJAN HYDRAULIC PRODUCTS

11 Pages