Catalog excerpts

Veljan's reputation as the designer and manufacturer of fluid power products of utmost reliable quality is an established fact for over 35 years now. With the back-up of up-to-date & state-of-the-art production facilities and a clear-cut focus on design engineering and product development, Veljan effectively meets the demand for a very wide spectrum of applications, such as in : ♦ STEEL MILL EQUIPMENT ♦ ATOMIC ENERGY EQUIPMENT ♦ POWER PROJECTS EQUIPMENT ♦ STABILISERS AND STEERING GEARS ♦ FORGE AND FOUNDRY EQUIPMENT Besides hydraulic and pneumatic cylinders for every conceivable application, Veljan continues to engineer, manufacture and market a wide range of pneumatic products. To achieve, maintain and provide a "single source system" facility, Veljan's joint venture company manufactures high performance Hydraulic Pumps, Motors, Valves and Systems. This has enabled Veljan products and services to be reckoned as the benchmarks for quality. While this catalogue is intended as a brief guide to the selection of standard Veljan Hydraulic Cylinders, Veljan also offers customised equipment and the specials needed by its valued and satisfied customers drawn from various sectors of the industry who have been regularly sourcing their requirements of these cylinders and other fluid power products from Veljan. Veljan, with its proven track record, technical expertise, design and engineering capabilities in the realm of high quality products and prompt services is confident of satisfying the exacting

Open the catalog to page 1

HYDRAULIC TYPES OF HYDRAULIC CYLINDERS Veljan offers various types of Hydraulic Cylinders for different pressure ratings and applications : Series-HT Compact tie-rod square type construction Hydraulic Cylinders rated for 160 bar with mounting dimensions conforming to ISO:6020 part 2 for 40 to 200 mm bore and ISO:6020 part 3 for 250 and 320 mm bore sizes. Series-HR Non-tie-rod welded round type construction of 160 bar medium series Hydraulic Cylinders with mounting dimensions conforming to ISO:6020 - part 1, in bore sizes from 40 to 320 mm. The above HT and HR series cylinders are also...

Open the catalog to page 2

SEALS offers differ ferent Veljan offers the following variety of seals to suit different applications : PISTON SEALS ROD SEALS ELASTOMERIC Piston seals with integral anti-extrusion Rings are fitted as a standard for 160 bar application.Compact seals with bearing rings conforming to ISO:6547 dimensions and leak-tight under normal operating conditions are optional. These are suitable for speeds upto 0.5 m/s and holding loads in position. POLYURETHANE internally lubricated Rod Seals LOW FRICTION Piston Seals conforming to ISO:7425-1 grooves employ an elastomer energised PTFE ring and may be...

Open the catalog to page 3

ELASTOMERIC PISTON SEAL POLYURETHANE LOW FRICTION PISTON SEAL PTFE ROD SEAL LOW FRICTION ROD SEAL PTFE CAST IRON PISTON RINGS 7 SEAL ROD U-CUPS WIPER

Open the catalog to page 4

HOW TO SELECT A VELJAN CYLINDER : APPLICATION ENGINEERING The following simple steps ensure that principal factors are considered while selecting the cylinder : Application 1. First Establish : -Force (F) needed or weight to be moved -Stroke or distance to be travelled. Check the following Acceleration Check whether the calculated and force is sufficient to accelerate/ Decelaration decelerate the load within prescribed distance. Check back-pressure rise during cushioning is within limits. 2. Based on the available or selected system pressure P, calculate the cylinder areas required by using...

Open the catalog to page 5

ACCELERATON ACCELERA TON & DECELERATION DECELERATION IN CYLINDERS : It is often necessary to determine the Force F required to accelerate or decelerate a given mass. The maximum velocity `V’ attained by a mass `m’ over a distance `s’ is dependant on the force `F’ related as 2 follows : F=ma where a= v 2S These forces will help in selecting a proper size cylinder, pump pressure etc. They will also help in checking the safety of various system components by finding out the pressure rise when a moving load is stopped by means of internal cushions. The following examples well help in...

Open the catalog to page 6

CUSHIONING In power cylinders, cushioning means deceleration of moving masses. Cushioning extends cylinder life and reduces undesirable noise and hydraulic shock. 1. When Cushions are required. Cushioned cylinders should be used whenever the piston is required to move heavy loads or travel at high speeds, say more than 0.1m/sec. Under both these conditions, the piston will pound the head and cap causing heavy damage to the piston and also heavy deceleration forces will be set up on the moving members. To minimise these effects, a back pressure or resisting force must be built up inside the...

Open the catalog to page 7

FEATURES OPTIONAL FEATURES AIR BLEEDS Hydraulic cylinders vertically mounted or horizontally mounted with ports on top are self bleeding when cycled full stroke and do not require air bleeds. When required or called for, bleed screws can be optionally provided at either end of the cylinder. Location of bleed screws must be specified to suit the accessibility in a particular application. The bleeder port of 1 /4” BSP is standardized for cylinders of 50mm bore and above. 1/8” BSP is provided for 40mm bore cylinders. Minimess type bleed screws are optional. AIR BLEEDS STANDARD TYPE MINIMESS...

Open the catalog to page 8

STOP TUBING Stop tube is ideal for preventing excessive bearing wear and rod buckling on long push stroke cylinders. A stop tube is a tubular spacer positioned between the piston and the cylinder head in the extended condition. The increased distance between the piston and the Rod bushing reduces bearing reactions. Stop tubes are useful to prevent buckling of horizontally mounted, long stroke cylinders on push stroke. These are more effective, less costly, and lighter in weight than oversize piston rods. When to specify stop tubing for your cylinder. The following simple steps give you the...

Open the catalog to page 9

STOP TUBE GROUP A STOP TUBE IS NOT REQUIRED. TO CHECK FOR ROD DIAMETER SHORT GUIDE LONG GUIDE LOAD PIN - CONNECTED & GUIDED LOAD SUPPORTED & GUIDED ANY FIXED/MIXED MOUNTING (HORIZONTAL/VERTICAL) GROUP B VERTICAL MOUNTINGS GROUP C HORIZONTAL MOUNTINGS

Open the catalog to page 10All Veljan Hydrair Limited catalogs and technical brochures

-

Hydraulic Filters

46 Pages

-

VT7QDCC

3 Pages

-

VR5V06 Series

8 Pages

-

VR5U08 Series

8 Pages

-

VR4R series

8 Pages

-

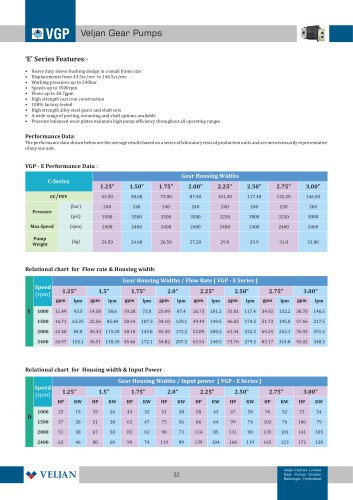

E Series

7 Pages

-

Gear Pump - D Series

7 Pages

-

Hydraulic Filters Catalogue

46 Pages

-

Gear Pump - C Series

7 Pages

-

Gear Pump - B Series

6 Pages

-

V4DO1

13 Pages

-

V4DO2

14 Pages

-

V4DO6

16 Pages

-

VR4V

8 Pages

-

VT7QDCB

3 Pages

-

VT6CC

2 Pages

-

VT7DSW

2 Pages

-

VTXB

3 Pages

-

VJ

13 Pages

-

VCC

6 Pages

-

VSD

6 Pages

-

VIC

7 Pages

-

ILV 750

7 Pages

-

ILV 725

7 Pages

-

ILV 720

9 Pages

-

ILV 714

9 Pages

-

VVV01

2 Pages

-

System Saver - Single Vane Pump

17 Pages

-

VT67EDC

3 Pages

-

VT67DDCS

3 Pages

-

VT67DCC

3 Pages

-

VT67EC

2 Pages

-

VT67BB

2 Pages

-

VT6CB

3 Pages

-

VT6BB

4 Pages

-

VTXBB

4 Pages

-

VD4S06

14 Pages

-

VD4S03

12 Pages

-

VDRV7 - VDV7 06 ? 08

6 Pages

-

VR5S06

8 Pages

-

VR4S03

8 Pages

-

VR4U10

9 Pages

-

VR5V12

8 Pages

-

VRIEO2

5 Pages

-

VT7EE/VT7EES

2 Pages

-

VT6EDCR

3 Pages

-

VT6DCCR

3 Pages

-

VT6CRM

2 Pages

-

VT6CR

2 Pages

-

J9V045

15 Pages

-

J9V009

7 Pages

-

VM4E

2 Pages

-

VM4D

2 Pages

-

VM4C

2 Pages

-

VM3B

2 Pages

-

System Saver

17 Pages

Archived catalogs

-

VELJAN HYDRAULIC PRODUCTS

11 Pages