Catalog excerpts

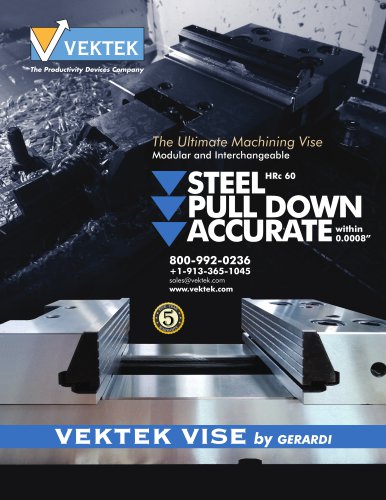

Most expensive CNC met al work ing ma chines are purchased without fixtures to hold the workpiece(s). With todayΒs so phis ti cat ed ma chines making tool changes in frac tions of a second and cutting at speeds we once thought nearly impossible, the speed and quality of part clamping is the next most important opportunity for time savings and pro duc tiv i ty im prove ment. VektorFlo Hardened and Chromed bearing sur faces are in cor po rated to provide improved load bearing areas where it is critical to device life. > Our unique blend of telemarketing, catalog and technical support is there...

Open the catalog to page 4

Successful powered workholding does not just happen. Like any other manu fac tur ing process, it must be carefully planned. But that does not mean that you need to be a hy drau lics engineer to implement a powered work hold ing system. Designing a system involves nothing more than the common-sense ap pli ca tion of a few basic work hold ing concepts.Applications for power workholding fall into two categories: retrofits to replace and upgrade clamping on existing fixtures; and new fixtures designed from the outset with power workholding. In both cases it is im pera tive that you keep in mind...

Open the catalog to page 5

First, determine the nature of the op era tion to be performed, the number of parts to be processed per cycle, and whether operations will be performed on more than one surface of each part. Also determine the time that should be allowed for part loading, un load ing, and clamp ing.Consult your machine tool file to de ter mine the available work space on the machine table, bed, chuck or other sur face, as applicable. Be sure that the space avail able will accommodate the part or quantity of parts to be proc essed ac cord ing to your man u fac tur ing work-flow. If not, revise your plan.In...

Open the catalog to page 6

The expression .01 x (sys. op. press. 1000) takes into account the slight com press ibil i ty of oil and system elasticity which influence the length of time required to pressurize a system. Pressurize time is the total time to reach pressure ex pressed in decimal parts of a minute.If total estimated clamping time is not within the cycle time requirements youve targeted but is within device limitations, a larger power source is required 璗 one with greater capacity. Select such a source and repeat the above cal cu la tions to ensure that it will provide the clamping cycle times required. If...

Open the catalog to page 7

My pump runs continuously. Is it the right type of pump? Is my pump of appropriate size? It is rated for _____gpm, or _____cu. in. per minute. My devices require a total of _____cu. in. of oil to actuate. For most normal size fixtures, a pump rated in gpm (gallons per minute) is not recommended. If your pump is rated much more than 1 gpm, call us, wed rather give you sound advice now than have you damage clamps and have to sell you replacements. Be sure that you do not exceed the recommended flow rates for your system. If you arenҒt sure, ask us. Call us. It can often be made to work. Some...

Open the catalog to page 9

When I look at my clamps, there are threaded holes in them. What do the labels PӔ ADVANCEӔ RETRACTӔ mean? These threaded holes are called portsӔ. The label PӔ or ADVANCEӔ ports are normally used to clamp the part, RETRACTӔ indicates the port normally used to unclamp or retract the clamp. My local chemical representative has rec om-mend ed the use of wa ter-glycolӔ hydraulic fluid. What are the benefits of this fluid and should I use it? Water-glycol is a nontraditional hydraulic fluid. This fluid was de vel oped for use where pe tro leum based fluids are not allowed. They are commonly used...

Open the catalog to page 10

If you have questions youd like answered, call, write, fax or email us. We would be glad to help you use VektorFlo I need a clamp just like your 15-0109-08 except it needs a 6Ҕ long rod. Can you help me? Maybe. We do entertain specials from time to time. Please ask us. We often find that specialӔ requests coincide with our ongoing new product development. If you have a special need, it is worth asking. We may decide to do your special as a de vel op ment project. We may not be able to produce it (actually you may not want it) because of cost. It may be some thing we have done before and...

Open the catalog to page 11

Do I need to use a torque wrench and socket when installing cartridge work supports? Yes, a torque wrench and a 6 point socket is required. If you use an open end, adjustable or box end wrench you increase the chances of damaging the thread, roundness of the support sleeve or damaging the seals causing leakage between the sleeve and body. Please use an appropriate socket, torque wrench and care when installing cartridge work supports. You are correct that the impact of the re-entry of the cutter to the next web of your part will create an interruption and the mass of your straddle mill may...

Open the catalog to page 14

Highly repeatable, repeats position plus or minus 0.0002 in. Built in polyurethane wipers keep chips and debris out and reduces the chance of plunger/ sleeve sticking or binding. > work supports last longer and stand up to harsh en vi ron ments and abuse bet ter than models without these features.Proprietary wiper and seal de signs reduce con tam i na tion and drag for longer lasting, better per form ing work sup ports. Special corrosion resistant plungers and sleeves reduce the tendency to stick. Coating on the cylinder bodies helps prevent corrosion.Special large diameter plungers and...

Open the catalog to page 15

Cartridge Mount Cavity Dimensions > VEKTEK, INC. 1-800-992-0236 > Vektek, Inc. April 2007 size="-2">

Open the catalog to page 22

Frequently Asked Questions > When do you recommend the use of high-speed swing clamps over the standard product? Im using a high volume pump and it is ғblowing out my swing clamps. Will high-speed swing clamps take care of this problem? > Sometimes there are applications where speed is essential, massive arms are required, or position sensing and feedback are necessary. These applica- tions may result in premature failure not due to defects in standard clamps, but from excesses in speed, mass or other requirements. When speed is essential, standard swing clamps (which last millions of...

Open the catalog to page 24All Vektek catalogs and technical brochures

-

Accessory Valves

1 Pages

Archived catalogs

-

VektorAir

36 Pages

-

VektorFlo Metric

108 Pages