Catalog excerpts

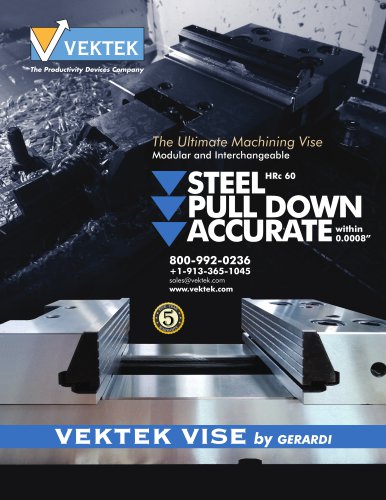

The Ultimate Machining Vise Modular and Interchangeable STEEL PULL DOWN ACCURATE HRc 60 VEKTEK VISE by GERARDI

Open the catalog to page 1

Standard Vise Precision Modular Vises Series The most popular! • All steel construction hardened and ground HRc 60 • Accuracy within 0.0008" • Geometrically toleranced surfaces and locators make initial setup and gang operation easy. • Pull down jaws help hold the part against the vise base while clamping and can be locked in the down position if pull down action is not needed. • Space saving shorter vise base frees several inches of “Z” travel for parts and spindle. • No wear (5 year warranty) • Long bases are available to hold larger parts, up to 20” or more. The jaw carrier is normally...

Open the catalog to page 2

H (B minus desired Step Height = H) 5 X 5 (10 X 5 for Type 5) VEKTEK VISE by GERARDI W Standard precision modular vise with standard equipment Clamp Force Vise Type Dimensions are shown in millimeters, inch dimension conversions (X”) are for reference and comparison purposes. Screw Travel Weight Magnetic Parallel Plates - FOR CUSTOM Specify Step Height H (mm) H = (mm) Model No. Intermediate Movable Jaw - FOR CUSTOM Specify Step Height H (mm) H H To be used with magnetic parallel plates H = (mm) Model No. Order Step Offset to Size When ordering the above accessories, select the standard H...

Open the catalog to page 3

Flex Vise Innovative quick change jaw guide system for pull-down jaws Same as Standard, PLUS... • Vertical operation as a 2 sided tower on horizontal machines. • Quick change jaws with comb guiding feature for easy changes. • Great savings in vise resetting times and jaw changes. • More effective protection from chips. • Increased and more precise guided pull down action. • Highest repositioning accuracy. NO WEAR QUICK CLAMPING MODULARITY & VERSATILITY CHANGE JAWS IN SECONDS HIGHEST ACCURACIES 0.0008” RIGIDITY & SAFETY SPACE SAVING DESIGN 1 HIGHEST REPOSITIONING ACCURACY CUTS SETUP TIME...

Open the catalog to page 4

H (B minus desired Step Height = H) VEKTEK VISE by GERARDI Vise Type Clamp Force Dimensions are shown in millimeters, inch dimension conversions (X”) are for reference and comparison purposes. Jaw Width W Base Length D G Screw Travel Magnetic Parallel Plates - FOR CUSTOM Specify Step Height H (mm) H When ordering the above H accessories, select the 3 H1 standard H desired and specify after Model No. To receive other than H standard offset, specify your desired H dimension after Model No. Dimensions B minus desired Step Offset = H to order Intermediate Movable Jaw - FOR CUSTOM Specify Step...

Open the catalog to page 5

Easy jaw positioning This detailed illustration shows the gross adjustment locking mechanical support that holds the movable vise jaw security in position. The fine adjustment and clamping is driven by the clamping bolt. Flex vise illustrated with position locator plug installed. VISE NUMBER Actual KITS may vary from illustrations depending upon the model selected. NON-REPLACEMENT PART

Open the catalog to page 6

Add HYDRAULIC POWER to ANY Vektek Vise It’s easy to add hydraulic power to the Vektek Vise by simply replacing the mechanical clamping support with a hydraulic clamping support. The single acting hydraulic cylinder will require a hydraulic power source, operational control and some plumbing, easily purchased from Vektek. Multiple vises can be arranged to hold large or multiple parts for machining. KIT 1 contact Team Vektek: 800-992-0236 sales@vektek.com Vise Type Model Number Cylinder stroke Flex Vise VISE NUMBER NON-REPLACEMENT PART Actual KITS may vary from illustrations depending upon...

Open the catalog to page 7

VEKTEK LLC 1334 E 6th Avenue Emporia, KS 66801 www.vektek.com The Ultimate Machining Vise VEKTEK VISE by GERARDI Revised March 2021

Open the catalog to page 8All Vektek catalogs and technical brochures

-

Accessory Valves

1 Pages

Archived catalogs

-

VektorAir

36 Pages

-

Vektorflo

168 Pages

-

VektorFlo Metric

108 Pages