Website:

VEGA TECHNIQUE

Website:

VEGA TECHNIQUE

Group: VEGA Grieshaber KG

Catalog excerpts

Product information Guided Wave Radar Level and interface measurement in liquids VEGAFLEX 81 VEGAFLEX 83 VEGAFLEX 86

Open the catalog to page 1

Please note the Ex specific safety information that you can find at www.vega.com and that comes with each instrument. In hazardous areas you should take note of the appropriate regulations, conformity and type approval certificates of the sensors and power supply units. The sensors must only be operated on intrinsically safe circuits. The permissible electrical values are stated in the certificate. Guided Wave Radar - Level and interface measurement in liquids Take note of safety instructions for Ex appli

Open the catalog to page 2

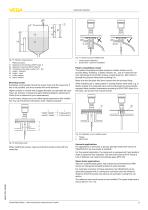

Measuring principle 1 Measuring principle Measuring principle High frequency microwave pulses are coupled onto a cable or rod and guided along the probe. The pulse is reflected by the product surface. The time from emission to reception of the signals is proportional to the distance of the level. The instrument is supplied with the probe length (0 % and 100 %) already adjusted. In most cases setup on site is not required. In any case, you set up VEGAFLEX without medium. The shortenable, bare cable and rod versions can be simply adapted to the local requirements, if necessary. Level...

Open the catalog to page 3

Measuring principle Reference plane Distance to the interface (HART value 1 or Primary Value) Distance to the level (HART value 3 or Third Value) Thickness of the upper medium (d1 - d2) Height - Interface Height - Level Lower medium Upper medium Guided Wave Radar - Level and interface measurement in liquids

Open the catalog to page 4

Type overview 2 Type overview VEGAFLEX 81 Cable version Coax version Storage tanks, liquids with agitated surface Storage tanks, liquids with smooth surface Storage tanks, liquids with low dielectric constant, vessel with installations Cable probe Coax probe Process fitting Process temperature Process pressure Measuring accuracy Signal output 4 … 20 mA/HART - two-wire 4 … 20 mA/HART - four-wire Profibus PA Foundation Fieldbus Modbus and Levelmaster protocol PLICSCOM PACTware VEGADIS 81 VEGADIS 62 ATEX IEC Shipbuil

Open the catalog to page 5

Type overview Cable version Aggressive and corrosive liquids Aggressive and corrosive liquids Hygienic applications in the food processing and pharmaceutical industry Cable probe Polished version (Basle Standard) Process fitting/Material Hygienic fittings Hygienic fittings Hygienic fittings Process temperature Process pressure Signal output 4 … 20 mA/HART - two-wire 4 … 20 mA/HART - four-wire Profibus PA Foundation Fieldbus Modbus and Levelmaster protocol PLICSCOM PACTware VEGADIS 81 VEGADIS 6

Open the catalog to page 6

Type overview Cable version Coax version High temperature applications High temperature applications High temperature applications Cable probe Coax probe Process fitting Process temperature Process pressure Signal output 4 … 20 mA/HART - two-wire 4 … 20 mA/HART - four-wire Profibus PA Foundation Fieldbus Modbus and Levelmaster protocol PLICSCOM PACTware VEGADIS 81 VEGADIS 62 ATEX IEC Shipbuilding Overfil

Open the catalog to page 7

Instrument selection 3 Instrument selection Application areas VEGAFLEX 81 VEGAFLEX 81 is suitable for applications with liquids in small vessels under ordinary process conditions. There are application possibilities in nearly all areas of industry. Through a large selection of gravity weights, the VEGAFLEX 81 can be also used in standpipes and bypass tubes. The PFA-coated VEGAFLEX 83 is suitable for measurement in aggressive liquids or applications with special hygienic requirements. Application possibilities can be found in the chemical industry as well as in the food processing and...

Open the catalog to page 8

Instrument selection Fig. 17: Socket must be installed flush Reference plane Distance to the interface (HART value 1) Distance to the level (HART value 3) Thickness of the upper medium (d1 - d2) Height - Interface Height - Level Lower medium Upper medium Unfavourable installation Socket flush - optimum installation Plastic vessel/Glass vessel The guided microwave principle requires a metallic surface on the process fitting. Therefore, in plastic vessels, etc., use an instrument version with flange (from DN 50) or place a metal sheet (ø > 200 mm/8 in) beneath the process fitting when...

Open the catalog to page 9

Instrument selection Reference plane Probe length (L) Measuring range Upper dead band Lower dead band Additional upper dead band by steam compensation Reference measurement distance to steam compensation Groove nut Process fitting Cover with groove nut Autoclaved version For use in an autoclave, e.g. for sterilization, the polished version of VEGAFLEX is available as autoclavable version. Hence you can separate the housing from the process fitting. The side of the process fitting is provided with a cover after the housing is removed. After autoclaving, attach the housing again and the...

Open the catalog to page 10

Selection criteria 4 Selection criteria VEGAFLEX 81 Non-metallic vessels Measurement in a standpipe or bypass tube Aggressive liquids Bubble or foam generation Wave movements at the surface Changing density Ammonia application Hygienic applications Narrow space above the vessel Steam boiler application Threaded fittings Flange connections Process fitting Hygienic fittings Probe Stainless steel Polished (Basel Standard) Power generation

Open the catalog to page 11

Housing overview 5 Housing overview Plastic PBT Protection rating Single chamber Double chamber Application area Industrial environment Industrial environment Aluminium Protection rating Version Single chamber Double chamber Application area Industrial environment with increased mechanical stress Industrial environment with increased mechanical stress Stainless steel 316L Protection rating Single chamber, electropolished Single chamber, precision casting Double chamber, precision casting Application area Aggressive environment, food processing, pharmaceutical Aggressive environment, extreme...

Open the catalog to page 12

6 Mounting Mounting examples The following illustrations show mounting examples and measurement setups. Storage vessels The fully PFA insulated VEGAFLEX 83 is ideal for level measurement in vessels in the food processing and pharmaceutical industries. The sensor can be set up without filling or adjustment with medium. Fully insulated rod probes are available in lengths up to 4 m (13 ft) and cable probes up to 32 m (105 ft). The wetted parts are made of the food safe plastics PFA and TFM-PTFE. The measurement is unaffected by product characteristics such as density, temperature or...

Open the catalog to page 13All VEGA TECHNIQUE catalogs and technical brochures

-

VEGAPULS 42

2 Pages

-

VEGAFLEX 86

2 Pages

-

VEGAFLEX 83

2 Pages

-

VEGAFLEX 82

2 Pages

-

VEGAFLEX 82, 86

24 Pages

-

VEGAFLEX 81

2 Pages

-

VEGAFLEX 81, 83, 86

28 Pages

-

Guided Wave Radar

3 Pages

-

Radar IIoT

4 Pages

-

Radar

6 Pages

-

VEGAPULS 6X

20 Pages

-

VEGAPULS 6X

2 Pages

-

VEGAPULS Air 42

2 Pages

-

VEGAPULS Air 41

2 Pages

-

VEGAPULS Air 23

2 Pages

-

VEGAPULS WL 61

2 Pages

-

VEGAPULS WL S 61

2 Pages

-

VEGAPULS SR 68

2 Pages

-

VEGAPULS 69

2 Pages

-

VEGAPULS 68

2 Pages

-

VEGAPULS 67

2 Pages

-

VEGAPULS 66

2 Pages

-

VEGAPULS 65

2 Pages

-

VEGAPULS 64

2 Pages

-

VEGAPULS 63

2 Pages

-

VEGAPULS 62

2 Pages

-

VEGAPULS 61

2 Pages

-

VEGAPULS 31

3 Pages

-

VEGAPULS 21

2 Pages

-

VEGAPULS 11

3 Pages

-

VEGAPULS C 23

2 Pages

-

VEGAPULS C 22

2 Pages

-

VEGAPULS C 11

2 Pages

-

VEGAPULS C 21

2 Pages

-

Radar

16 Pages

-

WEIGHTRAC 31

2 Pages

-

Hydrostatic VEGABAR, VEGAWELL

12 Pages

-

Microwave barrier VEGAMIP

12 Pages

Archived catalogs

-

Radar VEGAPULS

22 Pages