Catalog excerpts

ALTERNATIVE FUELS AND RAW MATERIALS TECHNOLOGY FOR A SUSTAINABLE TOMORROW

Open the catalog to page 1

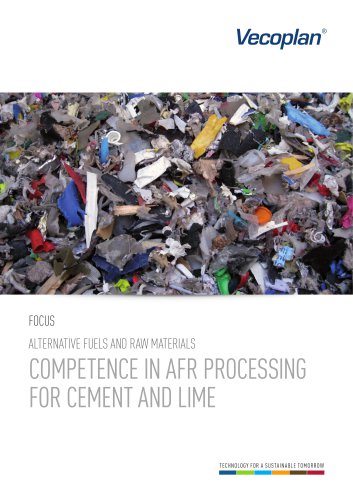

Identification Analyzing and Assessing According to the four steps, before choosing and preparing alternative materials it is important to analyze and assess the materials for their suitability in the clinker burning process with regard to chemistry, emission and environmental impact as well as its potential behavior in the burning process. Their sustainable, ecologic and economic availability has to be analyzed and evaluated. Identification Feedstock for alternative Fuel and Raw material can be nearly anything: residues, wastes or biomasses in liquid, pasty or solid form. HIGHFRACTION...

Open the catalog to page 2

Industrial Waste Municipal Waste Bulky household Waste Demolition Waste Tyre Chips Service, Engineering and Supply for Alternative Fuels and Raw Materials in Cement and Lime Industry Cement industry and its cement production is under continuous economic and ecological pressure. Reducing fuel cost and cutting the CO2-emission are the top requirements. For both an increased use of AFR – Alternative Fuels and Raw materials – is a good answer. The controlled usage of AFR has no negative effect on the basic emission of the plant, nor on the clinker burning process nor on the product quality. It...

Open the catalog to page 3

Reprocessing Residues, wastes and biomass in nearly undefined size and form are typically either separately or jointly pre-processed to remove minerals and organics, metals, glass, ash or other harmful constituents from the fuel. After shredding, sieving, screening and/or separation we receive a Highly enriched Caloric Fraction (HCF) with a lump size of less than 300 mm. Material pre-sorting

Open the catalog to page 4

Heavy rejects Pre-sorted, baled industrial waste To storage or loading or treating to RDF < 80 mm / SRF < 30 mm An ideal pre-shredder is the well-established 2-rotor preshredder type „Hurricane“, characterized by a high throughput, its robustness and insensitiveness against interferent of any kind, low maintenance requirement and high availability and flexible low power high torque drive system. Vibrating screens sieve the unwanted minerals and organics efficiently out. Overbelt magnets or magnetic drums reduce contents of disturbing iron. The separation with the airknife separator takes...

Open the catalog to page 5

Handling and Dosing Processed fuel not going direct from the processing plant to the consumer in the cement plant may need truck transport and subsequently truck unloading at the plant level. The shown Truck Unloading Station (TULS) has the special feature of working nearly dust- and spillage-free without the need for a dedusting system. Unloading capacities up to 350 m³/h are possible. It takes moving-floor as well as tipping truck trailers. Other TULS designs in single or double trailer reception are also available depending on the actual situation. Within the RDF/SRF handling the...

Open the catalog to page 6

Quality, Ecology, Economy At the end of a tailor-made AFR process installation comes the check for clinker product quality and the questions for improvement of Ecology and Economy have to be asked and answered. Depending on the results further optimization of the individual processing steps may be necessary or the fuel cycle must be gone through again starting with the selection and assessment of new AFR feedstock.

Open the catalog to page 7

Your Partner VECOPLAN AG Vor der Bitz 10 56470 Bad Marienberg | Germany Phone: +49 (0) 2661.62 67-0 Fax: +49 (0) 2661.62 67-70 vecoplan@vecoplan.de www.vecoplan.com Wolfram Zschiesche Sales and Engineering Phone +49 (0) 2661.62 67-470 Mobile +49 (0) 151.12 15 73 76 wolfram.zschiesche@vecoplan.de Patryk Adam Max Sales and Engineering Phone +49 (0) 2661.62 67-884 Mobile +49 (0) 172.4 14 15 77 patryk.max@vecoplan.de Michael Held Sales and Engineering Phone +49 (0) 2661.62 67-876 Mobile +49 (0) 172.1 70 80 03 michael.held@vecoplan.de Boris Sassenrath Sales Director Cement Phone...

Open the catalog to page 8All Vecoplan catalogs and technical brochures

-

Single-shaft pre-shredder

6 Pages

-

Alternative fuel shredder

6 Pages

-

Machine Fire Protection

2 Pages

-

Biomass chippers series

7 Pages

-

FOCUS VDS 800

9 Pages

-

VD 1100

7 Pages

-

VEZ 2500

2 Pages

-

V-ECO 1700

2 Pages

-

V-ECO 2100

2 Pages

-

VDS 800

2 Pages

-

DOMESTIC AND COMMERCIAL WASTE

18 Pages

-

PLASTICS

18 Pages

-

ALTERNATIVE FUELS (RDF)

18 Pages

-

BIOMASS & PELLETIZING

18 Pages

-

WOOD

18 Pages

-

PRODUCT CATALOGUE

108 Pages

-

VTH 20

2 Pages

-

VTH 12

2 Pages

-

VVZ - VNZ

2 Pages

-

TAIFUN 190

2 Pages

-

V-EBS 2500

2 Pages

-

VAZ 2000-2500

4 Pages

-

VAZ 1800

2 Pages

-

VAZ 2400 S

2 Pages

-

VAZ 800 XL - 1100 XL

2 Pages

-

VECOPLAN corporate brochure

32 Pages

-

VAZ 800

2 Pages

-

HR 35

2 Pages

-

VTH 20

2 Pages

-

VVZ 210 T

2 Pages

-

VNZ 200 XL - 250 XL

2 Pages

-

VAZ 1300- 1600 XLM

2 Pages

-

VTH 8

2 Pages

-

VAZ 700 Z

2 Pages

Archived catalogs

-

VAZ 2000 - 2500

2 Pages