Catalog excerpts

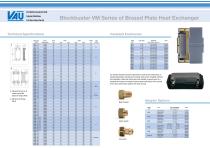

Design, Construction and Effectiveness… Through a special process, stamped stainless steel plates are vacuum oven brazed using 99.9% pure copper, as the brazing agent. The unique stamping pattern of the stainless steel plates creates the ideal fluid flow path through both the primary and secondary channels for maximum heat transfer. The result: we call it our VAU Blockbuster; an ultra efficient and compact device with an excellent price to performance ratio. The VAU Blockbuster VM Series of Brazed Plate Heat Exchangers is a robust product lineup that provides a compact, ultra efficient heat transfer solution appropriate for all stainless steel/copper-compatible liquid-liquid heat transfer applications, within device specification parameters. 435 psi (30 bar) 383 °F (195 °C) AISI 316L SS (1.4404) Copper EU Declaration of Conformity – Annex VII of Directive 97/23/EC Maximum operating parameters are permissible only under static conditions. Constant and significant changes in pressure and/ or temperature can stress the device and should be avoided. Contact information At VAU, we are here to assist you with all of your heat transfer projects. With more than 25 years experience designing, engineering, and manufacturing heat exchangers, we have the technical expertise and know-how to formulate an innovative solution for your heat transfer application. VAU Thermotech`s facility in Munich, Germany GRAFIKDESIGN Meike Hannig, München; PRODUKTFOTOGRAFIE Jens Bruchhaus, München; PRINT Druckerei Friesl, München Maximum operating pressure: Maximum operating temperature: Plate Material: Brazing Material: Certification: VAU BLOCKBUSTER Brazed Plate Heat Exchanger

Open the catalog to page 1

Verfahrenstechnik Apparatebau Blockbuster VM Series of Brazed Plate Heat Exchanger Technical Specifications SERIES, SIZE, PLATES a) Standard Version for all models except VM Series 85 Flange DN 50 b) VM Series 85 Flange DN 50 Insulated Enclosures PORT FITTINGS SERIES, SIZE DIMENSIONS Depth x Width x Height (mm) Our standard insulated enclosure (right photo) is made of form-fitted, black, expanded polypropylene and features two sturdy halves which fit together perfectly with integrated, molded self-locking tabs. Also available, by special order, is a hardened shell variety of insulated...

Open the catalog to page 2All VAU Thermotech GmbH & Co. KG catalogs and technical brochures

-

Brazed Plate Heat Exchanger

9 Pages

-

Plate Heat Exchanger

12 Pages

-

Technical datasheet VM 15

7 Pages