Catalog excerpts

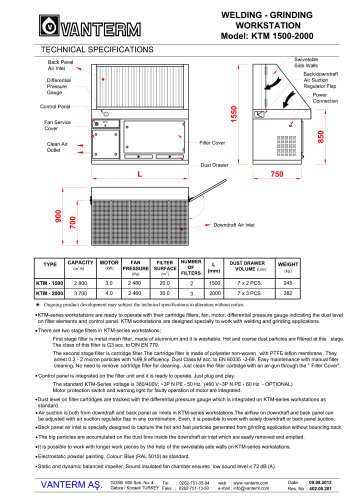

WELDING - GRINDING TECHNICAL SPECIFICATIONS Back Panel Control Panel Filter Cover Dust Drawer Side Walls Regulator Flap ® Ongoing product development may subject the technical specifications to alteration without notice. •KTM-series workstations are ready to operate with their cartridge filters, fan, motor, differential pressure gauge indicating the dust level on filter elements and control panel. KTM workstations are designed specially to work with welding and grinding applications. • There are two stage filters in KTM-series workstations; First stage filter is metal mesh filter, made of aluminium and it is washable. Hot and coarse dust particles are filtered at this stage. The class of this filter is G3 acc. to DIN EN 779. The second stage filter is cartridge filter.The cartridge filter is made of polyester non-woven with PTFE teflon membrane. They arrest 0.2 - 2 micron particles with %99,9 efficiency. Dust Class M acc. to EN 60335 -2-69. Easy maintenance with manual filter cleaning. No need to remove cartridge filter for cleaning. Just clean the filter cartridge with an air-gun through the" Filter Cover". • Control panel is integrated on the filter unit and it is ready to operate. Just plug and play. The standard KTM-Series voltage is 380/400V; ~3P N PE - 50 Hz. (460 V~3P N PE - 60 Hz - OPTIONAL) Motor protection switch and warning light for faulty operation of motor are integrated. •Dust level on filter cartridges are tracked with the differential pressure gauge which is integrated on KTM-series workstations as • Air suction is both from downdraft and back panel air inlets in KTM-series workstations.The airflow on downdraft and back panel can be adjusted with air suction regulator flap in any combination. Even, it is possible to work with solely downdraft or back panel suction. • Back panel air inlet is specially designed to capture the hot and fast particles generated from grinding application without bouncing back. • The big particles are accumulated on the dust bins inside the downdraft air inlet which are easily removed and emptied. • It is possible to work with longer work pieces by the help of the swivelable side walls on KTM-series workstations. • Electrostatic powder painting. Colour: Blue (RAL 5010) as standard. •Static and dynamic balanced impeller. Sound insulated fan chamber ensures low sound level $ 72 dB (A). GOSB 800 Sok. No: 4 Tel : 0262-751-05-94 web : www.vanterm.com Date : 09.08.2012 Gebze / Kocaeli TURKEY Faks : 0262-751-13-50 e-mail: info@vanterm.com Res. No : 402.00.201

Open the catalog to page 1All Vanterm Isı ve Makina San. Tic. A.Ş. catalogs and technical brochures

-

SM-Series FILTER UNITS

2 Pages

-

AC-Series FILTER UNITS

2 Pages

-

M-Series Mobile FILTER UNITS

2 Pages

-

PLK-150

1 Pages

-

ACW-123...ACW-404

3 Pages

-

PM - 801, IFA-certified

2 Pages

-

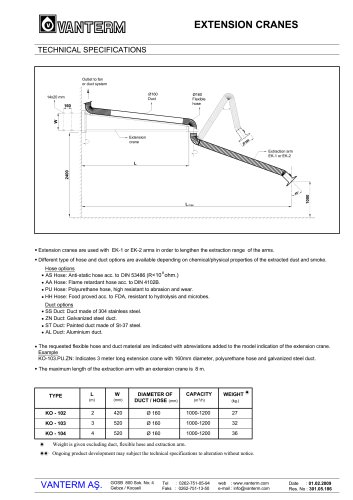

Extension Cranes

1 Pages

-

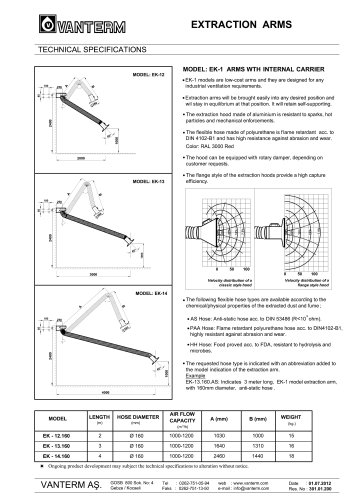

Extraction Arms

1 Pages

-

Cutting Tables

3 Pages

-

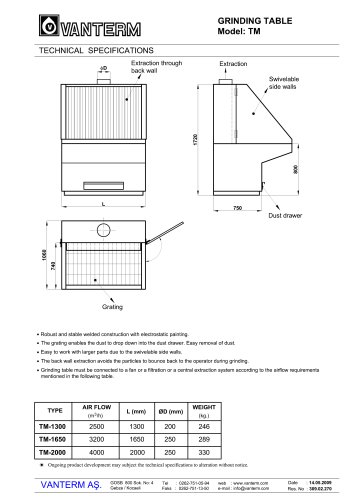

TM - Grinding Tables

1 Pages

-

AC - Filter Units

2 Pages

-

AB - Filter Units

2 Pages

-

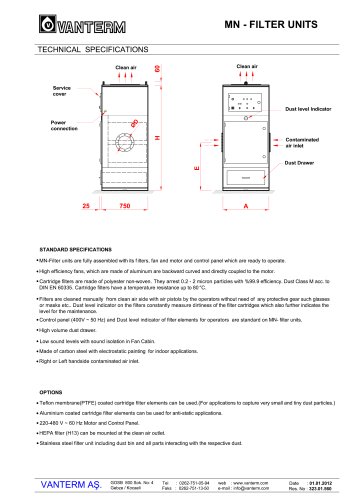

MN - Filter Units

2 Pages

-

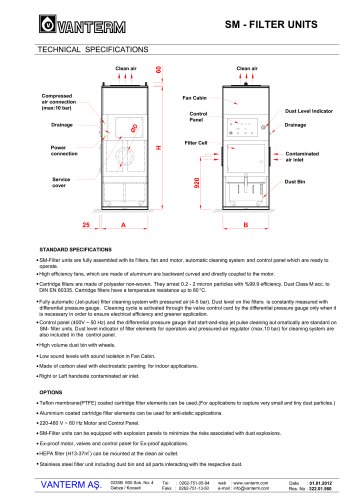

SM - Filter Units

2 Pages

-

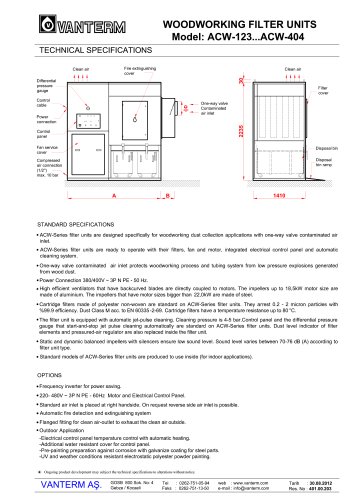

ACW - Filter Units

3 Pages

-

ABW - Filter Units

2 Pages

-

GF - Filter Units

5 Pages

-

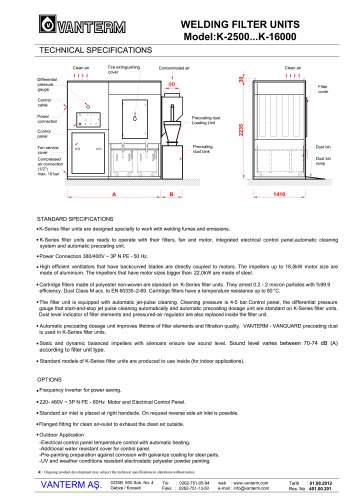

K - Welding Filter Units

3 Pages

-

Mobile Filter Units

2 Pages