Catalog excerpts

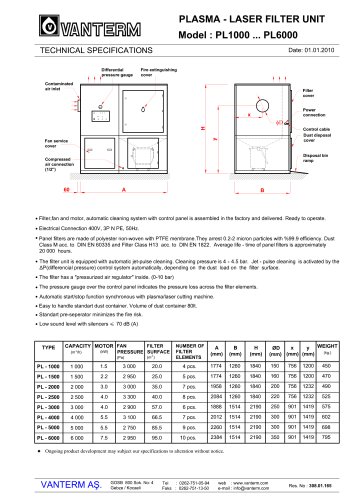

PL-Series PLASMA LASER FILTER UNITS Technical Specifications: IFA-DGUV Germany W3 certified. Cert. No: IFA 1605032 PLUG-n-PLAY Ready to operate! PL-4000 Plasma Laser Filter Unit W3 Certified. PL-Series filter units are specifically designed for extraction and dedusting of dust, fume and smoke generated during plasma, laser and OXY cutting operations. Plasma and laser cutting applications requires special design and unique features which cannot be satisfied by regular dust collectors because Cutting fumes are essentially very fine particles of ave. 0,15 microns which may cause immediate filter clogging at regular dust collectors. Filter cleaning and regeneration are very difficult to achieve for sustainable operation and reasonable spare filter replacement and maintenance intervals. There is a very high risk of fire, due to smoldering hot particles that are generated during thermal cutting operation if proper precautions have not been held. VANTERM PL-Series filter units with W3 dedusting Class certification and filter elements average lifetime of 20 000 hours are proven their fitness for the job with thousands of applications all over the world. Thanks to the HEPA 14 filter quality of VANTERM Panel Filter Technology, PL Dust collectors separate the ultra-fine dust particles including as small as 0,12 microns with 99,997% filtration efficiency. All PL-Series Filter Units are W3 Certified and delivered ready to operate as standard. Dedusting Class: W3 according to EN ISO 15012-1 Power Input: 400V ~ 3P PE - 50 Hz. Pre-Separator: Aerodynamic Spark separation in order to minimize fire risk. Fan: Aluminum High Efficiency Radial Backward Curved G2.5 balanced with Direct Coupling following ERP 2015. Filter Type: Panel Pleated Surface Filtration Dust Class M and H14 ePTFE membrane Polyester Non-woven. Filter Efficiency: HEPA14 certified acc. To EN 1822 standard – Filter Efficiency Over 99,997% of 0,12 micron particles. Filter Life time: Average 20 000 h state-of-the-art filter lifetime above industry standards with cutting edge filter design, media and cleaning system. Filter Cleaning: VANTERM K-type fully automatic Differential Pressure (ΔP) controlled with high efficiency solo jet-pulse cleaning. Pressured Air Input: min.6 bar (Reduced to 4,5 bar internally with built-in regulator) Sound level: Extreme Low sound level below ≤69 dB(A) with built-in silencer after fan. Dust laden air is extracted from cutting bench of laser, plasma or Oxy cutting unit. First, dust laden enters the pre-separator chamber where hot and big particles are separated from main stream aerodynamically. Afterwards, dust laden air is filtered at the panel pleated filters. Clean air is extracted through fansilencer group and returned clean as VANTERM PL-Series are W3 certified. When K-type VANTERM filter cleaning system senses that filters are needed to clean, Jet-pulse filter cleaning is activated in order to clean panel pleated filters elements. A sudden burst of pressured air is released to clean filter by freeing the pores of the filter media and shaking of dust cake on the elements. Operation Mode: Panel Operation and slave mod (with NO relay connection from parent) as standard. Output Signals: Digital Motor Fault, Normal Operation and Low Air Flow Signals Dust Bin: Easy to Handle locking mechanism 80 to 160-liter capacity. Any three phase Voltage and frequency (ex.480V ~ 3P PE 60 Hz) configuration is available upon reques

Open the catalog to page 1

FILTER AREA *Ongoing product development may subject the technical specifications to alteration without notice. Jet-pulse Cleaned Panel Filters are H14 certified. Easy Dust Bin Mechanism VANTERM Isı Ve Makina San. Tic. A.Ş. GOSB 800. Sok. No:804 41480 Gebze/Kocaeli TURKEY Tel:+90 262 751 05 94(Pbx) www.vanterm.com Low Sound Level with Silencer

Open the catalog to page 2All Vanterm Isı ve Makina San. Tic. A.Ş. catalogs and technical brochures

-

SM-Series FILTER UNITS

2 Pages

-

AC-Series FILTER UNITS

2 Pages

-

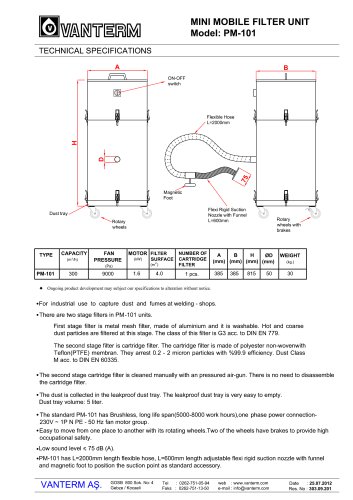

M-Series Mobile FILTER UNITS

2 Pages

-

PLK-150

1 Pages

-

ACW-123...ACW-404

3 Pages

-

PM - 801, IFA-certified

2 Pages

-

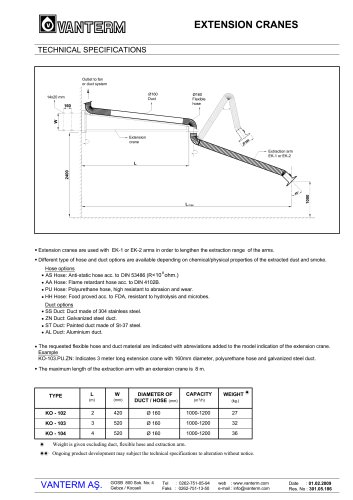

Extension Cranes

1 Pages

-

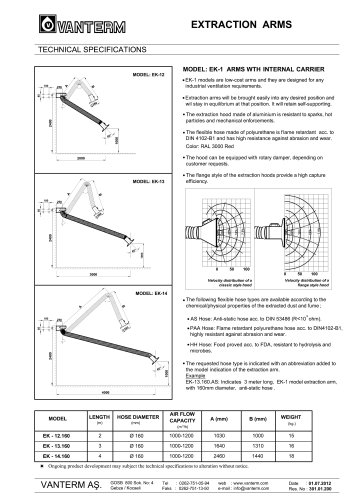

Extraction Arms

1 Pages

-

Cutting Tables

3 Pages

-

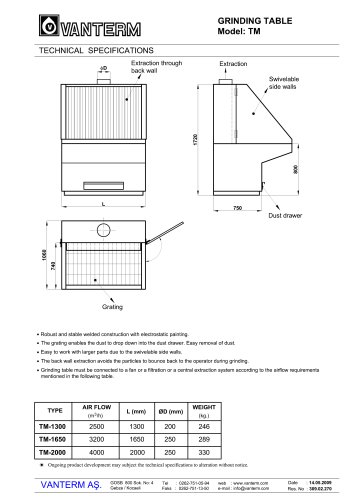

TM - Grinding Tables

1 Pages

-

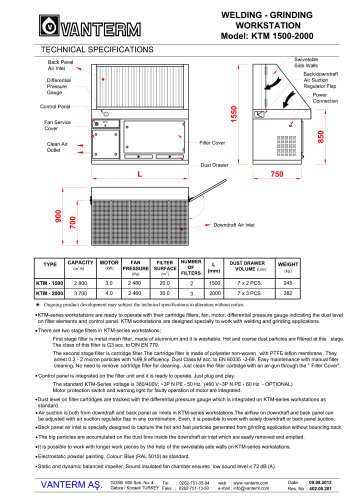

Work Benches (KTM)

1 Pages

-

AC - Filter Units

2 Pages

-

AB - Filter Units

2 Pages

-

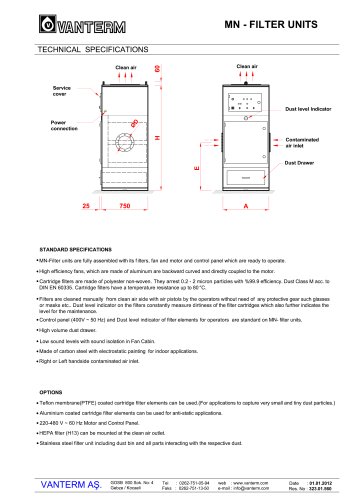

MN - Filter Units

2 Pages

-

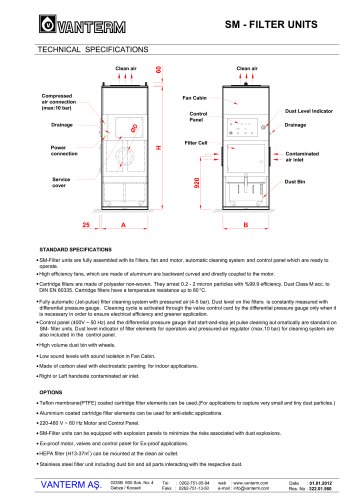

SM - Filter Units

2 Pages

-

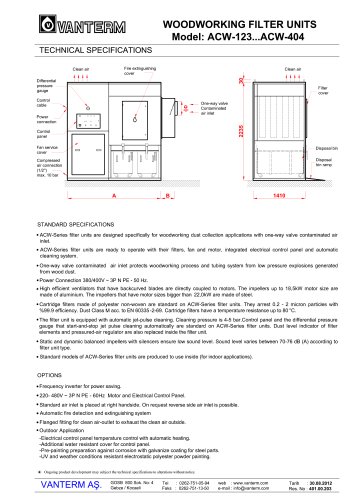

ACW - Filter Units

3 Pages

-

ABW - Filter Units

2 Pages

-

GF - Filter Units

5 Pages

-

K - Welding Filter Units

3 Pages

-

Mobile Filter Units

2 Pages