Catalog excerpts

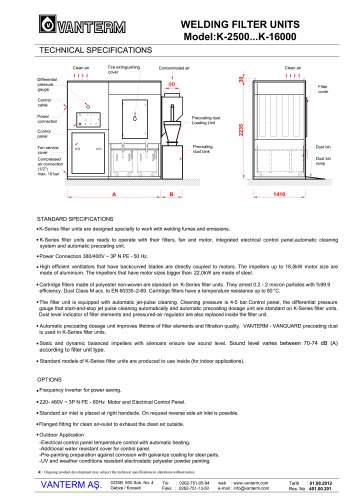

WELDING FILTER UNITS TECHNICAL SPECIFICATIONS Fire extinguishing Contaminated air Precoating dust Loading Unit dust tank STANDARD SPECIFICATIONS • K-Series filter units are designed specially to work with welding fumes and emissions. • K-Series filter units are ready to operate with their filters, fan and motor, integrated electrical control panel,automatic cleaning system and automatic precoating unit. • High efficient ventilators that have backcurved blades are directly coupled to motors. The impellers up to 18,5kW motor size are made of aluminium. The impellers that have motor sizes bigger than 22,0kW are made of steel. • Cartridge filters made of polyester non-woven are standard on K-Series filter units. They arrest 0.2 - 2 micron particles with %99.9 efficiency. Dust Class M acc. to EN 60335-2-69. Cartridge filters have a temperature resistance up to 80 °C. •The filter unit is equipped with automatic jet-pulse cleaning. Cleaning pressure is 4-5 bar.Control panel, the differential pressure gauge that start-and-stop jet pulse cleaning automatically and automatic precoating dosage unit are standard on K-Series filter units. Dust level indicator of filter elements and pressured-air regulator are also replaced inside the filter unit. • Automatic precoating dosage unit improves lifetime of filter elements and filtration quality. VANTERM - VANGUARD precoating dust is used in K-Series filter units. • Static and dynamic balanced impellers with silencers ensure low sound level. Sound level varies between 70-74 dB (A) according to filter unit type. • Standard models of K-Series filter units are produced to use inside (for indoor applications). • Frequency inverter for power saving. •220- 480V ~ 3P N PE - 60Hz Motor and Electrical Control Panel. • Standard air inlet is placed at right handside. On request reverse side air inlet is possible. • Flanged fitting for clean air-oulet to exhaust the clean air outside. • Outdoor Application -Electrical control panel temperature control with automatic heating. -Additional water resistant cover for control panel. -Pre-painting preparation against corrosion with galvanize coating for steel parts. -UV and weather conditions resistant electrostatic polyester powder painting. @ Ongoing product development may subject the technical specifications to alterations without notice. Gebze / Kocaeli Faks : 0262-751-13-50 e-mail: info@vanterm.com

Open the catalog to page 1

WELDING FILTER UNITS TECHNICAL SPECIFICATIONS Fire extinguishing Contaminated air Precoating dust Loading Unit dust tank ® Ongoing product development may subject the technical specifications to alterations without notice. Gebze / Kocaeli Faks : 0262-751-13-50 e-mail: info@vanterm.com

Open the catalog to page 2

WELDING FILTER UNITS TECHNICAL SPECIFICATIONS Fire extinguishing Precoating dust Contaminated air ^ Precoating dust ® Ongoing product development may subject the technical specifications to alterations without notice. Gebze / Kocaeli Faks : 0262-751-13-50 e-mail: info@vanterm.com

Open the catalog to page 3All Vanterm Isı ve Makina San. Tic. A.Ş. catalogs and technical brochures

-

SM-Series FILTER UNITS

2 Pages

-

AC-Series FILTER UNITS

2 Pages

-

M-Series Mobile FILTER UNITS

2 Pages

-

PLK-150

1 Pages

-

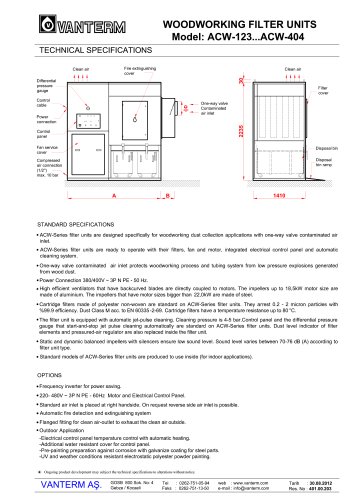

ACW-123...ACW-404

3 Pages

-

PM - 801, IFA-certified

2 Pages

-

Extension Cranes

1 Pages

-

Extraction Arms

1 Pages

-

Cutting Tables

3 Pages

-

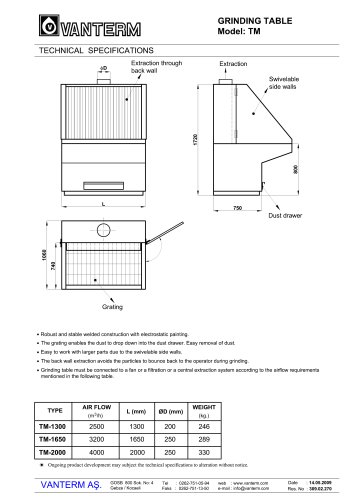

TM - Grinding Tables

1 Pages

-

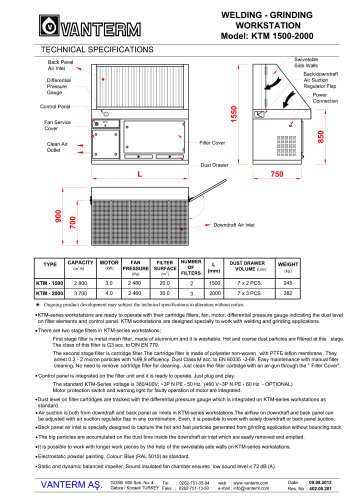

Work Benches (KTM)

1 Pages

-

AC - Filter Units

2 Pages

-

AB - Filter Units

2 Pages

-

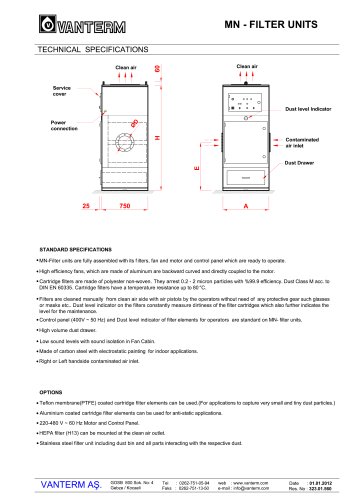

MN - Filter Units

2 Pages

-

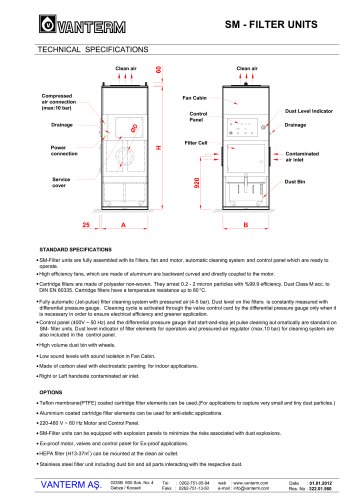

SM - Filter Units

2 Pages

-

ACW - Filter Units

3 Pages

-

ABW - Filter Units

2 Pages

-

GF - Filter Units

5 Pages

-

Mobile Filter Units

2 Pages