Catalog excerpts

BG-Series Mobile FILTER UNITS Technical Specifications: PLUG-n-PLAY Ready to operate! BG-1500 Filter Unit with HEPA 14 Filter Module BG – model mobile filter units are designed for filtration of dry dust, generated during various industrial operations (i.e. grinding, brushing, shaking, mixing etc.) BG filter unit is delivered as a ready-to-operate dust collector with cartridge and optional cassette filter elements, fully integrated fan, automatic reverse jet pulse filter cleaning system and control panel. BG – filter units can be used with VANTERM EK-2 type extraction arms or with duct connection, depending on the applied process. High filtration efficiency with Dust Class: M certified (acc. to EN 60335-2-69) filter elements which arrests 0,2-2 micron particles with 99,9% efficiency. Average 10000-15000 working hour lifespan with effective reverse jet-pulse cleaning. Visual real-time dust level control of filter elements via colored manometer. Maximum operational safety with fully integrated control panel and internal electrical wiring. The light-weight fan impellers are made of aluminum, which ensures long motor life-time. High efficient, backward curved fans confirming ERP 2015 with G2.5 balance grade (static and dynamic) are direct coupled to motors. Dirty-air inlet part avoids particles from striking onto the filter elements and extends the filter life-time. Low consumption of pressured-air with ∆P controlled automatic VANTERM K-type jet-pulse cleaning. The service access door and the control panel cover are all replaced on the front side of the filter unit. With Dust Class-M standard cartridge filters, the filtered-clean air can be returned back to the workshop. This prevents heat loss and ensures environment friendly and healthy application. User-friendly, big dust tray with its 64 lt. high volume brings advantage for daily maintenance work. Depending on various industrial operations, BG – filter units can be equipped with optional Aluminum coated, ePTFE Teflon membrane, and Flame Retardant Polyester nonwoven filter elements, on request. The stopper parts inside service door keep the dust tray always in its position- unaffected from the movements of the filter unit. The stopper parts inside service door keep the dust tray always in its position. On request, the separation degree is much more enhanced with optional HEPA 13 filter module. On request, BG-filter units can be equipped with activated carbon filter modules, to be used at processes where smoke and dust particles create odor and smell problems. The front side is enough for all maintenance and service needs. One side is for dust-laden air connection. The rest sides can be replaced anywhere. – Saves space on production ground. All Electrical Voltage and Frequency configurations (i.e. 480V 3P~60 hz.) are available, on

Open the catalog to page 1

*Ongoing product development may subject the technical specifications to alteration without notice. The motor is replaced inside the filter unit, to provide low sound level during operation. The filter unit can be easily equipped with HEPA filter chamber or Carbon filter chamber later after sales, on customer request. Easy maintenance for motor, fan and filter elements with the hinged front covers. User friendly front covers are simply locked or unlocked. In standart version, the cartridge filters are made of polyester non-woven. They arrest 0.2 - 2 micron particles with %99.9...

Open the catalog to page 2All Vanterm Isı ve Makina San. Tic. A.Ş. catalogs and technical brochures

-

SM-Series FILTER UNITS

2 Pages

-

AC-Series FILTER UNITS

2 Pages

-

M-Series Mobile FILTER UNITS

2 Pages

-

PLK-150

1 Pages

-

ACW-123...ACW-404

3 Pages

-

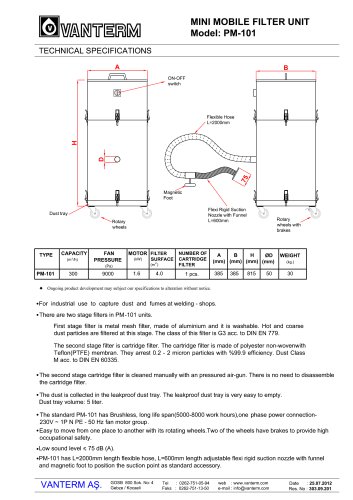

PM - 801, IFA-certified

2 Pages

-

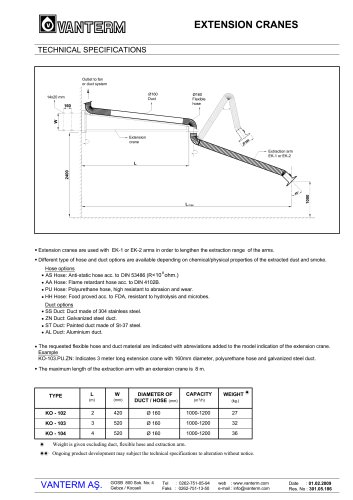

Extension Cranes

1 Pages

-

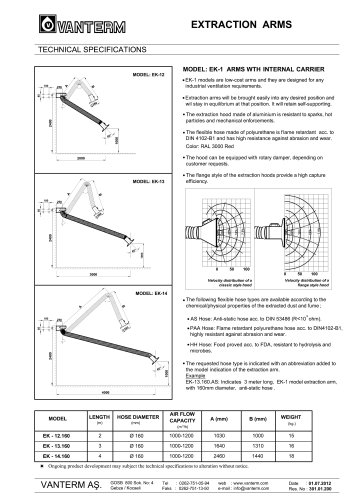

Extraction Arms

1 Pages

-

Cutting Tables

3 Pages

-

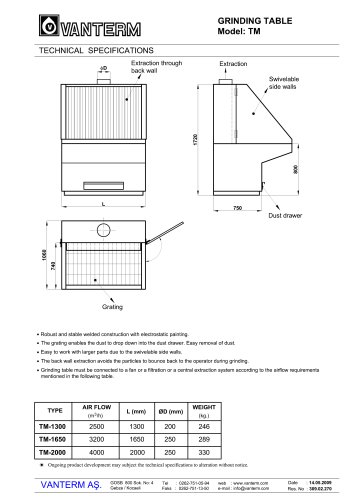

TM - Grinding Tables

1 Pages

-

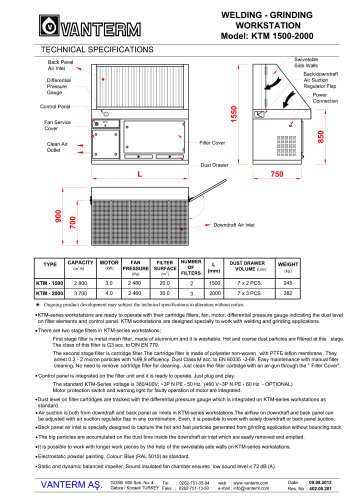

Work Benches (KTM)

1 Pages

-

AC - Filter Units

2 Pages

-

AB - Filter Units

2 Pages

-

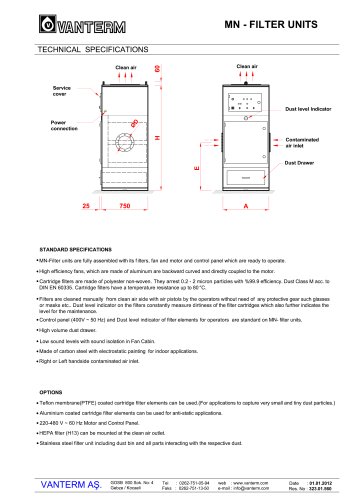

MN - Filter Units

2 Pages

-

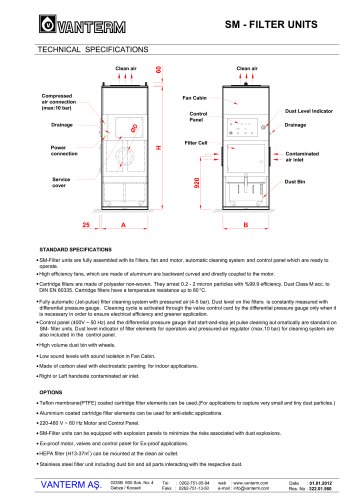

SM - Filter Units

2 Pages

-

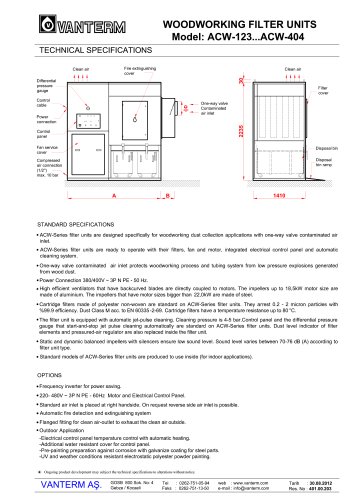

ACW - Filter Units

3 Pages

-

ABW - Filter Units

2 Pages

-

GF - Filter Units

5 Pages

-

K - Welding Filter Units

3 Pages

-

Mobile Filter Units

2 Pages