Catalog excerpts

AC-Series FILTER UNITS Technical Specifications: AC-323-INV Filter Unit Power Control and Saving with Automatic Pressure Transmitter Controlled VFD PLUG-n-PLAY Ready to operate! Designed for dedusting of dry dust, generated during various industrial operations (i.e. sandblasting, welding, mixing etc.) Ready-to-operate with filters, integrated fan, automatic jet pulse filter cleaning system and control panel. Availability of placing filter unit adjacent to corners and walls – Saves space on production ground. Low Sound Level ≤70-75dB(A) depending on model. High filtration efficiency with Dust Class: M certified (acc. to EN 60335-2-69) filter elements which arrests 0,2-2 micron particles with 99,9% efficiency. Dedusting Class W3 certification according to EN ISO 15012-1 is in progress. Maximum operational safety with fully integrated control panel and internal electrical wiring. Visual real-time dust level control of filter elements via manometer. With Dust Class M filters, filtered-clean air recycled to the plant environment prevents heat loss and ensures environment friendly and healthy application. Low consumption of pressured-air with ∆P controlled automatic VANTERM K-type jet-pulse cleaning. As standard slave mod available, automatic start and stop synchronous with the related parent process. All Electrical Voltage and Frequency configurations (ex.480V 3P~60 hz.) are available with automation and power control implemented via worldwide available components. OPTIONAL-Automatic PID control with pressure transmitter regulated VFD (Variable Frequency Drive) for fan speed control ensures energy saving with optimum performance. OPTIONAL - Low air flow output signal and alarm ensure handson approach for performance observation, process safety and maintenance. OPTIONAL-Aluminum coated, ePTFE Teflon membrane, Flame Retardant Polyester and Stainless steel construction Propylene nonwoven filter elements are available on request. Ave. 10000-15000 working hour lifespan with specially designed filter cartridges, effective jet pulse cleaning and integrated inlet diffuser which ensures impact-free entrance. The fan impellers up to 18,5kW motor sizes are made of aluminum. The fan impellers, bigger than 18,5kW, are made of steel. All fans confirming ERP 2015 with G2.5 balance grade (static and dynamic). Easy access doors to every component solely from the front side of the filter unit. Unique dust bin locking mechanism, dust bins are unlocked, offloaded and replaced in matter of seconds. Easy Access to Cartridge Filters Diffuser entry Easy Dust Bin Mechanism Self-Tapped Cartridges are easy

Open the catalog to page 1

*Ongoing product development may subject the technical specifications to alteration without notice. Ready-to-operate with filters, built-in fan-motor group, silencer and control panel. Electrical connection 400V, 3P PE ~ 50Hz as standard. (Different electrical supply configuration options are availableOn Request such as 480V, 3P PE ~ 60Hz. etc.) High efficiency, backward curved blade, statically and dynamically balanced fans are directly coupled to the motor. Standard air inlet is placed at right hand-side from front view. (Left hand-side air inlet available-On Request.) ∆P...

Open the catalog to page 2All Vanterm Isı ve Makina San. Tic. A.Ş. catalogs and technical brochures

-

SM-Series FILTER UNITS

2 Pages

-

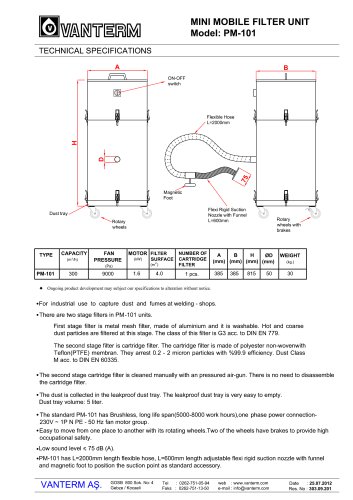

M-Series Mobile FILTER UNITS

2 Pages

-

PLK-150

1 Pages

-

ACW-123...ACW-404

3 Pages

-

PM - 801, IFA-certified

2 Pages

-

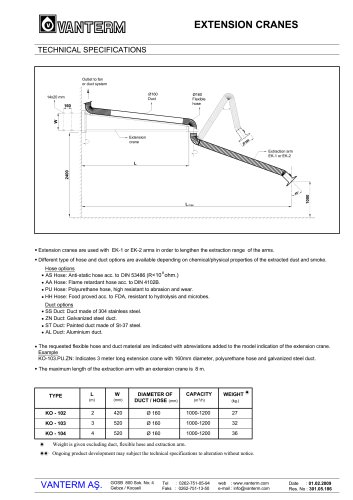

Extension Cranes

1 Pages

-

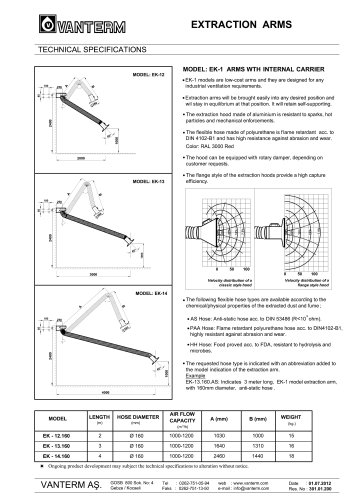

Extraction Arms

1 Pages

-

Cutting Tables

3 Pages

-

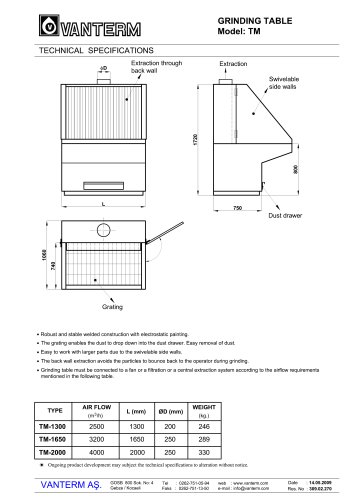

TM - Grinding Tables

1 Pages

-

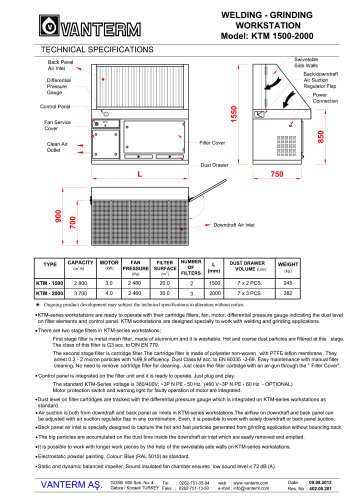

Work Benches (KTM)

1 Pages

-

AC - Filter Units

2 Pages

-

AB - Filter Units

2 Pages

-

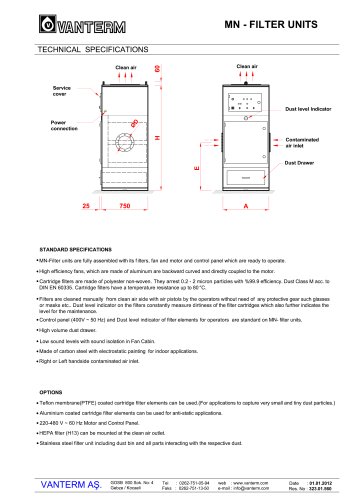

MN - Filter Units

2 Pages

-

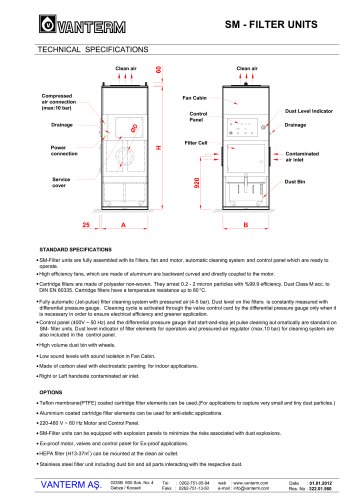

SM - Filter Units

2 Pages

-

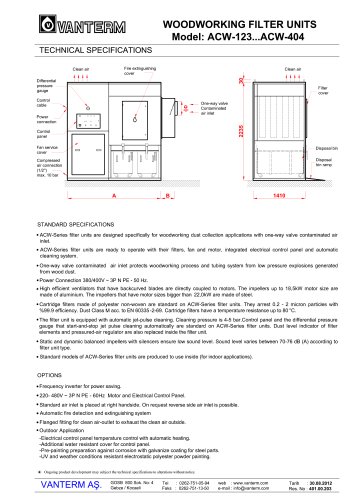

ACW - Filter Units

3 Pages

-

ABW - Filter Units

2 Pages

-

GF - Filter Units

5 Pages

-

K - Welding Filter Units

3 Pages

-

Mobile Filter Units

2 Pages