Catalog excerpts

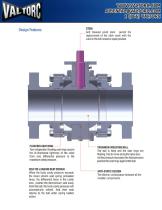

Design Features FLOATING SEATRING Two independent floatingseat rings assure the bi-directional tightness of the valve from zero differential pressure to the maximum rated pressure. Anti blowout proof stem permn the replacement of the stem seals with the valve inthe full closed or open pos ilion. The ball is fixed and the seat rings are lloating, free to movealong thevalve axis. As the pressureincreases the ftuid pressure pushes the seat rings against theball. SELF RE·LEANING SE TDESIGN A When the body cavity pressure exceeds the down stream seat spring preloaded force, the differential...

Open the catalog to page 2

DOUBLE BLOCK AND BLEED Independent spring loaded floating seats maintain contact with the baJI and provide an effective tight shut off at tow pressure differential. Independent upstream and down stream seats permtt raining of fluids from the body cavity, allowing double block and bleed operation. BODY JOINTS The dooble body seals O·rlngs and lire safe grapMe gasket in all static joints of the body components ensures protection against external leakage and fugttive emission requirements. FIRE SAFE , PRIMARY METAL :SECONDARY SOFT SEAT. FIRE SAFE , PRIMARY SOFT SECONDARY METAL SEAT. A...

Open the catalog to page 3

FLAME KILLING

Open the catalog to page 4

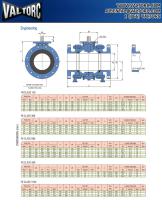

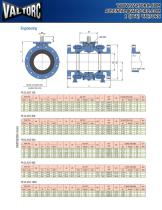

FLMGE DRILLING

Open the catalog to page 6

Pressure Temperature Ratings A Torque Values Pressure - temperature seal ratings of valves are as given in Ihe graph frjr body material ASTIW A 216 ■ Gr. WCB. With lhe exception of body seat rings and primary stilt seals, all valve components are capable of withstanding the pressure - temperature jgtings as specified in ASME a 15.34, 0$ 1560: Pari II. BS45M: Parti or BS 5351 as applicable. Temperature Limits

Open the catalog to page 8

MATERIAL OF CONSTRUCTION / EXPLODED VIEW DEVLON ,' NYLON [PA12| / DELRIN ,' NPTFE / PEEK I PCTFE ! CGfTV WON STUD, BOLT : PART LIST EXPLODED VIEW

Open the catalog to page 9

CODES & STANDARDS .; Design Standards :- AP16D I ASME 16.34 I EN ISO 17292 ( BS 55351) •. Face TOFace :- API 60 I ASME 16.10 I EN ISO 17292 •• Inspection & Testing :- AP15981 EN 12266-1 Pressure T emperature :- ASME B 16.34 .; Flange Dimensions :- ASME B 16.51 MSS-SP - 44/ ASME B 16.1 •: Fire Sale Test :- API 607 / ISO 104971 API 6FA I EN 12266-2 G Box O ear perated All Valves wtth gear operator for manual operation, pad locking arrangement is provided as an option to prevent unauthorized operation. Actuator O perated All valves can be direct mounted wtth pneumatic actuators or electric...

Open the catalog to page 10All Valtorc catalogs and technical brochures

-

545SN series

2 Pages

-

535SN series

2 Pages

-

SANITARY BUTTERFLY VALVE

2 Pages

-

Series CS/SS 2000

4 Pages

-

Solenoid Valve

4 Pages

-

BALL-VALVE-SERIES-190

1 Pages

-

BALL-VALVE-SERIES-200

1 Pages

-

BALL-VALVE-SERIES-210

1 Pages

-

BALL-VALVE-SERIES-220

1 Pages

-

BALL VALVE SERIES 230

1 Pages

-

ball-valve-series-110

1 Pages

-

ball-valve-series-100

1 Pages

-

awwa butterfly valve

5 Pages

-

Ball valve

1 Pages

-

SERIES-IP6000

4 Pages

-

UPS-SERIES9

1 Pages

-

VP-700-POSITIONER

5 Pages

-

ACTUATED VALVE PACKAGE

4 Pages

-

ACTUATION

4 Pages

-

BALL VALVE

4 Pages

-

BUTTERFLY VALVE

4 Pages

-

FIRE SAFE FUSIBLE LINK VALVE

4 Pages

-

KNIFE GATE

4 Pages

-

POULTRY

1 Pages

-

SANITARY VALVE

4 Pages

-

V BALL - V PORT

4 Pages

-

460 series

2 Pages

-

390 series

4 Pages

-

FS-30

4 Pages

-

FS10 series

1 Pages

-

LSN7 series

6 Pages

-

LSN4-SS

1 Pages

-

Limit Switch LSN4

2 Pages

-

9AAG-GOLD

1 Pages

-

VP V-Port Valve

4 Pages

-

Series PV 620 Plug Valves

1 Pages

-

Series PV 610 Plug Valves

1 Pages

-

Series PV 600 Plug Valves

3 Pages

-

VP-900 Positioner

3 Pages

-

VP-700 Positioner

5 Pages

-

Solenoid Valve 9AAG

2 Pages

-

Limit Switch LSN7

6 Pages

-

quarter turn valve actuator

4 Pages

-

ups9-series

1 Pages

-

900 series

2 Pages

-

800 series

2 Pages

-

EL700V

15 Pages

-

gate globe valve

15 Pages

-

pvc valve

4 Pages

-

solenoid valve

10 Pages

-

PVC strainer

1 Pages

-

flanged gate valve

1 Pages

-

gate valve

1 Pages

-

control ball valve

6 Pages

-

check valve

1 Pages

-

safety-relief valve

5 Pages

-

control-valve

4 Pages

-

sanitary-check-540-sn

2 Pages

-

600 series

3 Pages

-

300 series

10 Pages

-

100 series

1 Pages

-

pneumatic actuator

4 Pages

-

EL 750

5 Pages

-

EL600

6 Pages