Catalog excerpts

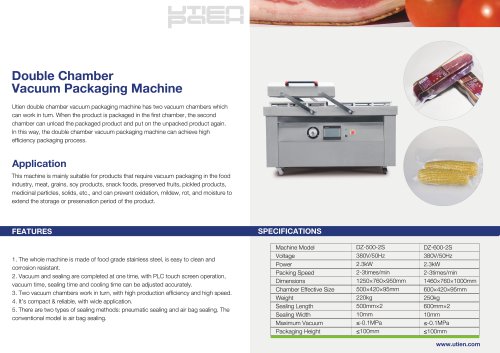

Control Panel Switch I.Power switch & Power lamp Power switch control the power supply of the whole machine which is indicated by a green lamp. II.Heating switch Turn on the heating switch to proVde electrical power for sealing bar. III.Starting switch Press the starting switch to start compressing and sealing process. IV. Emergency switch Press the emergency switch while emergency situation appeared. V. Heating timer & Cooling timer The timers control the time of heating and cooling which are two major parameters for the sealing process, VI. Fuse Protect the machine from electrical power...

Open the catalog to page 2

Working Procedure I.Turn on the power switch and heating switch. II.Place the product on the compress area. And lean the openning on the aluminium sealing bar.Then adjust the position of the package. III.Change the heating time and cooling time to right parameter.With normal vcacuum pocket(PE+PA) the heating time will be vary from 0.8-1,5s and cooling time will be 4-5s. IV.Press the starting switch to start sealing process. After the process, take out the compressed product and check the sealing.

Open the catalog to page 3

Sealing Length Package Height (max) Working Procedure Beady Position Utien Pack Co., Ltd 255 Shuguang Rd, Kebei Industrial Zone, Shaoxing, Zhejiang 312081,China Tel:+86 575 8110 7017 Fax:+86 575 8110 7023 Web:www.utien.com e-mail:export@utien.com

Open the catalog to page 4All Utien Pack Co. catalogs and technical brochures

-

Banner Welder Machine

2 Pages

-

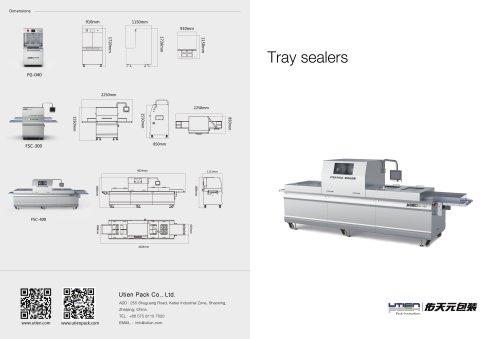

Tray Sealers

6 Pages

-

Continuous Tray Sealer

4 Pages

-

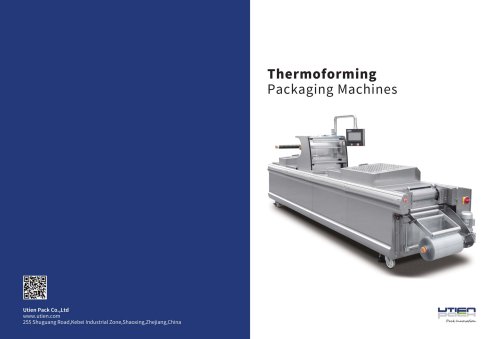

Thermoforming Machines

8 Pages

-

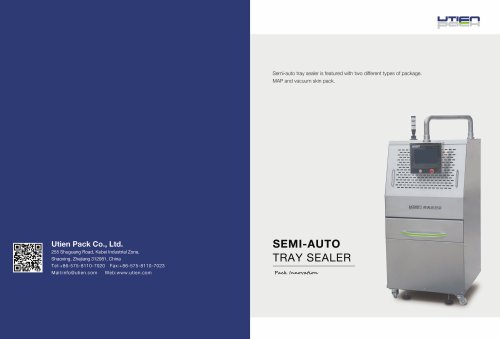

SEMI-AUTO TRAY SEALER

2 Pages

-

FMQZ-1600/2

4 Pages