Website:

USEON Technology Limited

Website:

USEON Technology Limited

Group: Useon Group

Catalog excerpts

. Applications* Features Control system

Open the catalog to page 1

■ Applications ■ Features ■ Jumbo ■ U+ ■ Tandem ■ Data sheet ■ Pelletizer ■ Control system USEON has been pushing the boundary of China-made twin screw extruders. Since the first set of China-made high torque twin screw extruder installed in 2007 at Useon, there has been more than 2700 sets of Useon-made high-performance twin screw extruders working worldwide. Over the years, SAT series have stood the test of time. Now the brand-new SAT series redefine the art of the state. S-Safety—stability creates productivity. Safety provides stability. SAT series are designed on the basis of sufficient...

Open the catalog to page 2

SAT series stands for Useon ’ s standard compounder for most polymer processing. We not only provide high quality machines, but also can help you develop the new applications of SAT. The screw speed ranges from 100 up to 1200rpm. The L/D ration covers from 20 up to 72. The degassing or vacuum system and side feeders can be incorporated into SAT system easily. It provides the optimal cost-effective investment.

Open the catalog to page 3

■ Applications ■ Features ■ Jumbo ■ U+ ■ Tandem ■ Data sheet ■ Pelletizer ■ Control system New SAT is able to achieve more delicate processing task, precise process control can meet complicate and sophisticate processing purpose. Better dispersion, more accurate temperature control and higher throughput have been integrated and optimized further. The procedural steps in compounding include: Plasticizing and Alloying Filling and Reinforcing ► Carbon black ► Ti02 ► Color pigment ► Mono MB for fiber ► Filler (CaCo3/BaS04/Talc) ► Anti-UV ► Anti-static ► Dehumidify (CaO) ► Flame-retardants ►...

Open the catalog to page 4

SAT authentically explains one-for-multiple. More powerful gearbox, more precise screw elements endow SAT more flexible processing range and wider operation window. We also provide individual solution according to customized requirements. Variety of modular screw elements, barrels, melt filtration and pelletizing system will cater for your unique requirement. Pressurization > Filtering > Pelletizing > Packing Cable and Wires ► PVC series ► HFFR ► PE series ► XLPE ► Special cables PET Recycle ► Bottle flakes ► PSF (popcorn) ► PET sheet scrap ► BOPETfilm ► Online waste Reactive Extrusion ►...

Open the catalog to page 5

■ Applications ■ Features ■ Jumbo ■ U+ ■ Tandem ■ Data sheet ■ Pelletizer ■ Control system Precise screw elements made by CNC tools provide SAT better intermeshing and self-wiping performance which ensures the entire processing no dead corner and better control in RTD (residence time distribution). The ratio of outside diameter and inside diameter determines the free volume. SAT series extruder feature the excellent self-wiping functions. Combining with screw torque and free volume, the Do/Di of SAT is optimized at 1.55 that provide sufficient torque while remain enough free volume. Except...

Open the catalog to page 6

Barrels / Liners SAT adopts ingenious cooling channel design which provides more efficient cooling performance and easier maintenance job. Modular design allows barrel sequence can be optimized with different barrel material as per the characteristic of processing task. To ensure the precision, all SAT barrels are processed by CNC machines and checked by CMM (Coordinate Measuring Machine). We have various barrel structures to cater for different feeding types, venting types and liquid injection. Material Description Hardness Abrasion Corrosion Through hardened alloy steel Through hardened...

Open the catalog to page 7

USEON-patented High Torque Gearbox The perfect concept of the split-transmitting principle has been successfully applied in USEON-patented gearbox with the digital online monitoring system; each gearbox is assembled with precise positioning for torque balance. Thanks to our special CNC tools for gearbox and gearbox parts that ensures its durability and high torque output. With 15Nm/cm3 specific torque, SAT meets mainstream European standard which means SAT can work under lower temperature with higher throughput. Gearbox for Parallel Triple Screw The free volume of screw increase by 40%,...

Open the catalog to page 8

■ Applications ■ Features ■ Jumbo ■ U+ ■ Tandem ■ Data sheet ■ Pelletizer ■ Control system U+ Compounder U+ series twin screw extruder is the highest-level series of USEON, mainly specialized for products that require high speed and high torque, such as engineering plastics, masterbatch and other applications. FEATURED DESIGN High torque: torque of 15Nm/cm3 , meeting higher filling rate and production capacity, greatly improving productivity with reduced specific energy input. High speed: maximum screw speed up to 1200r, configured screw speed and motor based on process tasks. High...

Open the catalog to page 9

■ Applications ■ Features ■ Jumbo ■ U+ ■ Tandem ■ Data sheet ■ Pelletizer ■ Control system Pelletizing System Water Cooling Strand Pelletizing System It is suitable for most polymer compounding production, which features simple structure, easy operation and convenient maintenance. The threshold of operators is also low. This system consists of strand die, water batch, air knife, strand pelletizer and vibrating classifier. Under Water Strand Pelletizing System It is suitable for plastic recycling which needs to change the filter frequently. The strands go into the pelletizer automatically...

Open the catalog to page 10

This system incorporates with single stage extruder. It is suitable for certain recipes, such as PP base filler degradable and WPC, which is too sticky to be cut by air cooling die face pelletizer. The other merit of this system is that it lets the material avoid contracting with water. This system includes die head, air cooling belt conveyor, strand pelletizer and vibrating classifier. Air Cooling Die Face Pelletizing System This system incorporates with tandem compounder. It is suitable for certain recipes, such as PVC, LLDPE, high filling masterbatch, degradable masterbatch, HFFR, WPC...

Open the catalog to page 11

■ App“'“s ■ ^ ■u+■ T-dem ■-—■ p*,,z“ ■&n,rai -,em Water Ring Pelletizing System It is suitable for certain recipes, such as PE/PS/EVA/TPU etc. The final pellet looks nicer and has good flowability. The length of production line is shorter than that of strand pelletizing. This system includes water ring pelletizer, water circulating system, centrifugal dewater and vibrating classifier. Underwater Pelletizing System Underwater pelletizing system can handle almost all kinds of polymers. Comparing with other pelletizer, underwater is more compacted which is more obvious when the output is huge....

Open the catalog to page 12All USEON Technology Limited catalogs and technical brochures

-

Quality & Productivity

4 Pages

-

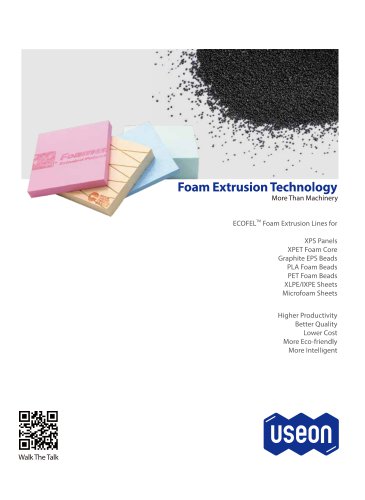

Foam Extrusion Technology

12 Pages

Archived catalogs

-

ECOFEL XPS Production Line

8 Pages

-

Sheet Extrusion Lines

8 Pages

-

Foam Extrusion Lines

8 Pages

-

Extruders Brochure

12 Pages

-

SAT COMPOUNDER

16 Pages

-

xps production line-co2

6 Pages

-

Extruders

12 Pages

-

WPC Material Production Line

4 Pages

-

PET Extrusion Technology

6 Pages