Catalog excerpts

Urschel® Model CCL Lattice Slicer OPERATING PRINCIPLE The Model CCL is equipped with manganese aluminum bronze contact parts. Product delivered to the feed hopper enters the revolving impeller assembly [ 1 ] consisting of four rotating potato holding tubes [ 2 ]. The tubes allow the potato to be rotated in a vertical axis while being revolved in a radial direction. Centrifugal force holds the potatoes tightly against the inside surface of the spherical-shaped slicing head. As the potatoes rotate inside the slicing head, they make an approximate one-quarter turn between each of the four crinkle knife stations [ 3 ]. This results in intersecting crinkles on each side of the slice. Length: . . . . . . . . . . . . . . . . . . . . . 48.03" (1220 mm) Width: . . . . . . . . . . . . . . . . . . . . . . . 35.26" (896 mm) Height: . . . . . . . . . . . . . . . . . . . . . . . 32.68" (830 mm) Net Weight: . . . . . . . . . . . . . . . . . . . . 540 lb (245 kg) Motor: . . . . . . . . . . . . 2 HP (1.5 kW) or 5 HP (3.7 kW) APPLICATIONS The Model CCL slicer produces lattice cuts of varying thickness. Both sides of the slice have crinkles, with the crinkles on each side of the slice running approximately 90° to each other. Uses involve lattice potato chips and thicker potato waffle fries. Lattice slicing is a unique application. Proper feeding of the machine is necessary to ensure continuous production. Tempered high quality oval or flat shaped potatoes measuring between 2 – 4 inches (51 – 102 mm) are best-suited. Note: The Model CC Slicer can be converted to a Model CCL Lattice Slicer by purchasing the recommended set of parts. Contact your local Urschel representative for more information. Fine Lattice: Translucent appearance with small lattice holes visible after frying. 8 corrugations per inch (25.4 mm). Approximately .125" (3.2 mm) peak to peak. Coarse Lattice: Small lattice holes visible. 5.7 corrugations per inch (25.4 mm). Approximately .175" (4.4 mm) peak to peak. Deep Lattice: Slightly larger lattice holes. 2.25 corrugations per inch (25.4 mm). Approximately .446" (11.2 mm) peak to peak. If your product application is not mentioned on this page, contact your local Urschel representative to determine the most effective solution to your size reduction needs.

Open the catalog to page 1

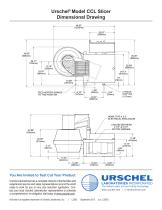

Urschel® Model CCLSIicer Dimensional Drawing FEED HOPPER SWINGS ELECTRICAL ENCLOSURE CHOOSE BETWEEN — MOTOR W/BRAKE You Are Invited to Test Cut Your Product Urschel Laboratories has a complete network of test facilities and experienced service and sales representatives around the world ready to work for you on any size reduction application. Con- tact your local Urschel Laboratories' representative to schedule a comprehensive, no-obligation test today at www.urschel.com. LABORATORIES INCORPORATED The Global Leader in Food Cutting Technology ©Urschel is a registered trademark of Urschel...

Open the catalog to page 2All Urschel Laboratories catalogs and technical brochures

-

SH-14

4 Pages

-

SL-14

3 Pages

-

HOW TO CUT SEAFOOD PRODUCTS

5 Pages

-

HOW TO CUT PET FOOD PRODUCTS

5 Pages

-

HOW TO CUT DAIRY PRODUCTS

5 Pages

-

HOW TO CUT MEAT PRODUCTS

5 Pages

-

URSCHEL GRINDING MACHINES

13 Pages

-

GENERAL BROCHURE

17 Pages

-

URSCHEL® MODEL CC-D

2 Pages

-

URSCHEL® MODEL CC-DL

2 Pages

-

URSCHEL® MODEL CCX-D

2 Pages

-

AFFINITY INTEGRA® DICER

2 Pages

-

DiversaCut SPRINT® Dicer

2 Pages

-

DiversaCut 2110A™ Dicer

2 Pages

-

AFFINITY® Dicer

2 Pages

-

Sprint 2™

2 Pages

-

TranSlicer® 2510 Cutter

2 Pages

-

TranSlicer 2000® Cutter

2 Pages

-

Urschel® Model W

2 Pages

-

Urschel® Model OC

2 Pages

-

Urschel® Model CC

2 Pages

-

Comitrol® 3600

2 Pages

-

E TranSlicer®

2 Pages