Catalog excerpts

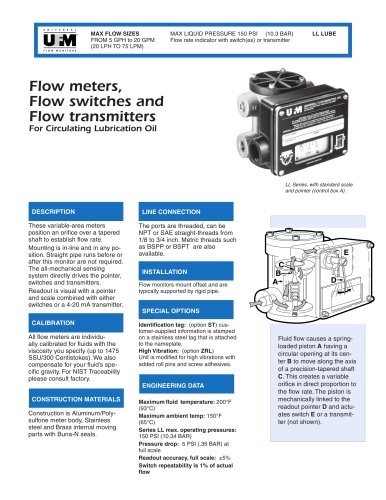

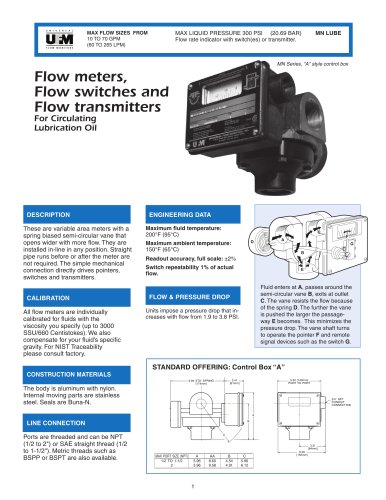

U N I V E R S A L ® F L O W MAX FLOW SIZES FROM 5 GPH to 20 GPM (20 LPH TO 75 LPM) MAX LIQUID PRESSURE 150 PSI (10.3 BAR) Flow rate indicator with switch(es) or transmitter LL LUBE M O N I T O R S Flow meters, Flow switches and Flow transmitters For Circulating Lubrication Oil LL Series, with standard scale and pointer (control box A). DESCRIPTION These variable-area meters position an orice over a tapered shaft to establish ow rate. Mounting is in-line and in any position. Straight pipe runs before or after this monitor are not required. The all-mechanical sensing system directly drives the pointer, switches and transmitters. Readout is visual with a pointer and scale combined with either switches or a 4-20 mA transmitter. LINE CONNECTION The ports are threaded, can be NPT or SAE straight-threads from 1/8 to 3/4 inch. Metric threads such as BSPP or BSPT are also available. INSTALLATION Flow monitors mount offset and are typically supported by rigid pipe. SPECIAL OPTIONS CALIBRATION All ow meters are individually calibrated for uids with the viscosity you specify (up to 1475 SSU/300 Centistokes). We also compensate for your uid’s specic gravity. For NIST Traceability please consult factory. Identication tag: (option ST) customer-supplied information is stamped on a stainless steel tag that is attached to the nameplate. High Vibration: (option ZRL) Unit is modied for high vibrations with added roll pins and screw adhesives. ENGINEERING DATA CONSTRUCTION MATERIALS Construction is Aluminum/Polysulfone meter body, Stainless steel and Brass internal moving parts with Buna-N seals. Maximum uid temperature: 200°F (93°C) Maximum ambient temp: 150°F (65°C) Series LL max. operating pressures: 150 PSI (10.34 BAR) Pressure drop: 5 PSI (.35 BAR) at full scale Readout accuracy, full scale: ±5% Switch repeatability is 1% of actual ow Fluid ow causes a springloaded piston A having a circular opening at its center B to move along the axis of a precision-tapered shaft C. This creates a variable orice in direct proportion to the ow rate. The piston is mechanically linked to the readout pointer D and actuates switch E or a transmitter (not shown).

Open the catalog to page 1

HOW TO ORDER Select appropriate symbols and build a model code number, as in example shown: EXAMPLE: SERIES Normal pressure (150 PSI) HOUSING and PISTON MATERIAL Aluminum/polysulfone body with brass piston INTERNAL MOVING PARTS Stainless Steel SEAL MATERIAL Buna N LL - ABP = S B 1.5GM - 3L - 4ØCS.9 - LL = ABP = S = B MAX FLOW RATE LIQUIDS Viscosity minimum (SSU/Centistokes) 500/110 250/55 100/20 None 5, 1Ø, 15, 2Ø, 25, 3Ø, 4Ø, 5Ø, 6Ø, 75, 8Ø, 9Ø, 1ØØ, 12Ø, 15Ø, 2ØØ, 25Ø & 3ØØ = Ø.25, Ø.5, Ø.75, 1, 1.5, 2, 2.5, 3, 4, 5, 6, 7, 8, 9, 1Ø, 15 & 2Ø = 5, 1Ø, 15, 2Ø, 25, 3Ø, 35, 4Ø, 5Ø, 6Ø, 7Ø & 75...

Open the catalog to page 2

A1 W SERVICE Oil and dust tight (Type 12) = Weatherproof (Type 4) = Weatherproof, corrosion proof (Type 4X) = = = = = ZRL - .5D N W X FLOW DIRECTION Left to right Right to left Up Down L- R L U D SPECIAL OPTIONS High vibration modication (Order with A1B switch below) Stainless steel ID tag = = ZRL ST SWITCH SETTING Desired set point is assumed to be in ow units already selected (GPM). Give ow rate followed by a “D” for ow going down (ow failure) or a “U” for ow going up. .5D Example, .5D indicates a setting of .5 GPM in declining ow. Leaving this blank will result in the switch being set at...

Open the catalog to page 3All UNIVERSAL FLOW MONITORS catalogs and technical brochures

-

FLOMEC® QSE

2 Pages

-

TM SERIES

2 Pages

-

G2 SERIES

2 Pages

-

Piston Inline PI

6 Pages

-

FS series

4 Pages

-

FP series

4 Pages

-

FD series

4 Pages

-

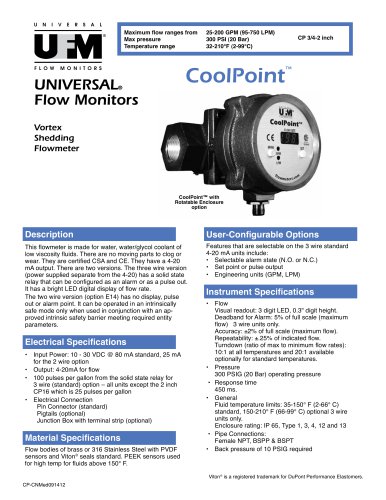

Coolpoint Large Series

4 Pages

-

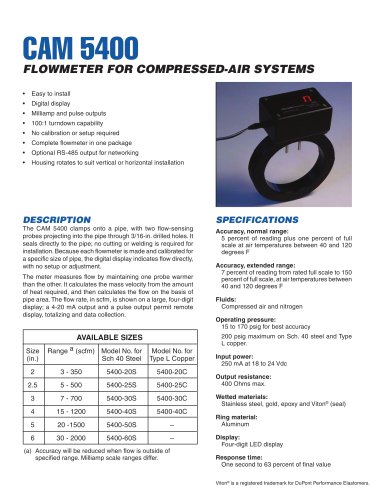

cam 5400

2 Pages

-

MX

6 Pages

-

XHF

5 Pages

-

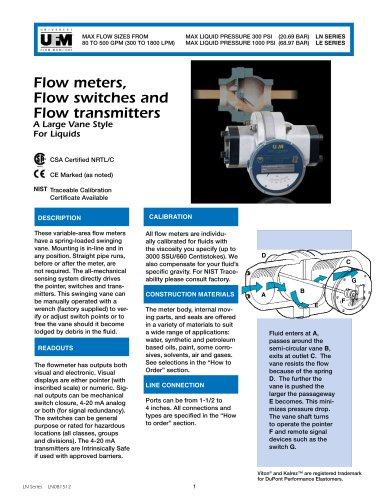

LN series

5 Pages

-

CAM 5200

2 Pages

-

OFS simplified single gas

3 Pages

-

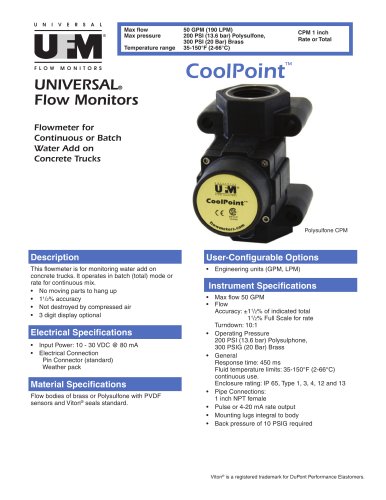

CPM

4 Pages

-

Insite Lit no TX

6 Pages

-

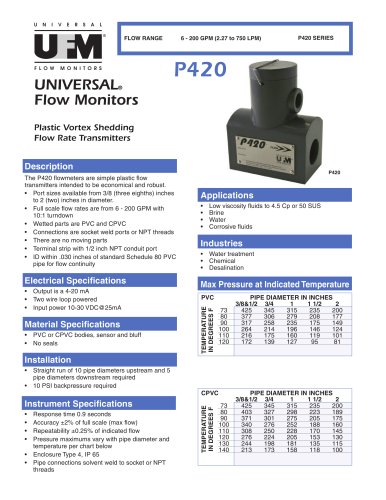

P420 Plastic Vortex Meter

2 Pages

-

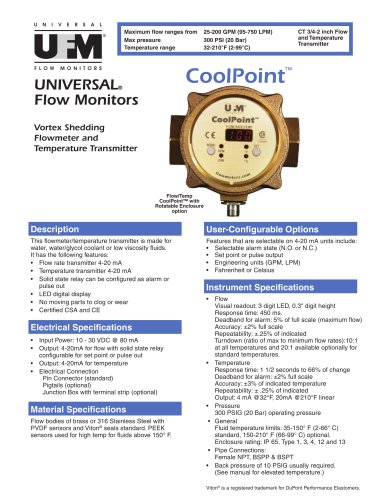

CP V8

2 Pages

-

Flow Sensor

2 Pages

-

Vortex Shedding Flowmeter

4 Pages