Catalog excerpts

FLOW Range TYPICAL APPLICATIONS • Burner Management • Leak Tests • Gas Consumption • Gas Blending • Shielding Gas • Laser Cutting • Die Casting Features • Mass flow measurement with integrated temperature and pressure correction • Visual readout of flow rate or total, pressure, and temperature • Programmable set points • No moving parts reduces maintenance • Wide turndown for precision measurement at low or high flow • 10-point calibration (NIST Traceable certificate available) General Description Laminar Flow Element differential pressure flowmeters are good for clean, dry, non-corrosive, noncondensing gasses. Corrected for temperature and pressure, it has a mass flow output. The analog (4-20 mA) output along with 2 programmable alarm set points make the meters suitable for process automation systems. NIST traceable and CSA units are Type 4 weatherproof. The accuracy is less than 1% of reading subject to limitations described in the Specifications section. The integrated LCD display can indicate flow rate or total as well as gas temperature and pressure. Calibration is done on air with empirically derived conversion factors. Oxygen cleaning optional. Sizes range from 1/8 to 3/4 inch threaded connections. Anodized aluminum is the standard material for the meter body and 316 Stainless Steel is available for use where external corrosion is

Open the catalog to page 1

Principles of Operation DIFFERENTIAL PRESSURE TEMPERATURE SENSOR ABSOLUTE PRESSURE DOWNSTREAM PRESSURE INPUT FLOW OUTPUT FLOW Laminar Flow Elements PRINCIPLES OF OPERATION: Flow of gas through a Laminar Flow Element generates a differential pressure between the absolute and downstream pressure sensors. This differential pressure is proportional to the flow velocity and viscosity of the gas. Mass flow rate is determined by utilizing the temperature and absolute pressure sensor to compensate for density variations of the gas. General Specifications Flow Ranges High Pressure Drop (2.6 psi)1...

Open the catalog to page 2

Installation Dimensions of FP Series OPTIONAL MOUNTING BRACKETS MODEL 100 SLPM 250 SLPM 500 SLPM 1000 SLPM Cable shown sold separately 0VDC (4-20mA Loop Return) +24 VDC Alarm 2 BLACK BLUE ACCESSORy CablES Available for Pin Connector Meters Series Description Length in Part Meters Number FP 5 pin 1 6241-1M female 3 6241-3M 10 6

Open the catalog to page 3

How To Order Flowstream for a Single Gas Select the appropriate symbols to build a model code: Example: SERIES = FP Material for meter body Anodized Aluminum = E 316 Stainless Steel = I Seals F Viton® = Buna N = B Pipe size in Inches NPT SAE, BSPT, BSPP 1/8 = 1 2 1/4 = 2 THREAD Type for Threaded Port NPT = N SAE = T BSPT = B BSPP = P FLOW Range IN SLPM FLOW Range IN SCFH Output 4-20 mA with 2 alarms Special options Clean for Oxygen service = C1 Vacuum Use = ZVAC Specific pressure (i.e. P10) = P___ ACTUAL GAS CALIBRATION = GAS (only available for: Helium, Nitrogen, CO2, Argon & Air)...

Open the catalog to page 4All UNIVERSAL FLOW MONITORS catalogs and technical brochures

-

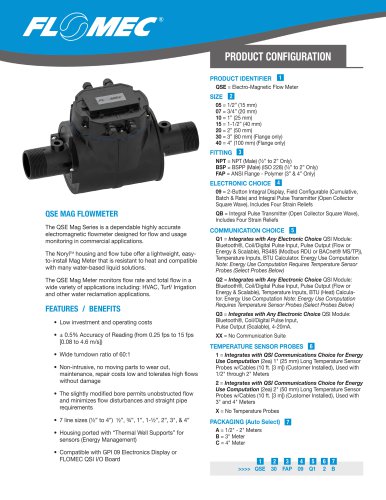

FLOMEC® QSE

2 Pages

-

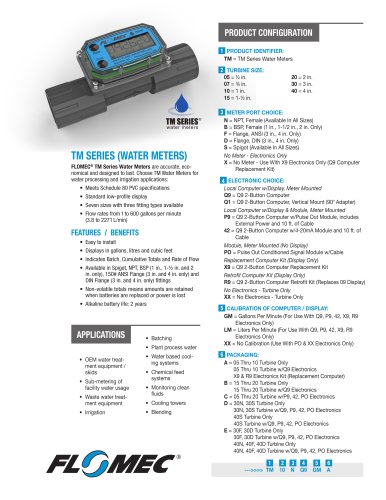

TM SERIES

2 Pages

-

G2 SERIES

2 Pages

-

Piston Inline PI

6 Pages

-

FS series

4 Pages

-

FD series

4 Pages

-

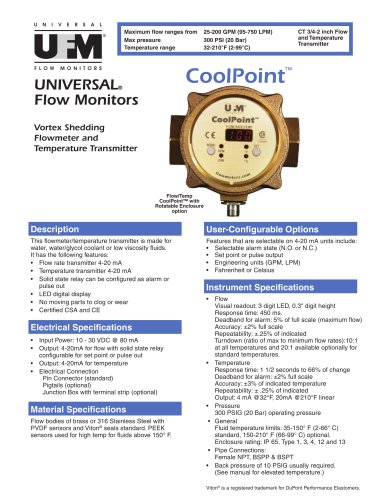

Coolpoint Large Series

4 Pages

-

cam 5400

2 Pages

-

MX

6 Pages

-

XHF

5 Pages

-

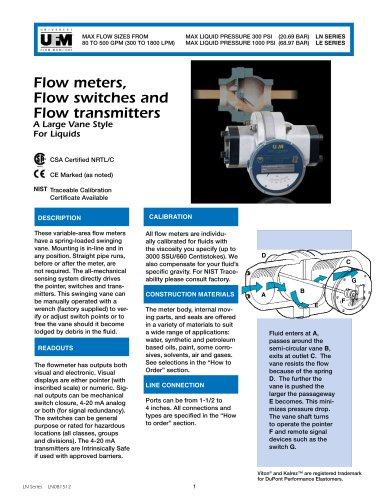

LN series

5 Pages

-

CAM 5200

2 Pages

-

OFS simplified single gas

3 Pages

-

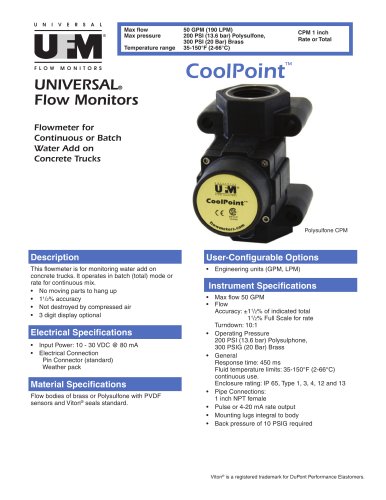

CPM

4 Pages

-

Insite Lit no TX

6 Pages

-

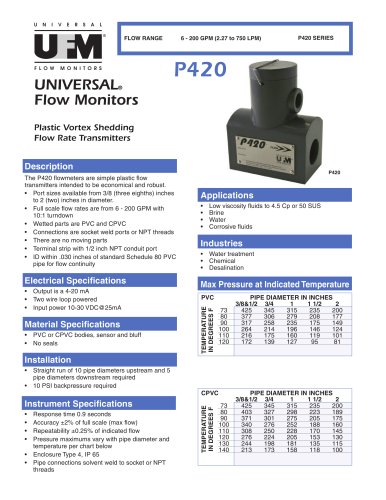

P420 Plastic Vortex Meter

2 Pages

-

CP V8

2 Pages

-

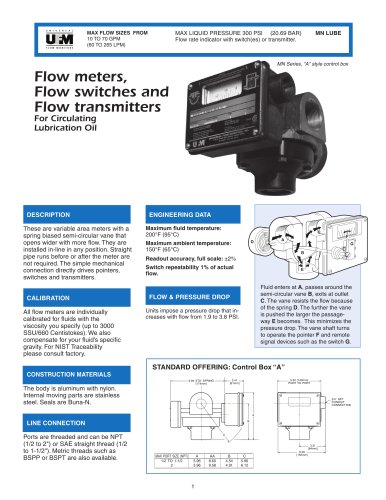

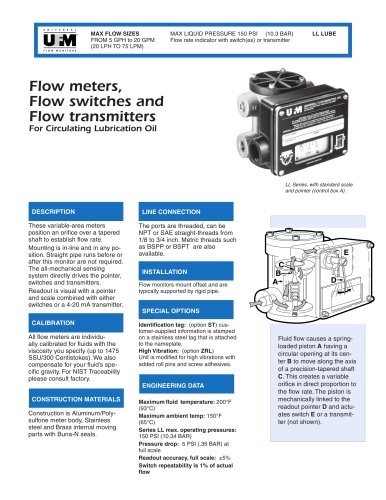

LL AX0 lube

3 Pages

-

Flow Sensor

2 Pages

-

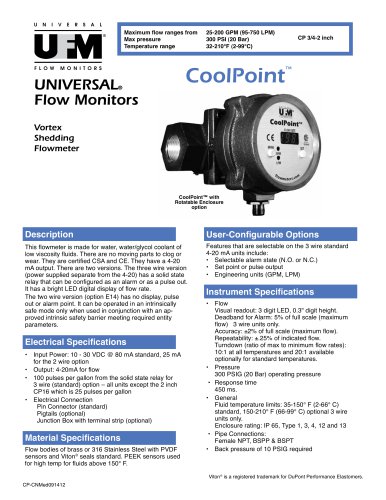

Vortex Shedding Flowmeter

4 Pages