Catalog excerpts

CAM 5400 FLOWMETER FOR COMPRESSED-AIR SYSTEMS • Digital display Milliamp and pulse outputs No calibration or setup required Complete owmeter in one package Optional RS-485 output for networking Housing rotates to suit vertical or horizontal installation The CAM 5400 clamps onto a pipe, with two ow-sensing probes projecting into the pipe through 3/16-in. drilled holes. It seals directly to the pipe; no cutting or welding is required for installation. Because each owmeter is made and calibrated for a specic size of pipe, the digital display indicates ow directly, with no setup or adjustment. Accuracy, normal range: 5 percent of reading plus one percent of full scale at air temperatures between 40 and 120 degrees F The meter measures ow by maintaining one probe warmer than the other. It calculates the mass velocity from the amount of heat required, and then calculates the ow on the basis of pipe area. The ow rate, in scfm, is shown on a large, four-digit display; a 4-20 mA output and a pulse output permit remote display, totalizing and data collection. Range a (scfm) Model No. for Sch 40 Steel Fluids: Compressed air and nitrogen Operating pressure: 15 to 170 psig for best accuracy 200 psig maximum on Sch. 40 steel and Type L copper. AVAILABLE SIZES Size (in.) Accuracy, extended range: 7 percent of reading from rated full scale to 150 percent of full scale, at air temperatures between 40 and 120 degrees F Model No. for Type L Copper (a) Accuracy will be reduced when ow is outside of specied range. Milliamp scale ranges differ. Input power: 250 mA at 18 to 24 Vdc Output resistance: 400 Ohms max. Wetted materials: Stainless steel, gold, epoxy and Viton® (seal) Ring material: Aluminum Display: Four-digit LED display Response time: One second to 63 percent of nal value Viton® is a registered trademark for DuPont Performance Elastomers.

Open the catalog to page 1

POWER SUPPLY The meter is designed for use with compressed air and nitrogen. If the meter will be used at pressures below 15 psig, consult factory about velocity limitations. The air must be free of oil, dirt that could foul the probes, and suspended water droplets. If the meter must be mounted near a compressor, isolate it from the compressor by placing it downstream of a dryer or storage tank. Each meter is calibrated for a specic size and type of pipe. Each meter is furnished with an 18-Volt, 300 mA wall-plug dc supply for 110 V main with a 20-foot cable. For 230 V main, contact...

Open the catalog to page 2All UNIVERSAL FLOW MONITORS catalogs and technical brochures

-

FLOMEC® QSE

2 Pages

-

TM SERIES

2 Pages

-

G2 SERIES

2 Pages

-

Piston Inline PI

6 Pages

-

FS series

4 Pages

-

FP series

4 Pages

-

FD series

4 Pages

-

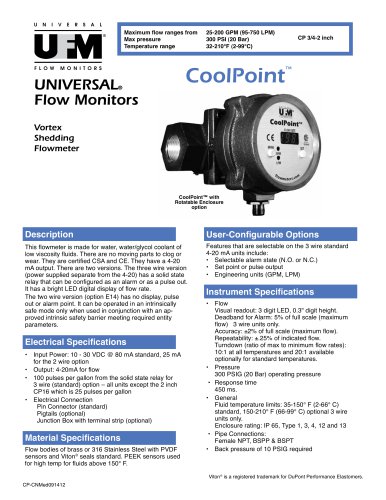

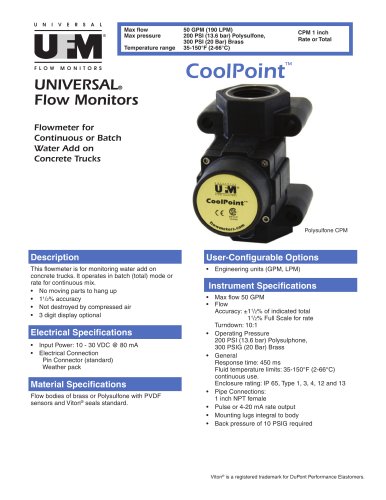

Coolpoint Large Series

4 Pages

-

MX

6 Pages

-

XHF

5 Pages

-

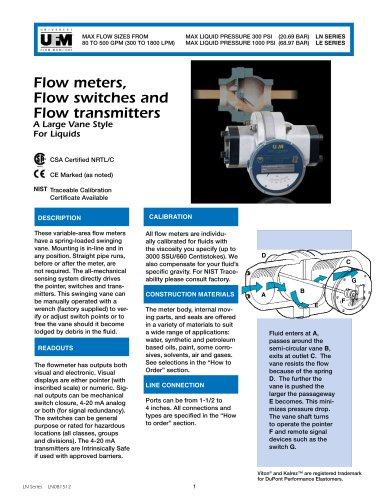

LN series

5 Pages

-

CAM 5200

2 Pages

-

OFS simplified single gas

3 Pages

-

CPM

4 Pages

-

Insite Lit no TX

6 Pages

-

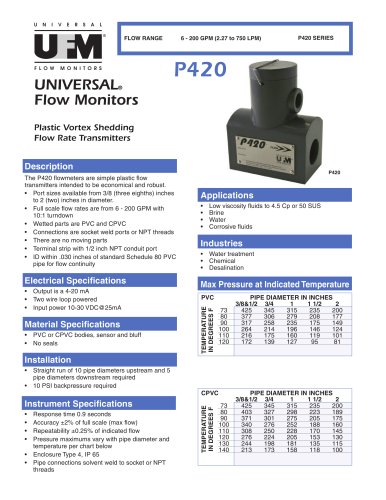

P420 Plastic Vortex Meter

2 Pages

-

CP V8

2 Pages

-

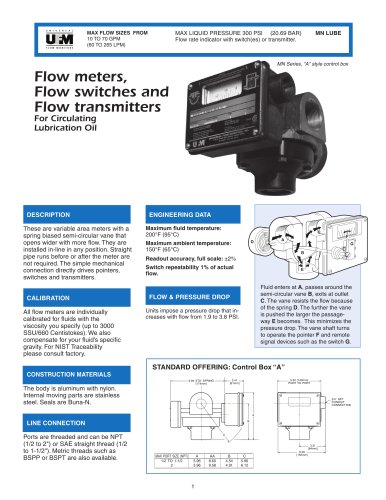

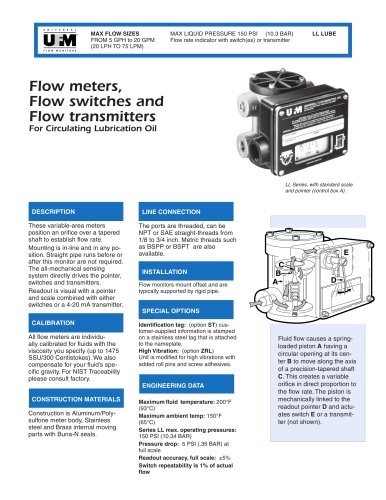

LL AX0 lube

3 Pages

-

Flow Sensor

2 Pages

-

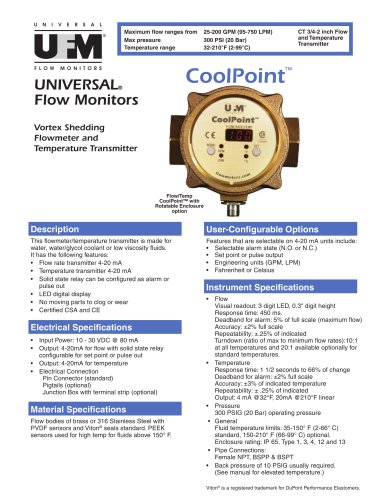

Vortex Shedding Flowmeter

4 Pages