Catalog excerpts

Electropilots Standardized valves Spool valves Poppet valves COMPACT valves Accessories VALVES Cylinders High-Tech Valves Air treatment Accessories

Open the catalog to page 1

e-mail: info@univer-group.com Internation system of units 0.07 B10 10 mm Nanovalves - higt flow rate 1.05 Standardized valves AE Light series valves for ISO 5599/1 2.15 sub-base mounting Spool valves CM Threaded spool valves E-15 5/2 M5 valves - Mechanical and manual 3.29 G7 Spool system valves 3.47

Open the catalog to page 2

G 1/8 - G 1 1/2 Poppet valves for compressed air G 1/8 - G 1 ½ Poppet valves for vacuum Miniature limit switches JET series Pneumatic limit switches Pneumatic and electric foot valves COMPACT 10 mm valves threaded body and for sub-base mounting COMPACT 15 mm valves threaded body and for sub-base mounting Accessories Coils Serial communication Analytical index

Open the catalog to page 3

UNIVER started its activity in the ‘70s in the field of industrial automation with the production of the first series of pneumatic valves and poppet valves for vacuum. In the following decades the range of technologically advanced and original pneumatic components has allowed a continuous growth and development of the company, till it has become one of the major Italian companies in the production of industrial Automation equipment. UNIVER Headquarter In the year 2000, after years of experience in the supply of pneumatic components to the Automotive market, the Automotive Division was...

Open the catalog to page 4

1970 1971 Foundation of UNIVER company 1973 Poppet valves for compressed air and vacuum First valve series Valves according to ISO 5599 (Industry Award) UNIVERSAL series valves Cylinders and mounting elements according to ISO 6431 (first cylinders on the market with extruded aluminium profile) Cylinders with antirotation piston and octagonal tube Electrically actuated microvalves Rodless cylinders (patented) Rotating cylinders (patented) Short-stroke cylinders Rodless cylinder series S1 Slide units series J Telescopic cylinders series RT COMPACT valves series P10/P15 Pneumatic/electric...

Open the catalog to page 5

>Pneumatic symbols Ways/Pos. normally closed normally open normally closed normally open separated exhausts closed centres open centres >Comparative table for port abbreviaton Symbol pressurized centres Pilot side Pilot side CONTROLS Manual Supply port Port for line of work Exhaust Port for line of work Exhaust Pilot side that overrides the output signal sensitive ball-push roller lever elettric with manual uni-directional roller lever pneumatic amplified electric external supply port pneumatic spring foot valves pneumatic amplified bistable foot valves foot valves with security on control...

Open the catalog to page 6

>SI units - (multiples and sub-multiples) Quantity Meter Kilometer Square meter Square centimeter Cubic meter Cubic decimeter Second Minute Hour Meter/second Meter/minute Kilometer/hour Acceleration Flow rate Force Pressure Temperature Work-energy Meter/square second Cubic meter/second Cubic decimetres/minute Cubic meter/hour Newton Kilopound Pascal Bar Kilogram/square centimeter Tecnical atmosphere Kelvin Celsius Joule Kilogram-meter Watt-hour Kilowatt-hour Watt Kilogram-meter/second Horsepower Horsepower Electric current °C = °K - 273,15 1 kgm = 9.806 Joule 1 Wh = 3600 Joule 1 kwh = 3600....

Open the catalog to page 7

>Protection degrees for coil with connector By protection degree we mean the intrinsic ability of live electrical equipment to protect and to protect itself against casual contacts and penetration of solid perticles and water. It is defined with the abbreviation “I.P.” followed by 2 figures: the first, 0 to 6, defines the protection against casual contacts and penetration of particles; the second, 0 to 8, the protection against water. Protection degree against casual contacts and penetration of particles Protection/Denomination No special protection for people against casual contacts with...

Open the catalog to page 8

>Product table PNEUMOMECHANICAL SPRING MECHANICAL SPRING THREADS/SUB BASES FLOW RATE (Nl/min) NAMUR interface tube Ø4 tube Ø6 tube Ø8 FOOT VALVES * For AG valves the value refers to vacuum version (mm Hg)

Open the catalog to page 9

BIO 10 mm Nanovalves-hight flow rate 1.05

Open the catalog to page 11

B 10 mm nanovalves - Flow rate 12 Nl/min - Interface with conveyed discharge or discharge in the air - Versions 3/2 normally open (NO) and normally closed (NC) - Interchangeable coil (U04) - rotation by 180° - Molex-type electrical connector or louse wires TECHNICAL CHARACTERISTICS Ambient temperature Fluid temperature Fluid Commutation system Ways/Positions Pressure Control Return Connections Nominal Ø Nominal flow rate Max frequency Substructure -5 ÷ +50 °C max +50 °C 10 μm filtered air, lubricated or not poppet valve 3/2 NC, 3/2 NO max 8 bar electric mechanical spring on sub-base 0,5÷0,6...

Open the catalog to page 13

UNIVER GROUP Valves with conveyed discharge 1 = Supply port 2 = Use 3 = Exhaust A Manual override Symbol Flow rate Nl/min. Valves with discharge in the air 1 = Supply port 2 = Use 3 = Exhaust A Manual override Symbol U04 with integrated upward 90° connector U04 with in-line connector U04 with loose wires (300 mm lenght) U04 with in-line connector with protecting cover for complete tightness (a) = upon request: 0 bar operation (b) = the value in brackets indicates the mass with coil (0,015 Kg with 300 mm loose wires) For technical features of coils and connector, see section...

Open the catalog to page 14

B10 10 mm nanovalves ISO 15218 - Low input standard: 0,3 W - High flow-rate: 30 Nl/min - Quick response time: 3 ms - ISO 15218 interface - 3/2 NC version - Led standard Upon request: - Bistable version - 0,1 W version - 50 Nl/min flow rate version TECHNICAL CHARACTERISTICS Ambient temperature Fluid temperature Fluid Ways/Positions Pressure Control Return Operating frequency Assembly Connections Nominal Ø (mm) Nominal flow rate (Nl/min) -5 ÷ +50 °C max +50 °C 10 μm filtered air, lubricated or not 3/2 NC (monostable) 3/2 NC-NO (bistable) max 8 bar electric mechanical spring 5 Hz no. 2 screws...

Open the catalog to page 15

UNIVER GROUP 90° Connector without manual override 1 = Supply port 2 = Use 3 = Exhaust single connector with 3-5 m wire weight Kg: 0,05 D-535U40300 wire L = 300 mm 0,07 D-535U40500 wire L = 500 mm In-line PIN without manual override In-line PIN bistable (magnetic memory) In this version the opening is carried out by a 25 ms impulse, while the closing is carried out by a similar impulse with inverted polarity. For any further information please get in touch with our Sales Office. (a) = with manual override (b) = without manual override A Manual override 1 = Supply port 2 = Use 3 = Exh

Open the catalog to page 16All UNIVER Group catalogs and technical brochures

-

JLE

5 Pages

-

HZRS

2 Pages

-

MP Clamping cylinders

3 Pages

-

AC-N NAMUR valve

2 Pages

-

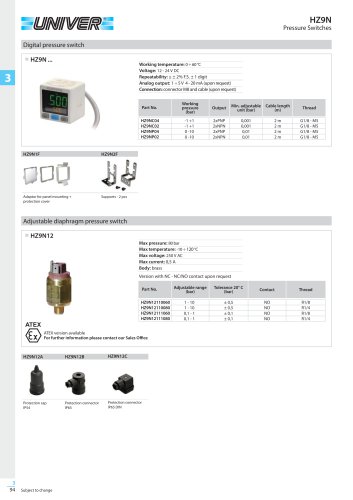

HZ9N

1 Pages

-

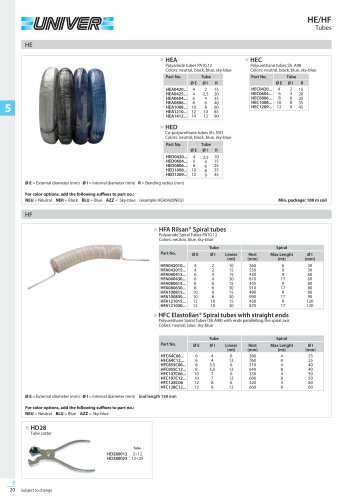

HE/HF tubes

1 Pages

-

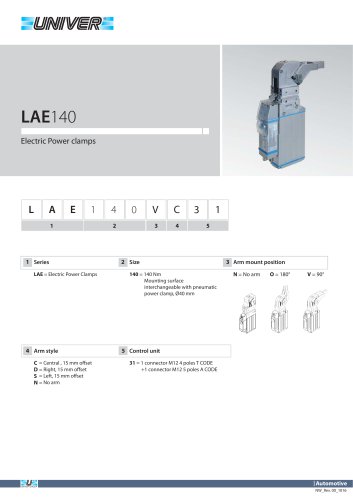

LAE140 Electric power clamps

4 Pages

-

Modular Tooling System - GR8

52 Pages

-

PRODUCT RANGE

44 Pages

-

ATEX PRODUCT RANGE

14 Pages

-

NEWS 2017-2018

32 Pages

-

NEWS 2016

16 Pages

-

PRODUCT OVERVIEW

228 Pages

-

Product range

44 Pages

-

ATEX Certified products

14 Pages

-

NEWS 2017

32 Pages

-

UBH40_UNIVERSAL Power clamps

6 Pages

-

PRODUCT RANGE

32 Pages

-

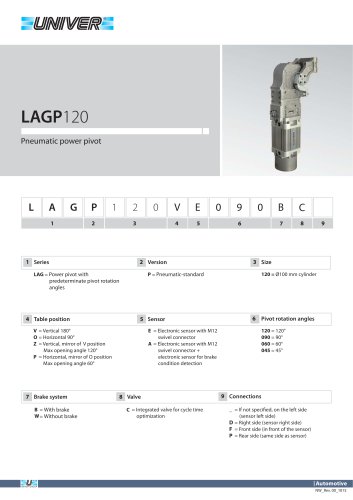

LAGP605_Pneumatic power pivot

13 Pages

-

LAGP600_Pneumatic power pivot

13 Pages

-

LAGP350_Pneumatic power pivot

13 Pages

-

LAGP300_Pneumatic power pivot

13 Pages

-

LAGP210_Pneumatic power pivot

13 Pages

-

LAGP170_Pneumatic power pivot

13 Pages

-

LAGP155_Pneumatic power pivot

13 Pages

-

LAGP150_Pneumatic power pivot

13 Pages

-

LAGP120_Pneumatic power pivot

13 Pages

-

LAGP080_Pneumatic power pivot

13 Pages

-

LAGP075_Pneumatic power pivot

13 Pages

-

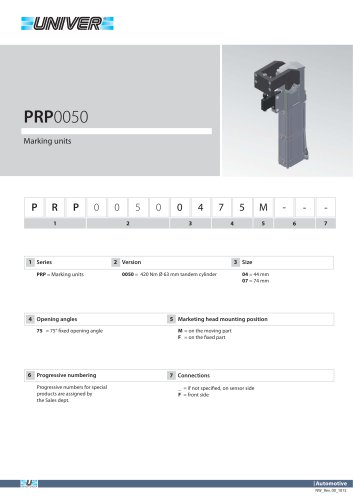

PRP1100_Marking units

3 Pages

-

PRP0500_Marking Units

4 Pages

-

PRP0050_Marking units

3 Pages

-

PRP0025_Marking units

2 Pages

-

LGP40_ Pneumatic Grippers

7 Pages

-

LGP32_ Pneumatic Grippers

7 Pages

-

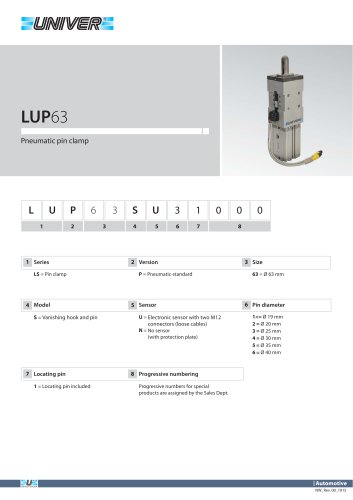

LUP63_Pneumatic pin clamp

2 Pages

-

LSP60_Pneumatic pin clamp

3 Pages

-

LSP50U_Pneumatic pin clamp

3 Pages

-

LSP32_Pneumatic pin clamp

3 Pages

-

IBM40_UNIVERSAL Power clamps

6 Pages

-

IBP40_UNIVERSAL Power clamps

6 Pages

-

UBH63_UNIVERSAL Power clamps

6 Pages

-

UBM40_UNIVERSAL Power clamps

6 Pages

-

UBM50_UNIVERSAL Power clamps

10 Pages

-

UBM63_UNIVERSAL Power clamps

10 Pages

-

UBM80_UNIVERSAL Power clamps

10 Pages

-

UBP32_UNIVERSAL Power clamps

4 Pages

-

UBP50_UNIVERSAL Power clamps

6 Pages

-

UBP63_UNIVERSAL Power clamps

6 Pages

-

UBP80_UNIVERSAL Power clamps

8 Pages

-

UBQ40_UNIVERSAL Power clamps

8 Pages

-

UBQ63_UNIVERSAL Power clamps

6 Pages

-

UBT40_UNIVERSAL Power clamps

6 Pages

-

AUTOMOTIVE DIVISION

24 Pages

-

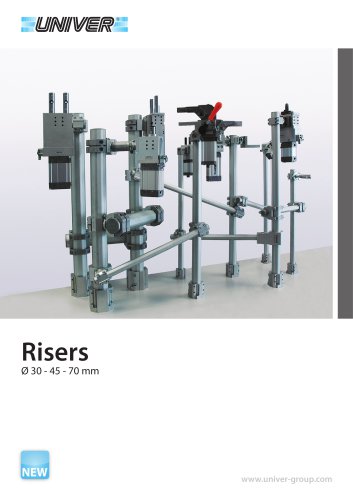

RISERS

4 Pages

-

LGP32-40 Pneumatic Grippers

16 Pages

-

GR8-Modular Tooling System

44 Pages

-

M series

1 Pages

-

Product Overview

228 Pages

-

POWER PIVOTS

2 Pages

-

PIN CLAMPS

2 Pages

-

CLAMPS

2 Pages

-

ACCESSORIES

54 Pages

-

AIR TREATMENT

14 Pages

-

HIGH TECH

75 Pages

-

CYLINDERS

67 Pages

-

KE_Cylinders according to ISO 15552

10 Pages

-

HZE_Additional components

4 Pages

-

HZE_Air treatment units

14 Pages

-

L1/L6_Locking unit for cylinders

6 Pages

-

HZE_Air treatment units

12 Pages

-

fittings

36 Pages

-

PS_COMBOBOX valves

12 Pages

-

AI_Miniature limit switches

4 Pages

-

CH_2/2 - 3/2 G1/8 poppet valves

4 Pages

-

A_15 mm Microvalves

6 Pages

-

B10_Nanovalvole 10 mm ISO 15218

2 Pages

-

OV_Oval cylinders Ø 18-80 mm

5 Pages

-

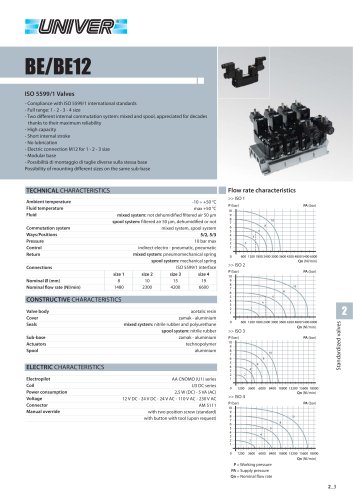

BE/BE12_ISO 5599/1 Valves

12 Pages

-

Rodless cylinders Ø 16-50 mm

12 Pages

-

Rotary actuators Ø 32-125 mm

3 Pages