Website:

UNIVER Group

Website:

UNIVER Group

Catalog excerpts

65-I Cylinders Cyl. Ø 2 4 6 8 10 18 Thrust 54 108 162 216 270 Traction 41 82 122 163 204 25 Thrust 98 196 295 393 491 Traction 82 165 247 330 412 32 Thrust 161 322 483 643 804 Traction 138 276 415 553 691 40 Thrust 251 502 754 1005 1256 Traction 221 422 633 844 1055 50 Thrust 393 785 1178 1570 1963 Traction 330 660 990 1320 1650 63 Thrust 623 1246 1870 2493 3116 Traction 560 1120 1682 2240 2800 80 Thrust 1005 2010 3015 4019 5024 Traction 942 1884 2826 3770 4711 Oval cylinders Ø 18 - 80 mm Compact oval cylinder with adjustable pneumatic cushioning and standard magnetic version; its special shape allows the assembly of several coupled cylinders with reduced overall dimensions (in width). Working pressure: 1,5 ÷ 10 bar Ambient temperature: -20C° ÷ 80°C Fluid: compressed air, lubricated or not. Barrel: extruded barrel in aluminium alloy, anodized externally and internally 15 ìm with profile for flushmounted sensor End-caps in aluminium. Self-threading screw in zinc-plated steel. Piston in aluminium. Piston seals in nitrile rubber. Rod seals in polyurethane. Adjustable pneumatic cushioning which allows an efficient TECHNICAL CHARACTERISTICS deceleration of the piston and reduces noise level. Piston rod in chromium-plated steel Ø 32 ÷ 80 mm, in stainless steel Ø 18 ÷ 25 mm. Magnetic version. Max. speed: 1 m/s With integrated fixing accessories: front, rear, lower and side. Executions upon request: - Versions with stainless steel rod (Ø 32 ÷ 80 mm) or in chromium-plated steel (Ø 18 ÷ 25 mm) - Magnetic sensor DF-...series. - Wire cover strap for magnetic sensor part n° DHF-002100. In case of pneumatic cylinders with through rod, theoretical force to be considered, in both direction, is always the same as the "traction" value indicated in the table. In practice these values will have to be reduced taking into account the weight and sliding friction of moving parts (approx. ~ -10%). Working pressure [bar] Theoretical forces (N) developed at the following working pressures (bar) 1 bar = 0,1 MPa Maximum applicable torque (Nm) and respective max. rotation Cyl Ø Nm (°) 18 0,80 0,90 25 1,00 0,80 32 1,40 0,60 40 1,70 0,40 50 2,00 0,35 63 2,30 0,30 80 2,60 0,30 Codification key Stroke Bore OV 200 050 0080 Type Series SERIES OV = Oval Cylinders Ø 18 ÷ 80 mm TYPE 1--- Female rod in stainless steel 2--- Female rod in chromium-plated steel (excluded Ø 18 - 25 mm) 3--- Male rod in stainless steel 4--- Male rod in chromium-plated steel (excluded Ø 18 - 25 mm) -00 D.A. -01 D.A. through rod -02 D.A. hollow through rod BORE 018 - 025 - 032 - 040 - 050 - 063 - 080 mm STROKE 0010-0025-0040-0050-0080-0100-0125-0160-0200 (Ø 18 ÷ 80 mm) 0250-0320 (Ø 32 ÷ 80 mm) Nominal tolerance on the stroke 18 ÷ 25 + 1,5/0 32 ÷ 50 + 2/0 63 ÷ 80 + 2,5/0 Cyl Tolerance Ø mm

Open the catalog to page 1All UNIVER Group catalogs and technical brochures

-

JLE

5 Pages

-

HZRS

2 Pages

-

MP Clamping cylinders

3 Pages

-

AC-N NAMUR valve

2 Pages

-

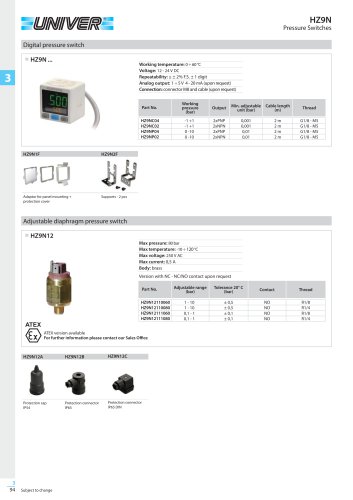

HZ9N

1 Pages

-

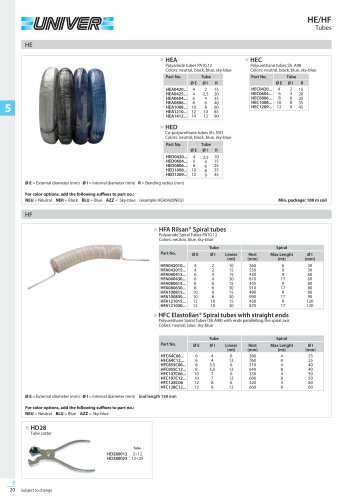

HE/HF tubes

1 Pages

-

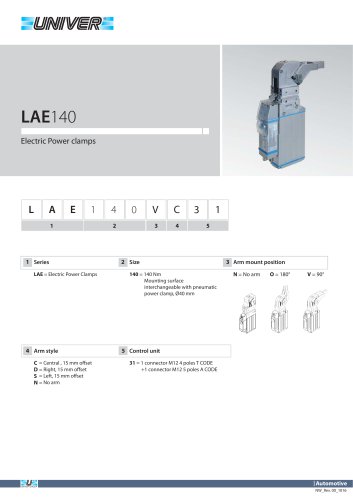

LAE140 Electric power clamps

4 Pages

-

Modular Tooling System - GR8

52 Pages

-

PRODUCT RANGE

44 Pages

-

ATEX PRODUCT RANGE

14 Pages

-

NEWS 2017-2018

32 Pages

-

NEWS 2016

16 Pages

-

PRODUCT OVERVIEW

228 Pages

-

Product range

44 Pages

-

ATEX Certified products

14 Pages

-

NEWS 2017

32 Pages

-

Valves

210 Pages

-

UBH40_UNIVERSAL Power clamps

6 Pages

-

PRODUCT RANGE

32 Pages

-

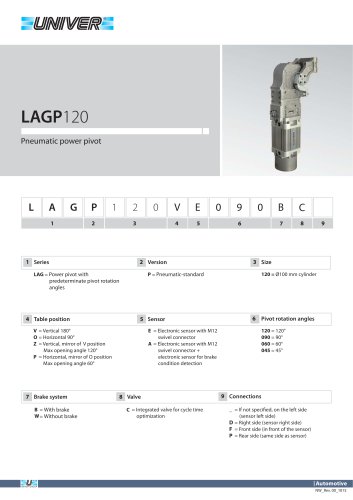

LAGP605_Pneumatic power pivot

13 Pages

-

LAGP600_Pneumatic power pivot

13 Pages

-

LAGP350_Pneumatic power pivot

13 Pages

-

LAGP300_Pneumatic power pivot

13 Pages

-

LAGP210_Pneumatic power pivot

13 Pages

-

LAGP170_Pneumatic power pivot

13 Pages

-

LAGP155_Pneumatic power pivot

13 Pages

-

LAGP150_Pneumatic power pivot

13 Pages

-

LAGP120_Pneumatic power pivot

13 Pages

-

LAGP080_Pneumatic power pivot

13 Pages

-

LAGP075_Pneumatic power pivot

13 Pages

-

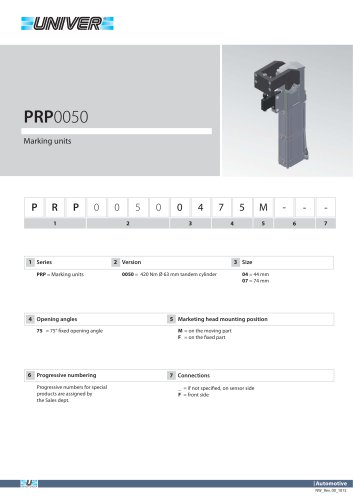

PRP1100_Marking units

3 Pages

-

PRP0500_Marking Units

4 Pages

-

PRP0050_Marking units

3 Pages

-

PRP0025_Marking units

2 Pages

-

LGP40_ Pneumatic Grippers

7 Pages

-

LGP32_ Pneumatic Grippers

7 Pages

-

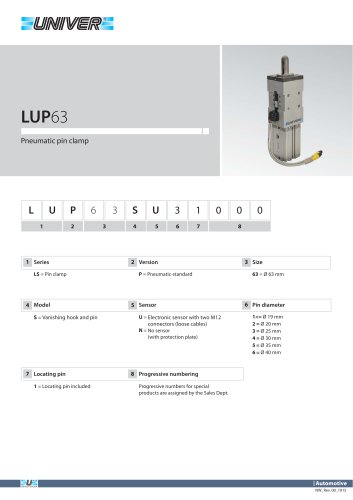

LUP63_Pneumatic pin clamp

2 Pages

-

LSP60_Pneumatic pin clamp

3 Pages

-

LSP50U_Pneumatic pin clamp

3 Pages

-

LSP32_Pneumatic pin clamp

3 Pages

-

IBM40_UNIVERSAL Power clamps

6 Pages

-

IBP40_UNIVERSAL Power clamps

6 Pages

-

UBH63_UNIVERSAL Power clamps

6 Pages

-

UBM40_UNIVERSAL Power clamps

6 Pages

-

UBM50_UNIVERSAL Power clamps

10 Pages

-

UBM63_UNIVERSAL Power clamps

10 Pages

-

UBM80_UNIVERSAL Power clamps

10 Pages

-

UBP32_UNIVERSAL Power clamps

4 Pages

-

UBP50_UNIVERSAL Power clamps

6 Pages

-

UBP63_UNIVERSAL Power clamps

6 Pages

-

UBP80_UNIVERSAL Power clamps

8 Pages

-

UBQ40_UNIVERSAL Power clamps

8 Pages

-

UBQ63_UNIVERSAL Power clamps

6 Pages

-

UBT40_UNIVERSAL Power clamps

6 Pages

-

AUTOMOTIVE DIVISION

24 Pages

-

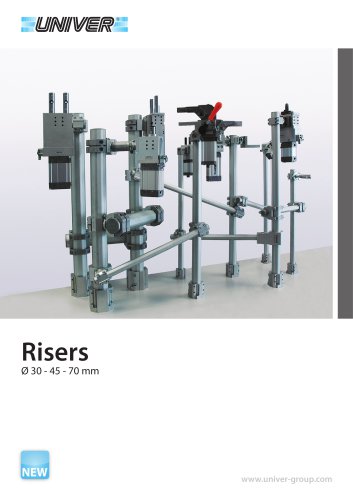

RISERS

4 Pages

-

LGP32-40 Pneumatic Grippers

16 Pages

-

GR8-Modular Tooling System

44 Pages

-

M series

1 Pages

-

Product Overview

228 Pages

-

POWER PIVOTS

2 Pages

-

PIN CLAMPS

2 Pages

-

CLAMPS

2 Pages

-

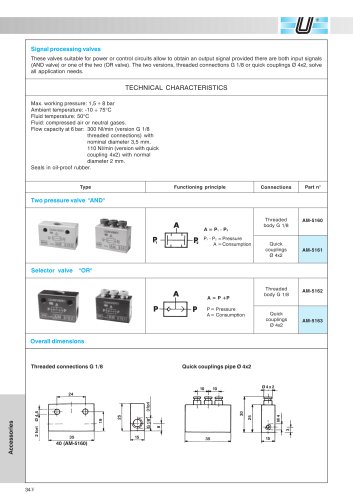

ACCESSORIES

54 Pages

-

AIR TREATMENT

14 Pages

-

HIGH TECH

75 Pages

-

CYLINDERS

67 Pages

-

KE_Cylinders according to ISO 15552

10 Pages

-

HZE_Additional components

4 Pages

-

HZE_Air treatment units

14 Pages

-

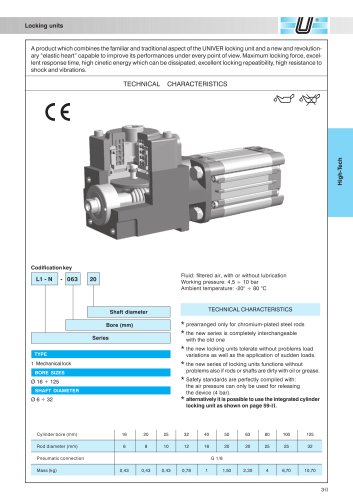

L1/L6_Locking unit for cylinders

6 Pages

-

HZE_Air treatment units

12 Pages

-

fittings

36 Pages

-

PS_COMBOBOX valves

12 Pages

-

AI_Miniature limit switches

4 Pages

-

CH_2/2 - 3/2 G1/8 poppet valves

4 Pages

-

A_15 mm Microvalves

6 Pages

-

B10_Nanovalvole 10 mm ISO 15218

2 Pages

-

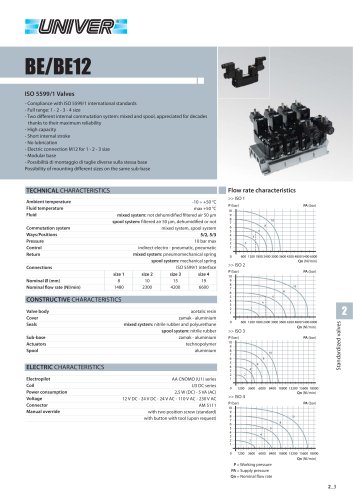

BE/BE12_ISO 5599/1 Valves

12 Pages

-

Rodless cylinders Ø 16-50 mm

12 Pages

-

Rotary actuators Ø 32-125 mm

3 Pages