Website:

UNIVER Group

Website:

UNIVER Group

Catalog excerpts

1_9 1 Electropilots Direct intervention electropilots with poppet valve system and cushioned bottom seals - Assembly on sub-base - Threaded connections on the body - CNOMO interface - Orientable coil (360°) separated from mechanical part - Versions: 2/2 3/2 NC - NO - Original Univer SPEED modular sub-bases Miniature electropilots U1 AA (a) = Mechanical part designed to keep the air supply always from the body (Useful in case of assembly of more NC-NO pilots in series to have a unique supply port) TECHNICAL CHARACTERISTICS Ambient temperature Fluid temperature Fluid Commutation system Ways/Positions Pressure Control Return Connections Nominal Ø (mm) Nominal fl ow rate (Nl/min) CONSTRUCTIVE CHARACTERISTICS Materials see features below ELECTRIC CHARACTERISTICS Series Coil Power consumption Connector Voltage Protection degree U1 U3 DA DC 12 V DC - 24 V DC - 24 V AC - 110 V AC - 230 V AC 3,5 W (DC) - 5 VA (AC) 2,5 W (DC) - 3,3 VA (AC) AM 5110 AM 5111 sub-base G 1/8 M5 CNOMO 1,2 ÷ 1,5 1 ÷ 1,5 1 ÷ 1,5 1,2 ÷ 1,5 30 ÷ 60 28 ÷ 60 30 ÷ 60 33 ÷ 45 -10 ÷ +50 °C max +95 °C 10 ìm fi ltered air, lubricated or not, neutral gases (upon request other fl uids can be used) direct intervention poppet valve system with cushioned seals 2/2 NC, 3/2 NC, 3/2 NO(a) 2/2, 3/2 NC = 0 ÷ 10 3/2 NO = 3 ÷ 10 electric mechanical spring on sub-base or with threaded connections on the body IP65 For other electric features see section “Accessories>Coils”

Open the catalog to page 1

UNIVER GROUP AA Miniature electropilots U1 1_10 (a) = Mounted on the 3/2 NO sleeve = with 2 position screw Locking rings for coils on sleeves In order to convey exhausts, use version 3 Version Suitable for sleeves 3/2 NO 3/2 NC 2/2 NC 1 = radial exhausts 2 = radial exhausts 3 = open exhausts Part no. AM-5213A AM-5211A AM-5211B Coil U1 U1 U1 Material technopolymer technopolymer brass Standard manual overrides Functionig 1 = with 2 position screw 2 = with impulse 1-2 position screw 3 = with button with tool 4 = with button, 1 position Suitable for sleeves Symbol/Part no. all NC U1...

Open the catalog to page 2

UNIVER GROUP AA Miniature electropilots U1 1 Electropilots 1_11 Material: valve body sleeve core and spring seals Weight (Kg): brass treated brass stainless steel nitrile rubber 0,065 U1 2/2 - 3/2 Electropilot for assembling on sub-base 3/2 NC 2/2 NC 3/2 NO Use SPEED subbase to build Manifolds, see following pages. Available upon request: brass valve body (without manual override), zamak valve body, stainless steel sleeve, other inner diameters. (b) AA-0184 AA-0186 AA-0188 Part no. 60 50 30 80 - 70 1 .. 2 2 .. 3 Flow rate (Nl/min) 12 16 11 12 - 10 En. Times (ms) De-en. (c) Manual override...

Open the catalog to page 3

UNIVER GROUP AA Miniature electropilots U1 1_12 U1 CNOMO 2/2 - 3/2 Electropilot for mounting on sub-bases SPEED U2 2/2 NC 3/2 NO (b) 3/2 NC Sub-base: SPEED U2. Available upon request: brass valve body (without manual override). Zamak valve body. Stainless steel sleeve - other inner diameters. .. (c) Manual override Ø (d) mm 1,3 1,2 1,5 1,5 1 2 42 33 - 77 77 77 45 45 .. 2 .. 3 Flow rate (Nl/min) AA-0402 AA-0404 Part no. AA-0400 AA-0400U - 11 - 10 12 12 12 12 En. De-en. Symbol Times (ms) Part no. AA-0450 AB-0900 Electropilot U1 for base U2 for base Connections G 1/8 G 1/8 Material zamak zamak...

Open the catalog to page 4

UNIVER GROUP AA Miniature electropilots U1 1 Electropilots 1_13 U1 G1/8 sub-base U2 G1/8 CNOMO sub-base A = Supply port = Use = Number of valve positions 1 2 N A Manual override A = Supply port = Use = Number of valve positions 1 2 - A N A Manual override

Open the catalog to page 5All UNIVER Group catalogs and technical brochures

-

JLE

5 Pages

-

HZRS

2 Pages

-

MP Clamping cylinders

3 Pages

-

AC-N NAMUR valve

2 Pages

-

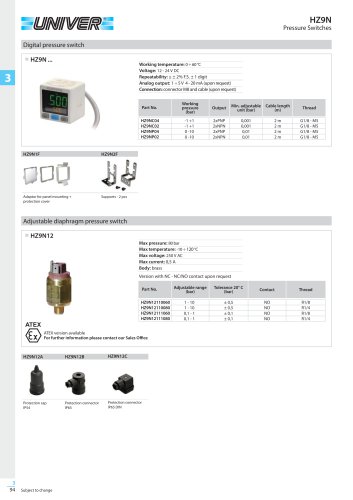

HZ9N

1 Pages

-

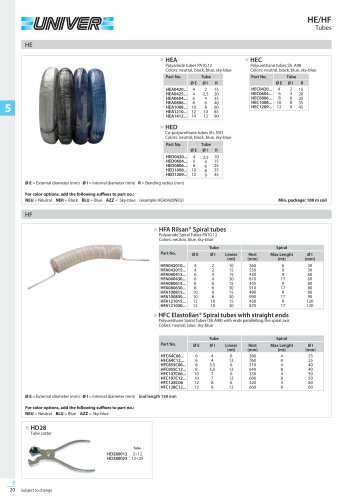

HE/HF tubes

1 Pages

-

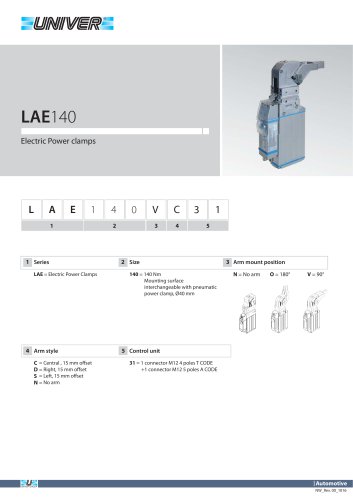

LAE140 Electric power clamps

4 Pages

-

Modular Tooling System - GR8

52 Pages

-

PRODUCT RANGE

44 Pages

-

ATEX PRODUCT RANGE

14 Pages

-

NEWS 2017-2018

32 Pages

-

NEWS 2016

16 Pages

-

PRODUCT OVERVIEW

228 Pages

-

Product range

44 Pages

-

ATEX Certified products

14 Pages

-

NEWS 2017

32 Pages

-

Valves

210 Pages

-

UBH40_UNIVERSAL Power clamps

6 Pages

-

PRODUCT RANGE

32 Pages

-

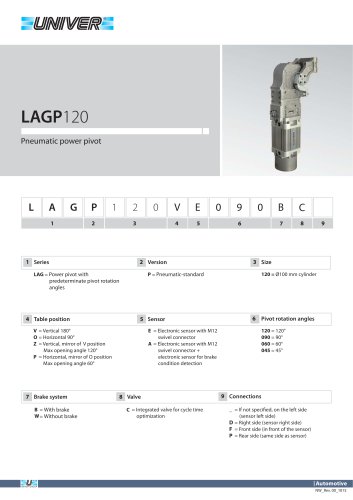

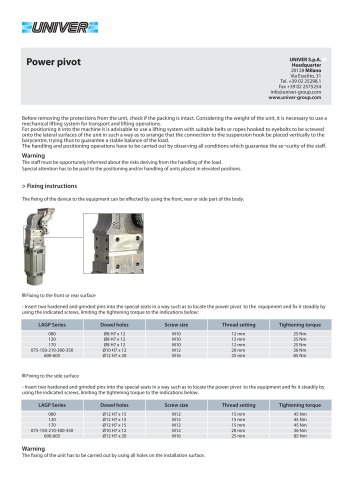

LAGP605_Pneumatic power pivot

13 Pages

-

LAGP600_Pneumatic power pivot

13 Pages

-

LAGP350_Pneumatic power pivot

13 Pages

-

LAGP300_Pneumatic power pivot

13 Pages

-

LAGP210_Pneumatic power pivot

13 Pages

-

LAGP170_Pneumatic power pivot

13 Pages

-

LAGP155_Pneumatic power pivot

13 Pages

-

LAGP150_Pneumatic power pivot

13 Pages

-

LAGP120_Pneumatic power pivot

13 Pages

-

LAGP080_Pneumatic power pivot

13 Pages

-

LAGP075_Pneumatic power pivot

13 Pages

-

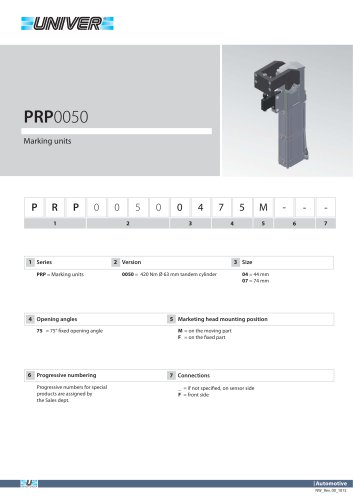

PRP1100_Marking units

3 Pages

-

PRP0500_Marking Units

4 Pages

-

PRP0050_Marking units

3 Pages

-

PRP0025_Marking units

2 Pages

-

LGP40_ Pneumatic Grippers

7 Pages

-

LGP32_ Pneumatic Grippers

7 Pages

-

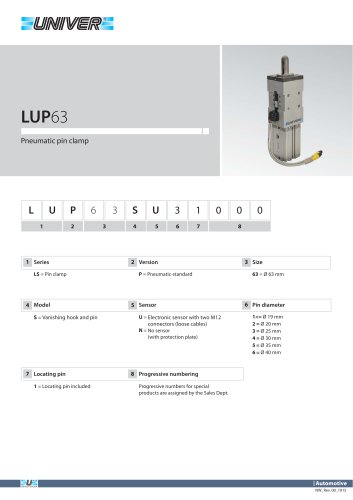

LUP63_Pneumatic pin clamp

2 Pages

-

LSP60_Pneumatic pin clamp

3 Pages

-

LSP50U_Pneumatic pin clamp

3 Pages

-

LSP32_Pneumatic pin clamp

3 Pages

-

IBM40_UNIVERSAL Power clamps

6 Pages

-

IBP40_UNIVERSAL Power clamps

6 Pages

-

UBH63_UNIVERSAL Power clamps

6 Pages

-

UBM40_UNIVERSAL Power clamps

6 Pages

-

UBM50_UNIVERSAL Power clamps

10 Pages

-

UBM63_UNIVERSAL Power clamps

10 Pages

-

UBM80_UNIVERSAL Power clamps

10 Pages

-

UBP32_UNIVERSAL Power clamps

4 Pages

-

UBP50_UNIVERSAL Power clamps

6 Pages

-

UBP63_UNIVERSAL Power clamps

6 Pages

-

UBP80_UNIVERSAL Power clamps

8 Pages

-

UBQ40_UNIVERSAL Power clamps

8 Pages

-

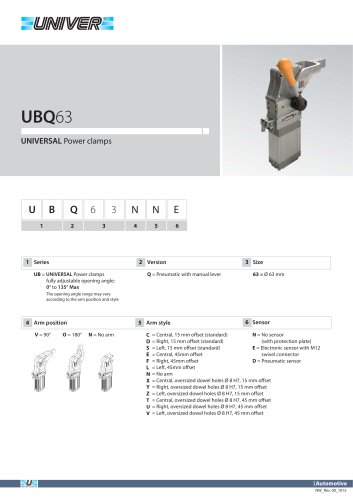

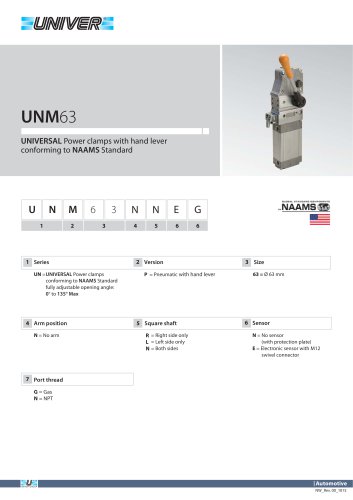

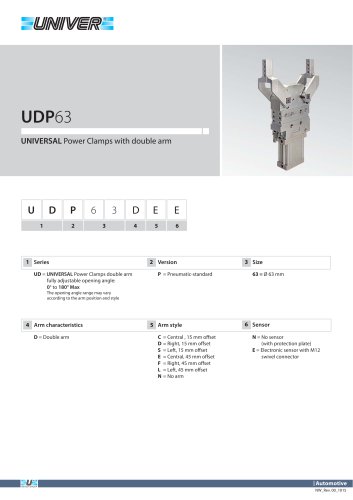

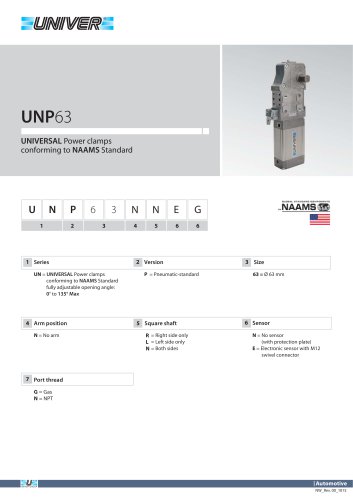

UBQ63_UNIVERSAL Power clamps

6 Pages

-

UBT40_UNIVERSAL Power clamps

6 Pages

-

AUTOMOTIVE DIVISION

24 Pages

-

RISERS

4 Pages

-

LGP32-40 Pneumatic Grippers

16 Pages

-

GR8-Modular Tooling System

44 Pages

-

M series

1 Pages

-

Product Overview

228 Pages

-

POWER PIVOTS

2 Pages

-

PIN CLAMPS

2 Pages

-

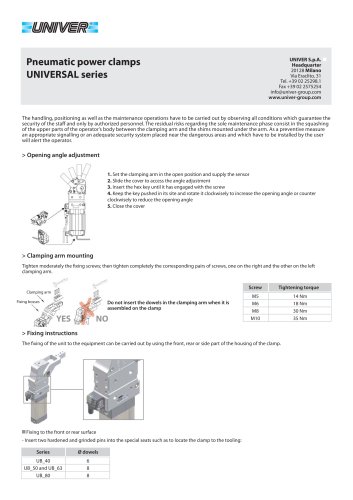

CLAMPS

2 Pages

-

ACCESSORIES

54 Pages

-

AIR TREATMENT

14 Pages

-

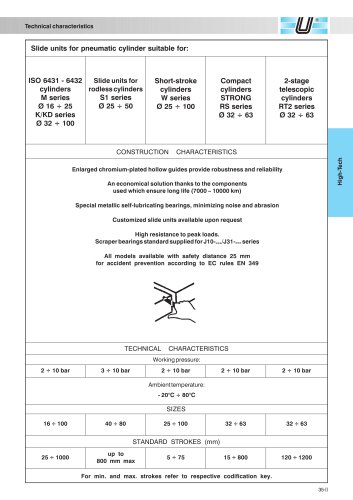

HIGH TECH

75 Pages

-

CYLINDERS

67 Pages

-

KE_Cylinders according to ISO 15552

10 Pages

-

HZE_Additional components

4 Pages

-

HZE_Air treatment units

14 Pages

-

L1/L6_Locking unit for cylinders

6 Pages

-

HZE_Air treatment units

12 Pages

-

fittings

36 Pages

-

PS_COMBOBOX valves

12 Pages

-

AI_Miniature limit switches

4 Pages

-

CH_2/2 - 3/2 G1/8 poppet valves

4 Pages

-

A_15 mm Microvalves

6 Pages

-

B10_Nanovalvole 10 mm ISO 15218

2 Pages

-

OV_Oval cylinders Ø 18-80 mm

5 Pages

-

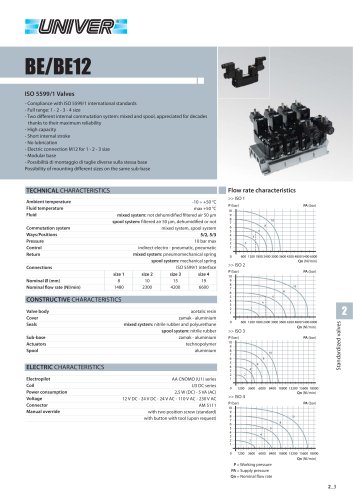

BE/BE12_ISO 5599/1 Valves

12 Pages

-

Rodless cylinders Ø 16-50 mm

12 Pages

-

Rotary actuators Ø 32-125 mm

3 Pages