Catalog excerpts

Filtration Specialist

Open the catalog to page 1

HOW DO WE WORK? ABOUT US Since 1996 we have specialized in the sole distribution of strainers, filtration equipment, industrial valves, and specific fluid control products from the best manufacturers on the market. We pride ourselves on our customized solutions, flexibility, and close communication with the customer. These qualities help us deal with our customers’ enquiries with maximum commitment and find the right solution to fit their business. This long journey has now also allowed us to be manufacturers of filters and pressure vessels. Our company is therefore orientated towards...

Open the catalog to page 2

TECHNICAL DEPARTMENT We are focused on meeting your specific needs, a quality which can be summed up in two words: FLEXIBILITY AND ADAPTABILITY. Our engineers’ work is fundamentally grounded in technical competency and diligent supervision of the manufacturing process. The best guarantee for the work we carry out in our technical department is the efficiency of our staff, who are equipped to implement a variety of engineering applications: PREPARATION AND SUPERVISION OF METALWORKS MECHANICAL DESIGN, CONSTRUCTION PLANS FOR FILTERS AND PRESSURE VESSELS DESIGNING MECHANICAL PARTS ENGINEERING...

Open the catalog to page 3

MANUFACTURING Our factory is located in the Berguedà region (Catalonia), close to the Llobregat river, an area with a long industrial history where the first textile communities in the province of Barcelona were born. It is an area that continues to stand out for its innovative mindset and its exposure to the world, which it has achieved by benefitting from the location’s unique characteristics. We are approved by ISO standard 9001:2015 and we are CE marked according to PED. Any stage of the manufacturing process is open to inspection. We are very flexible and have a great capacity to adapt...

Open the catalog to page 4

QUALITY We make sure we comply with quality standards for the manufacturing process of filters and pressure vessels which are developed in line with ISO Standard 9001:2015, from the proposal to delivery and the guarantee. The quality control activities are demonstrated in the Inspection Point Programme (Quality Plan) coordinated with the customer. The customer, or their representative, are invited to attend trials and tests of our equipment. Our welders are qualified in the procedures they carry out in every job, in compliance with ASME IX. The NDT operators and inspectors hold the...

Open the catalog to page 5

PRODUCT RANGE Main equipment protection. Quality in the pipeline process.

Open the catalog to page 6

B A S K E T F I LT E R Basket filters offer a higher filtration capacity compared to Y and temporary filters. Allow for easier cleaning, especially in sizes greater than 12” (DN 300). High capacity with reduced pressure loss in gas and liquid filtration, increasing intervals between maintenance. We provide high mechanical quality internals (baskets). SIZES FROM 1/2” TO 36” (DN 15 TO DN 900) RATING FROM 150# TO 2500# (PN 6 TO PN 420) Optimized bodies, designed to withstand high flow and low pressure drop. With optional quick-open mechanism. Cast and/or custom steel-welded according to...

Open the catalog to page 7

Y, TEE and CONICAL STRAINERS Y STRAINER They are the most common and economical strainers for permanent filtering of liquids, steam and gases. Ideal for applications where the fluid does not have large concentrations of solid particles. Full range of Y strainers in stock and manufacturing to order. To avoid problems derived from pressure drop generated in existing low-cost Y strainers, our Y strainers have wider bodies and greater filtration surface. TEMPORARY STRAINER (CONE AND TEE STRAINERS) Cone and Tee strainers are temporary strainers to eliminate large solids during short periods of...

Open the catalog to page 8

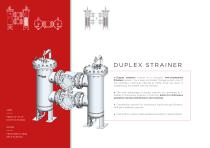

DUPLEX STRAINER Duplex strainers consist of a compact, two-chambered filtration system. Via a lever-controlled change system one of the chambers continues filtering at 100% while the other is isolated and the basket may be cleaned. The main advantage of duplex strainers as compared to Y, basket or temporary strainers is that they allow for continuous operation during maintenance and cleaning. Competitive solution for continuous liquid and gas filtration. Multiple installation options. SIZES Cast and/or custom steel-welded according to specifications. FROM 1/2” TO 24" (DN 15 TO DN 600)

Open the catalog to page 9

SELF- C LEA N I N G F I LTE RS Automatic filtration appropriate for demanding applications: high temperatures, filtration grades up to 25 microns, viscous products, tar, paper pulp, etc. Backflushing type The recipient contains various cartridges that filter from inside out. An electric motor operates a rotating arm that successively connects each cartridge with the backflush line, generating counterpressure in the cartridge from outside in. Particles are dragged out and flushed through the backflush line. While this is occurring in one cartridge, the rest continue filtering. Continuous...

Open the catalog to page 10

C A R T R I D G E F I LT E R S (LIQUIDS AND GASES) Cartridge filters are used to remove small solid particles from gases and liquids. Filtration grades from 1 micron (0,001 mm) and 99.9% removal efficiency. Custom designs according to requirements for flow, load of solids in suspension, pressure loss, etc. with backwashing solutions as an option. Safety interlock opening option for dangerous fluids or high pressure services. Reusable, long-lasting ceramic or metallic filtration elements; or disposable ones such as bag, membrane, cellulose, etc. SIZES FROM 1/2” TO 24” (DN 15 TO DN 600)...

Open the catalog to page 11

COA L E S C E R S Consist of Liquid-Liquid and Liquid-Gas phase separators: The fluid passes over a bed with graduated porosity to coalesce the particles from their initial microscopic size until they form droplets that detach due to gravity. If the density of the fluid to be separated is greater than the carrier medium, the collector is located in the lower part of the filter body. If not, the collection chamber is located in the upper part of the body. Their excellent performance in separation and filtration (99.9%) and their flow-adaptable capacity make coalescers ideal for many...

Open the catalog to page 12All Unitecno catalogs and technical brochures

-

Unitecno product

2 Pages