Catalog excerpts

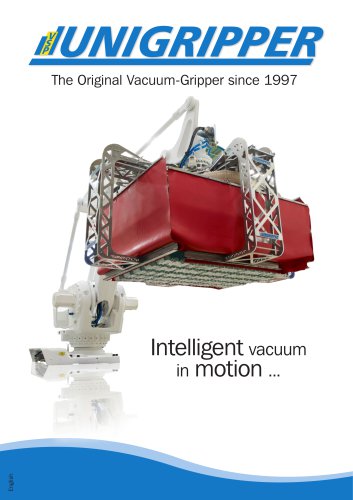

The Original Vacuum-Gripper since 1997 Intelligent vacuum in motion ...

Open the catalog to page 1

A Swedish Success Story UniGripper – The Strength comes from the Inside When Tepro Machine & Pac System AB delivered the first UniGrippers in the year 1997, and thereafter released the official UniGripper products to the world market, nobody expected that the technology based on the patented valve technology would be so versatile that we could expand our line of business from picking full layers of open jars to almost any product. We evolved from offering simple tools to supply complete solutions to the most challenging product handling tasks. Our biggest asset and advantage over our...

Open the catalog to page 2

Certified Quality UniGripper Tools are known for being the benchmark, not only in regards to the innovative nature of the solutions found by our qualified technicians, but also because of the high standard of our production and assembly. Our reputation allows us to produce for the Pharma, Food and Automotive Industry; including FDA regulated environments and even produce silicone free tools. Our unique modus operandi makes it possible to trace every delivered project throughout its life cycle, from the initial contact and budgetary offer to the final test in our factory. Maybe the fact that...

Open the catalog to page 3

Our standard module system was presented to the market in the beginning of this century as a response to the growing demand of a standard UniGripper. It has the same versatility as the UniGripper Customized as it is based on the same patented valve technology. The SMS Modules can be ordered with pneumatic vacuum generator or prepared for an electric source of vacuum. Another advantage is that we have the components of our Standard Module System in stock, ensuring a short lead time for spare parts. Each UniGripper, and therefore the Standard Module as well, has a foam carrier plate. This...

Open the catalog to page 4

The model range of our Standard Module System consists of 48 models, all kept in stock with their respective spare parts. Special lengths of up to 6 meters are available Additionally, the Standard Modules are used in many occasions as a side gripper for our classic series. Even our Standard Module System turns out to be a fully customizable and capable vacuum gripper, both as a stand-alone unit or integrated into other more complex systems. SMS type no. explanation

Open the catalog to page 5

UniGripper Customized The UniGripper Customized is our core business. Being the benchmark in Vacuum Gripping, UniGripper Customized stands for our core values as well. Versatile. Reliable. Customized. Used for palletizing, de-palletizing and even pick and place applications. Able to handle stones, bags, boxes, glasses, cans and many more products Whether the products are presented in open or closed trays, shrink wrapped or no wrap, whatever the task, there is a UniGripper to outperform your expectations. 100% customized to each project, we build the UniGripper Customized to our well proven...

Open the catalog to page 6

Original Vacuum-Gripper Available in any imaginary size, the build-up of any UniGripper is the same: The top plate, usually including some of the many accessories available, a frame and the valve plate containing the outstanding patented valves. The main spare part for any UniGripper is the foam. Ease of maintenance is granted as the foam is glued on a foam carrier plate, which enables you to change the foam within matters of minutes. The foam is available in different thicknesses and types, tailored for different applications, including automotive (silicone free) and FDA regulated...

Open the catalog to page 7

Many options Available for Optimal Each UniGripper can be customized according to each task to perform. From slip sheet picking to pallet handling, from cleaning the products to gluing, there is an accessory available for each task of the UniGripper. Exchangeable Foam Carrier Plate Emergency Sensors Pressure Regulator Layer Search Sensor Last but not least we are able to customize every component of the UniGripper, from pneumatics to electrics. Tilt Function Robot Adapter Valve Terminal Communication Device Mechanical Pallet Search Separation Function For detailed information, please visit...

Open the catalog to page 8

Tool-performance… Product Sensors Through the Gripper The most common tasks to be added to an UniGripper are the pallet and slip sheet handling as well as the division into different pick and release areas. Floating Attachment Side Clamping Bars Multi-Chamber Version These divisions allows the UniGripper to pick an entire row of products and place them individually. Pallet Hooks The most basic however is the source of vacuum. Either venturi style vacuum generators or side channel blowers are used to create the vacuum. We select the best power supply for each project. Sensor for Gripping...

Open the catalog to page 9

TimberGripper Wood and Furniture The TimberGripper was developed by UniGripper as an answer for the need of handling wood in rough environments. Equipped with additional dust filters, a specially designed valve system as well as the more enhanced design ensure that the TimberGripper outperforms any competitor on the market. In wood-working industries such as saw mills, manuacturing facilities and assemf bly lines, the TimberGripper is the choice to go for when reli bility, ease of maintenance a and perform nce are the requirements of a a successful operation. Transferring and handling...

Open the catalog to page 10

- Handling The furniture industry is another area where the TimberGripper is used, depending on the amount of dust which is found in the environment. TimberGripper is also superior in handling materials, with milled out grooves or holes. Thanks to our valve technology, the UniGripper series is the only vacuum gripper which can be used safely on turning tables. Furthermore the option to move MDF and similar porous sheets avoiding multiple unwanted picks makes us the number one in this branch as well. Our latest innovation is the spreading function, where the UniGripper is able to separate...

Open the catalog to page 11

Transferring entire layers is never an easy task. This is where the UniGripper Layer-Gripper really stands out and outperforms other solutions. The LayerGripper is available in several different editions, depending not only on the type of products but also how many different types of products the LayerGripper has to be able to master. Almost all LayerGrippers are equipped with the floating attachment, and, depending on the products to handle, side clamps with or without side skirts. nmkML LayerGrippers are available in many pallet sizes, from Euro- to Chep-, from Industrial-to US-Pallets....

Open the catalog to page 12All UniGripper catalogs and technical brochures

-

Intelligent Vacuum

21 Pages

-

Industry Solutions

24 Pages