Catalog excerpts

Intelligent Vacuum Industry Solutions

Open the catalog to page 1

Industry Solutions UniGrippers are used in almost all industries imaginable - from handling of sensitive medical equipment to boxes on open-sea fishing boats and packages of money at national banks. These grippers all have in common that they are based on the UniGripper Customized concept, which is further described on the next pages. The UniGripper customized concept is easily adaptable to any kind of industry. The table of contents to the right list handling scenarios which are the most common for us at UniGripper, but every day is a variation of these scenarios and new ones. A key for...

Open the catalog to page 2

UniGripper UniGripper Customized Accessories Vacuum Generation Partial Layer Handling Full Layer Handling Jar and Bottle Handling Bag Handling Timber and Wood handling Other Handling www.unigripper.com

Open the catalog to page 3

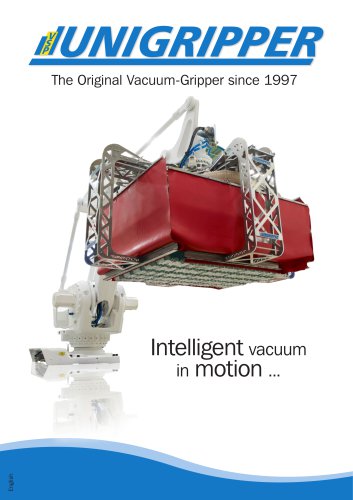

UniGripper has been a success story since the first grippers based on the Intelligent Vacuum technology were launched in the mid-1990s. Through continuous innovation for more than 20 years, UniGripper continues to be the natural choice for automation projects all over the world and for all kinds of industries. Our core values are Flexibility, Experience, Quality, Maintainability, Optimization and Partnership. Flexibility UniGripper has been associated with flexibility all the way since first being showcased. The UniGripper valves makes the gripper surface able to focus the vacuum flow to...

Open the catalog to page 4

Quality Core values of quality for UniGripper are high performance, fast delivery, reliability in operation and easy maintenance. UniGripper assures quality in all components such as spare parts with long life time. With tools delivered more than 20 years ago still in full use, we are confident that a customized UniGripper is a sustainable investment that will be part of your success for many years. Maintainability A vital success of a tool is the runtime. When we design a UniGripper we use components of highest quality in order to reduce the level of maintenance to a minimum. Our focus is...

Open the catalog to page 5

ToolingBoxes Accessorize Quality Gantry Customized um Industrial Foam cu Applications Standard Va Gripper Palletizing Glass Specialized Blower Most automation projects are unique to some degree. Anything from size constraints at the location of installation to specific properties or combination of products make one handling scenario different from another. UniGripper’s answer to this variation is UniGripper Customized. Function Guaranteed UniGripper Customized combines decades of experience of what is the optimal solution for every project with an efficient way-of-working for designing and...

Open the catalog to page 6

Customizing the Unigripper base Below are the main parameters that are customized in the UniGripper base plate. Selecting the right configuration for all parameters ensures a good function that lasts for many years and minimum maintenance needed. Valve Design Valve Pitch Outer Dimensions Large enough to get a secure grip of all products to be lifted. Small enough to avoid collisions with other equipment or fitting into boxes or other containers. Selected carefully to get a good distribution of vacuum force and securing enough active valves also on the smallest objects to be handled. The...

Open the catalog to page 7

AcCessories Input module Robot adapter Attachment Slip sheets ksSensors Terminal hooTubing Valves lletFloating Cylinders Rails PaSide clamps Side clamps Swivels Communication UniGrippers can be customized with a multitude of different accessories to increase the versatility of the tool and make the integration and implementation of a project as quick and easy as possible. The accessories range from function to improve the vacuum performance, to functions that add additional handling capabilities of for example pallets and slip-sheets, to control mechanisms like valve and input terminals...

Open the catalog to page 8

Floating Attachment Helps getting an optimal picking position and foam pad compression also when products or layers are tilted or vertical height is not exactly known. Slip-Sheet Handling Suction cups for slip-sheet handling in several variant to move the suction cups out of the way when not used. Search Foot Helps finding the height of a pallet in de-palletizing operations when vision systems or other methods for height detection is not available. Robot Spacer For extra space between the gripper and the robot arm for increased flexibility in robot movements. Solenoid Valves and Input...

Open the catalog to page 9

Vacuum Generation Blow e Filters Frequency Venturi Hose Tubes Energy Blowers Efficiency sFlow rRelief valves o ctReverse je ESilent Power Air Side-Channel Swivels Ejectors Ejectors are vacuum pumps generating vacuum using compressed air and the Venturi principle. Ejectors benefit from being easy to install as well as having lower investment cost for small to mid-size gripper, provided a compressor is already available in the factory. UniGripper ejectors are assembled into housings in three different sizes, which in turn can be configured with one or more active Venturi cartridges. When...

Open the catalog to page 10

Side Channel Blowers Side channel blowers use a fan wheel to remove air from the inlet and push the air out at the exhaust, thus creating vacuum in a gripper connected to the inlet. Compared to other blower kinds, side channel blowers are cost-effective blowers that generate high vacuum flows from atmospheric pressure to medium-deep vacuum levels, which is the ideal depth for most gripper applications. UniGripper works with leading manufacturers of side channel blowers to provide high quality blowers in different sizes depending on application. Side channel blowers are mainly beneficial for...

Open the catalog to page 11

Partial Layer Handling Slip-Sheets Shrink-Wrapps Efficient ZonesQuick Pick'n'Place Chambers Palletizing using vacuum grippers provides a storageand cost-effective solution for creating pallet patterns for different products at the same time and same place as palletizing is achieved. Grippers can be designed to handle anything from single cases to semi layers. By dividing the gripper into zones, vacuum can be applied at some areas of the gripper surface while other parts are inactive. Such solutions caters for optimized cycles as the gripper can pick a full row of cases and the release them...

Open the catalog to page 12All UniGripper catalogs and technical brochures

-

The UniGripper 2013 brochure

16 Pages

-

Intelligent Vacuum

21 Pages