Website:

Uniflex-Hydraulik GmbH

Website:

Uniflex-Hydraulik GmbH

Catalog excerpts

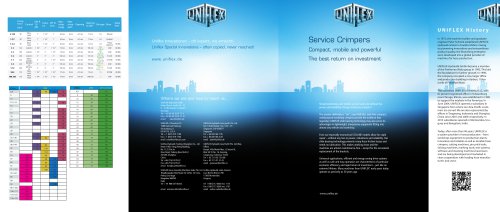

Main Catalog The Best Return on Investment

Open the catalog to page 1

UNIFLEX hose crimpers with the proven IPC Control system are setting standards for quality, cost effectiveness and ergonomic operations. UNIFLEX: 50 years on the road to the future Customer requirements with a focus on technology and services UNIFLEX-Hydraulik GmbH was founded in Frankfurt am Main in 1972. Thanks to the pioneering innovations and the extraordinary product quality, the flourishing company rapidly developed into one of the worldwide leading suppliers of machines for the production of hose assemblies. Innovation and sustainability in hose processing UNIFLEX-Hydraulik GmbH has...

Open the catalog to page 2

The machine manufacturing plant Utmost care for highest quality At UNIFLEX, there are no production lines and there is no mass production. The hose crimpers and all other devices and machines are produced in line with classical manufacturing processes, by hand and mostly only to order. Everybody is talking about digital transformation, and UNIFLEX takes action – for a long time already. In order to be able to offer all UNIFLEX customers innovative, computer-controlled devices, the company has developed the UNIFLEX Wireless Management System (UWMS) subsequent to the Control.2 system that has...

Open the catalog to page 3

Page 05-30 Service Crimpers Page 31-58 Production Crimpers We want to be the partner who supports all customers with “half a century of experience”. This philosophy drives us to meet the highest customer expectations as regards to quality and service, to continually enhance our internal processes and to design them with greater transparency for all. Our impetus is the will to create solutions. Therefore, we listen and cooperate as a prudent partner to ensure our quality and service are unparalleled. Hence, staff members at UNIFLEX are especially motivated, because they are ambitious to have...

Open the catalog to page 4

Service Crimpers Compact, universal and powerful.

Open the catalog to page 5

Service Crimpers • No greasing improves cleanliness of machine • Prolongs the machine‘s lifetime • Maximum productivity with very low maintenance costs • No risk of prematurely damaging the crimping head • End product can be used in sanitary applications without cleaning • 20% more capability for crimping stronger or more difficult couplings versus our competition’s equivalent crimpers • Consistently accurate crimp result • Slide bearings on the crimp tool improve efficiency up to 20%, reduce friction and help keep the tool free of contaminants Universal • For all types of hoses and...

Open the catalog to page 6

Front view Compact Light weight Good value Well suited for Factory warranty in years Service Crimpers

Open the catalog to page 7

SL 3 Next-generation crimper for low pressure hose assemblies. Two-in-one solution with integrated die sets O5 and O15 for DN 03-16. With the SL 3-16 M, UNIFLEX innovates the existing crimper: Two integrated die sets in one tool. No more lost time changing the die. Just change the handle and you are already crimping the other size. No risk of losing dies, no dirty hands, no “time lost”. With the built-in handle, you can easily carry it anywhere. SL 3-32 M and SL 3-75 complete the range with large opening travel up to 3". Service Crimpers

Open the catalog to page 8

Technical Data ** With master dies. Dies 150: 6.9 mm and 14.9 mm. Description Service Crimpers 09

Open the catalog to page 9

SH 2 (S 2) Must workshops and mobile service teams do without the power and reliability of large stationary crimpers? UNIFLEX‘s answer is a definite “no“. Our compact, multi-purpose workshop crimpers prove that the advantages of the legendary slide bearing technology can also be used in light-weight, inexpensive equipment that will fit into almost any vehicle and workshop. The SH 2 series models offer an optimal force-to-weight ratio of 1" 4 SP at a weight of 29 kg, a large opening stroke up to 22 mm (0.87") and a maximum pressing range up to 63 mm (2.48"). Service Crimpers

Open the catalog to page 10

Technical Data Speed (mm/sec) Close Crimp Drive * According to the fitting. ** With master dies. *** 7 bar/98 psi. Packages page 28 / Accessories and options page 56 Description Service Crimpers 11

Open the catalog to page 11

HM 200 As the unrivaled classic in the 1" field, with its narrow, innovative construction, high level of user friendliness, versatility and long service life, the HM 200 sets the unbeatable standard for quality and cost effectiveness. Its compact construction allows for ergonomic working. The use of different die sets allows pressing of all types of fittings, and the proven greaseless slide bearing technology reduces maintenance costs. The Ecoline model is hydraulically controlled and has a separate tank to save space in workshops. Service Crimpers

Open the catalog to page 12

HM 200 | HM 200 Ecoline Technical Data Bigg HM 200 HM 200 Ecoline Technical Data * According to the fitting. Packages page 28 / Accessories and options page 56 SC = Press tool with Cylinder Description The micrometer allows you to easily set the crimping diameter. The large opening stroke allows you to pass 90° fittings without changing the crimp dies. The 12 VDC/24 VDC units offer space- and weightsaving application options, e.g. for fitting service trucks. L x W x H (mm) A box with master dies is available in a package. For mobile applications the HM 200 is also ideally suitable.

Open the catalog to page 13

SC 3 (S 3) | SC 4 (S 4) Due to their narrow and innovative construction, high level of user friendliness and long service life, the SC 3 and SC 4 set new standards for quality and cost effectiveness. Their compact construction allows for ergonomic working. The use of long master dies allows you to crimp 90° elbow fittings up to 1 ¼" for SC 3 and 1 ½" for SC 4, with the tried and tested greaseless slide bearing technology, which reduces maintenance costs and increases the product quality. Because the 4-cylinder technology keeps press waste away from the die, UNIFLEX offers a 3-year warranty...

Open the catalog to page 14

Technical Data * According to the fitting. Packages page 28 / Accessories and options page 56 SC = Press tool with Cylinder Description The SC 3- and SC 4-series is fitted with the clean slide bearing technology. The SC 3- and SC 4-series can be used to crimp short 90° elbow fittings with a long drop. This is impossible for other conventional machines. With the double pin connection, it is possible to crimp on the front and rear sides. The 12 VDC/24 VDC units offer space- and weightsaving application options, e.g. for fitting service trucks. L x W x H [mm 441 x 291 x 296; 21 kg PB 239-MD-0...

Open the catalog to page 15All Uniflex-Hydraulik GmbH catalogs and technical brochures

-

Image Catalog 2023

28 Pages

-

Test Benches & Cleaning Machines

10 Pages

-

Special Equipment

8 Pages

-

Cutting machines

20 Pages

-

Main catalogue

116 Pages

-

Production Crimper

28 Pages

-

HM660_HM665_HM1200

2 Pages

-

HM450_HM480_HM495

2 Pages

-

HM3H

2 Pages

-

HM325_HM375_HM380

2 Pages

-

HM220_HM225

2 Pages

-

Option and Accessories

10 Pages

-

Catalogue

60 Pages

Archived catalogs

-

2020 Service Crimpers

23 Pages

-

2016 Service Crimpers

15 Pages

-

Product Overview

8 Pages

-

General Catalogue

34 Pages