Website:

Uniflex-Hydraulik GmbH

Website:

Uniflex-Hydraulik GmbH

Catalog excerpts

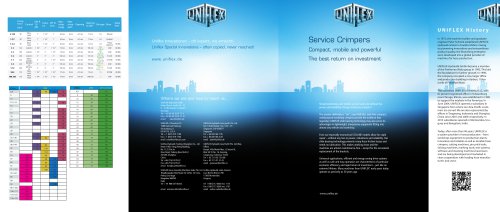

Main Catalog The Best Return on Investment

Open the catalog to page 1

UNIFLEX hose crimpers with the proven Control C.2 system are setting standards for quality, cost effectiveness and ergonomic operations. UNIFLEX: 50 years on the road to the future Customer requirements with a focus on technology and services UNIFLEX-Hydraulik GmbH was founded in Frankfurt am Main in 1972. Thanks to the pioneering innovations and the extraordinary product quality, the flourishing company rapidly developed into one of the worldwide leading suppliers of machines for the production of hose assemblies. Innovation and sustainability in hose processing UNIFLEX-Hydraulik GmbH has...

Open the catalog to page 2

The machine manufacturing plant Utmost care for highest quality At UNIFLEX, there are no production lines and there is no mass production. The hose crimpers and all other devices and machines are produced in line with classical manufacturing processes, by hand and mostly only to order. Everybody is talking about digital transformation, and UNIFLEX takes action – for a long time already. In order to be able to offer all UNIFLEX customers innovative, computer-controlled devices, the company has developed the UNIFLEX Wireless Management System (UWMS) subsequent to the Control.2 system that has...

Open the catalog to page 3

The best Return on Investment Sustainability pays off Hydraulic crimpers with slide bearing technology from UNIFLEX are offering a Return on Investment that is second to none. Profitability, sustainability and climate protection with a different approach: • The cost of exchanging slide bearings, oil, springs as well as a refurbish every 2 years for a life cycle of 23 years amounts to approximately € 14,000. Added to a machine price of € 20,000, this results in total costs of € 34,000 for 16,000,000 crimping processes. It`s logical: Whoever wants to work economically and wishes to save money...

Open the catalog to page 4

Objectives and vision We want to be the partner who supports all customers with “half a century of experience”. “We are only satisfied when our customers` customers are satisfied.” This philosophy drives us to meet the highest customer expectations as regards to quality and service, to continually enhance our internal processes and to design them with greater transparency for all. Our impetus is the will to create solutions. Therefore, we listen and cooperate as a prudent partner to ensure our quality and service are unparalleled. Patrick Sticker Managing Director / President Hence, staff...

Open the catalog to page 5

Page 07-32 Service Crimpers Page 33-60 Production Crimpers Page 61-80 Cutting Machines Page 81-94 Marking-, Bending Machines, Nipple Inserter, Pin Prick, Skiving Machines Page 95-104 Test Benches & Cleaning Machines Page 105-112 Special Equipment Page 113-23 Training – UX Inside

Open the catalog to page 6

Service Crimpers Compact, universal and powerful.

Open the catalog to page 7

Service Crimpers • No greasing improves cleanliness of machine • Prolongs the machine‘s lifetime • Maximum productivity with very low maintenance costs • No risk of prematurely damaging the crimping head • End product can be used in sanitary applications without cleaning • 20% more capability for crimping stronger or more difficult couplings versus our competition’s equivalent crimpers • Consistently accurate crimp result Page 18-19 SH 4 (S 3L Ecoline) Page 20-21 SH 7 (S 7) • Slide bearings on the crimp tool improve efficiency up to 20%, reduce friction and help keep the tool free of...

Open the catalog to page 8

UNIFLEX changes the names of some products for a better understanding. (The old product names can be found in brackets behind the new product names) SC = Press tool with Cylinder 266_1190_0 Werkzeug_S6.2 Platenwerkzeug 266_1190_0 Werkzeug_S6.2 Platenwerkzeug 266_1190_0 Werkzeug_S6.2 Platenwerkzeug Front view Side view Vorderansicht Vorderansicht Vorderansicht Seitenansicht Seitenansicht Seitenansicht Rückansicht Rückansicht Rückansicht Rear viewt SH = Hollow piston press tool 276_1100_0 Werkzeug_S6.2L Hohlkolbenwerkzeug Front view Side view Rear view No greasing low maintenance Compact...

Open the catalog to page 9

SL 3 Next-generation crimper for low pressure hose assemblies. Two-in-one solution with integrated die sets O5 and O15 for DN 03-16. With the SL 3-16 M, UNIFLEX innovates the existing crimper: two integrated die sets in one tool. No more lost time changing the die. Just change the handle and you are already crimping the other size. No risk of losing dies, no dirty hands, no “time lost”. With the built-in handle, you can easily carry it anywhere. SL 3-32 M and SL 3-75 complete the range with large opening travel up to 3“. Service Crimpers

Open the catalog to page 10

Technical Data Technical Data Opening travel Opening without dies Master dies length (mm) ** With master dies. Dies 150: 6.9 mm and 14.9 mm. 2 sets of dies integrated, no dies set change! (Only for SL3-16M) Service Crimpers

Open the catalog to page 11

SH 2 (S 2) Must workshops and mobile service teams do without the power and reliability of large stationary crimpers? UNIFLEX‘s answer is a definite “no“. Our compact, multi-purpose workshop crimpers prove that the advantages of the legendary slide bearing technology can also be used in light-weight, inexpensive equipment that will fit into almost any vehicle and workshop. The SH 2 series models offer an optimal force-to-weight ratio of 1“ 4 SP at a weight of 29 kg, a large opening stroke up to 22 mm and a maximum pressing range up to 63 mm. Service Crimpers

Open the catalog to page 12

Technical Data Technical Data No grease: 20% less friction Opening without dies Master dies length (mm) Close Crimp Speed (mm/sec) * According to the fitting. ** With master dies. *** 7 bar/98 psi. On S2 M models, an optical signal is given when the crimp measure is reached. The electric and pneumatic variants have an automatic stop function. Telescopic hand-lever available. New standard by S 2 M, S2 M H and S2 M H Ecoline with special pump. (The low pressure delivery volume is around three times higher than the standard.) 32/3 cc instead of 11/3 cc PUM 0.8/3.2-700 bar. The mobile high...

Open the catalog to page 13All Uniflex-Hydraulik GmbH catalogs and technical brochures

-

Image Catalog 2023

28 Pages

-

Test Benches & Cleaning Machines

10 Pages

-

Special Equipment

8 Pages

-

Cutting machines

20 Pages

-

Production Crimper

28 Pages

-

HM660_HM665_HM1200

2 Pages

-

HM450_HM480_HM495

2 Pages

-

HM3H

2 Pages

-

HM325_HM375_HM380

2 Pages

-

HM220_HM225

2 Pages

-

Option and Accessories

10 Pages

-

Catalogue

60 Pages

Archived catalogs

-

2020 Service Crimpers

23 Pages

-

2016 Service Crimpers

15 Pages

-

Product Overview

8 Pages

-

General Catalogue

34 Pages