Website:

Uniflex-Hydraulik GmbH

Website:

Uniflex-Hydraulik GmbH

Catalog excerpts

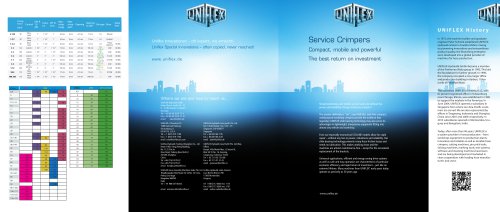

Engineered solutions using quality components Smaller machine increases ergonomics HiLo cylinder - Maximum efficiency causing less heat Noiseless high-quality pump Fixed 6- o‘clock die Workpiece does not move, making it easier to position laterally Increases productivity, driving up profitability Reduces risk for injuries Slide bearing technology No greasing improves cleanliness of machine and prolongs its lifetime Maximum productivity with very low maintenance costs Flaking cannot stick in grease, no risk of prematurely damaging the crimping head End product can be used in sanitary applications without cleaning 20% more capability for crimping stronger or more difficult couplings versus our competition’s equivalent crimpers Consistently accurate crimp result Pressure Force Monitoring PFM – Standard on all machines with C.2 Control Quality-enhancing option for series production. With PFM, the upper and lower pressure limits can be set by adjusting the tolerance values obtained from test pressing. Pressures outside these limits are output as errors. It is possible to let the machine switch off at a fixed upper or lower limit, thereby obtaining a higher process safety. This way you can display and record combinations of incorrect hose and fittings, skipped work stage, such as skiving of the hose or a poorly positioned hose-fitting connection. Achieve integrated quality control without any additional effort. PTS We reserve the right to make technical changes without notice. Options are machine parts that can only be ordered while buying the machine. Due to their narrow, innovative construction, high level of user friendliness, and long service life, the HM 220 and HM 225 set the standard for quality and cost effectiveness. Their unrivaled accessibility makes ergonomic working possible – optionally from both sides – in production and series manufacture. The tried and tested greaseless slide bearing technology reduces maintenance costs, and the strong crimping force of up to 1400 /1600 kN is rated for widths u

Open the catalog to page 1

Technical Data Additional Information HM 220 HM 225 The clear Control C.2 and the optional UTS software provide complete documentation of production data, including the timestamp. The compact, narrow and ergonomic construction makes working on both sides possible. The fixed 6- o’clock die makes safe and low-force positioning of the workpiece possible, which improves cost effectiveness as well as safety. Technical data Speed (mm/sec) Close Crimp Open Standard: Half power twice faster included.

Open the catalog to page 2All Uniflex-Hydraulik GmbH catalogs and technical brochures

-

Image Catalog 2023

28 Pages

-

Test Benches & Cleaning Machines

10 Pages

-

Special Equipment

8 Pages

-

Cutting machines

20 Pages

-

Main catalogue

116 Pages

-

Production Crimper

28 Pages

-

HM660_HM665_HM1200

2 Pages

-

HM450_HM480_HM495

2 Pages

-

HM3H

2 Pages

-

HM325_HM375_HM380

2 Pages

-

Option and Accessories

10 Pages

-

Catalogue

60 Pages

Archived catalogs

-

2020 Service Crimpers

23 Pages

-

2016 Service Crimpers

15 Pages

-

Product Overview

8 Pages

-

General Catalogue

34 Pages