Website:

Uniflex-Hydraulik GmbH

Website:

Uniflex-Hydraulik GmbH

Catalog excerpts

Cutting Machines Clean cutting, safe handling.

Open the catalog to page 1

Cutting Machines • Gleitlagerbleche am Presswerkzeug bieten bis zu 20 % mehr Effizienz, weniger Verschleiß und Werkstücke und Werkzeug bleiben sauber. Universal • Maximale Produktivität, bei extrem geringen Betriebs• kosten types of hoses and fittings.der Maschine. For all und höherer Lebensdauer • Späne setzen sich nicht in Fett und Schmutz fest, dadurch kein Werkzeugverschleiß. Ecoline • Keine Verschmutzung der Schlauchleitung durch Fett • und daher ideal auch for lessLebensmittel- und PharValue driven solution für die frequent use. mabranche. • Gleitlagertechnologie reduziert den...

Open the catalog to page 2

Special features Brake motor Massive motor design Cutting Machines Cutting Blades German Engineering

Open the catalog to page 3

EM 1 | EM 3 UNIFLEX hose cutting machines have been a synonym for the highest precision and robustness for many decades. The solid and compact tools distinguish themselves by their safe and high-quality cutting function. A distinct property is the positioning of the extraordinarily sharp cutting blades close to the powerful motors. This significantly reduces vibration – which is one of the reasons for extreme durability and low maintenance costs. Cutting Machines

Open the catalog to page 4

Technical Data Technical Data Noise level Brake motor Suction connection Cutting blade Suction device * Hose measuring tool UMS 4 * Adapter needed. Tested high-quality cutting blade, secured with a metal sheet. Guide pins ensure straight cuts. Cutting blades Blades TM = plain TM G = slotted TM C = coated High-quality cutting blades: TM C, TM G und TM. TM C Lasts 7 times longer, cuts twice as fast, generates less smoke, less debris in the

Open the catalog to page 5

EM 4 UNIFLEX hose cutting machines have been a synonym for the highest precision and robustness for many decades. The solid and compact tools distinguish themselves by their safe and high-quality cutting function. A distinct property is the positioning of the extraordinarily sharp cutting blades close to the powerful motors. This significantly reduces vibration – which is one of the reasons for extreme durability and low maintenance costs. Cutting Machines

Open the catalog to page 6

Technical Data Technical Data Noise level Brake motor Suction connection Cutting blade Suction device Hose measuring tool UMS 4 Guide pins ensure straight cuts. Blades TM = plain TM G = slotted TM C = coated Cutting blades High-quality cutting blades: TM C, TM G und TM. TM C Lasts 7 times longer, cuts twice as fast, generates less smoke, less debris in the hose and less heat. Reduces the risk of separation of the rubber from the wire.

Open the catalog to page 7

EM 6 | EM 8 UNIFLEX hose cutting machines have been a synonym for the highest precision and robustness for many decades. The solid and compact tools distinguish themselves by their safe and high-quality cutting function. A distinct property is the positioning of the extraordinarily sharp cutting blades close to the powerful motors. This significantly reduces vibration – which is one of the reasons for extreme durability and low maintenance costs. Cutting Machines

Open the catalog to page 8

Technical Data Technical Data Noise level Brake motor Suction connection Cutting blade Accessories Bench Suction device Guide pins ensure straight cuts. Blades TM = plain TM G = slotted TM C = coated Cutting blades High-quality cutting blades: TM C, TM G und TM. TM C Lasts 7 times longer, cuts twice as fast, generates less smoke, less debris in the hose and less heat. Reduces the risk of sepa

Open the catalog to page 9

EM 115 | EM 120 The EM 115 and EM 120 are highly productive cutting machines. These machines are best suited for high volume manufacturing of 2” hoses along with workshop capability for 3” high pressure hoses and 4” industrial hoses. The new UNIFLEX EM 120 is a hose-cutting machine for hydraulic and industrial hoses with outside diameters up to 135 mm. The EM 120 is the first fully electric cutting machine. The hose is pre-bent and locked while the blade is moving up through the hose. Via IPC for Industry 4.0 or IoT, the operator just needs to type in the diameter and the machine sets...

Open the catalog to page 10

Technical Data Technical Data Noise level Brake motor Suction connection Cutting blade Suction device Lateral guide rolls for guiding and positioning of the hose, for a better cutting quality (EM 115) Various bending points selec- Exchangeable guide (two table for straighter cuts and sizes) for optimum positioning of different hose sizes. relief of pinch on the blad. (Only: EM 115) Cutting blades Guide for perfectly centering hoses. (EM 115) High-quality cutting blades: TM C, TM G und TM. TM C Lasts 7 times longer, cuts twice as fast, generates less smoke, less debris in the hose and less...

Open the catalog to page 11

EMI 150 | EMI 200 The new EMI 150 and EMI 200 industrial hose cutting machines from UNIFLEX are available for cutting of up to 6” hoses (EMI 150) and up to 8” hoses (EMI 200). Their compact dimensions and robust design make these cutting machines well suited for small workshops as well as bigger production areas. The machines have wheels, so they can easily be moved to the hose instead of carrying heavy hoses around the workshop. Both devices are equipped with the specially coated TM C cutting blade, which substantially reduces the force required and the wear during cutting. Each machine...

Open the catalog to page 12

Technical Data Technical Data Noise level Brake motor Suction connection Cutting blade Suction device High-quality cutting blades: TM C, TM G und TM. TM C Lasts 7 times longer, cuts twice as fast, generates less smoke, less debris in the hose and less heat. Reduces the risk of separation of the rubber from the wire.

Open the catalog to page 13

UPG 10 Cutting thick industrial hoses like a hot knife through butter is not very easy, even if the hoses are not metal-reinforced. Therefore, UNIFLEX has developed a special cutting machine for extremely fast, simple and clean cuts of hoses up to a diameter of 2” with a pneumatically driven and razor-sharp guillotine. Safety and protection at the workplace and ergonomics are a matter of course for this UNIFLEX machine – as is the 2-year manufacturer’s warranty. Guillotine for industrial hoses without steel wire Noise level 2 Guide Pins for smaller size Cutting Machines 334.034.4: \-shaped...

Open the catalog to page 14All Uniflex-Hydraulik GmbH catalogs and technical brochures

-

Image Catalog 2023

28 Pages

-

Test Benches & Cleaning Machines

10 Pages

-

Special Equipment

8 Pages

-

Main catalogue

116 Pages

-

Production Crimper

28 Pages

-

HM660_HM665_HM1200

2 Pages

-

HM450_HM480_HM495

2 Pages

-

HM3H

2 Pages

-

HM325_HM375_HM380

2 Pages

-

HM220_HM225

2 Pages

-

Option and Accessories

10 Pages

-

Catalogue

60 Pages

Archived catalogs

-

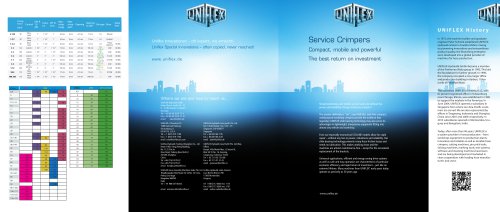

2020 Service Crimpers

23 Pages

-

2016 Service Crimpers

15 Pages

-

Product Overview

8 Pages

-

General Catalogue

34 Pages