Catalog excerpts

- Safety Valve & Control Valve Division

Open the catalog to page 1

PRESSURE RELIEF Valve Type-SV-200-LP/SV-200- This product range is mainly used forThermal Relief application but thanks to the certified coefficient of discharge for gas and liquid it can be used also for pressure relieving application. Types SV-200 covers the application where users have preference for screwed connection. These valves are available with inlet sizes from V2" to 1" and Liquid in various material combinations. Type SV-300 has flanged end connections with an integral cast - Safety Valve & Control Valve Division

Open the catalog to page 2

MAIN FEATURES Screwed and Flanged, Spring Loaded, Direct Acting, Full Nozzle pressure relief valves. Media : Gas, Steam and Liquid. Overpressure : Gas, Steam and Liquid 10%. Set pressure range : From 0.8 bar to 400 bar (for Gas), up to Materials : Carbon Steel, Alloy Steel, Hastelloy, Monel and other materials upon request. Options : Bellows, Flushing, Nozzle, Lifting lever, Testgag, Resilient or Hardened Seat. Sizes/Pressure Classes Size inlet & outlet: from NPS 1/2 to NPS 1 & from NPS 1 to Design Codes & Product Standards Homologations & Approvals CE marking (97/23/CE PED and 94/9/CE...

Open the catalog to page 3

COLD DIFFERENTIAL TEST PRESSURE TOLERANCE The tolerances on the cold differential test pressure are the over 2 Ibar ±1%or 0,7 bar whichever is greater MINIMUM COLD DIFFERENTIAL TEST PRESSURE (SPRING SETTING) The minimum setting pressure are the following:

Open the catalog to page 4

BELLOWS TYPE SAFETY VALVES Series SV-200-HP; SV-300 valves with Orifice "f" may be supplied with balancing and separation bellows Valves of this type are used to: a) Prevent set pressure variations in case of variable back b) Separate the disc guide and all components inside the bonnet from the process fluid when the latter is corrosive, viscous or likely to leave deposits, incrustations The bellows are designed to afford the greatest possible flexibility, greatest mechanical strength and the best possible balancing. The selection UKL-AST of safety relief valves is simplified by an...

Open the catalog to page 5

- Safety Valve & Control Valve Division

Open the catalog to page 6

I l€i 9 UNI KLINGER LIMITED 0ther dimensi0ns on re(^uest ^^^^ - Safety Valve & Control Valve Division

Open the catalog to page 7

On request: (1) For liquids OUT. 1/2"-3/4"-1" A For liquids max set pressure 1500bar Other dimensions on request © For liquids max set pressure 800 bar - Safety Valve & Control Valve Division

Open the catalog to page 8

On request: (1) For liquids OUT. 3/4" ANS1150/300 (2) For liquids OUT. 1" ANS1150/300 Other dimensions on request - Safety Valve & Control Valve Division

Open the catalog to page 9

Soft seated disc (viton; Kalrez) jacket connection jacket connection Cap with packed or plain lever Closed Bonnet Valve with Extension jacket connection . jacket connection For All Orifiees Jacket Connction Will Be 1/3" NPT-F jacket Limiting Pressure: 10 Bar Limiting - Safety Valve & Control Valve Division

Open the catalog to page 10

SERIES VALVES FEMALE SCREWED MALE SCREWED WELDING CONNECTION LIFTING LEVER - Safety Valve & Control Valve Division The dimensions and weights are approximate. UKL-AST will not assume any liability for discrepancies between actual dimensions and weights and those shown in this

Open the catalog to page 11

FLANGED CONNECTIONS LIFTING LEVER - Safety Valve & Control Valve Division

Open the catalog to page 12

STANDARD MATERIALS Remark: On request the valves can be supplied partially or completely in AISI316 - Monel - Hastelloy - Aluminum etc. DEFINITIONS (abstract from EN ISO 4126-1) The actual travel of the valve disc away from the closed position. Flow area The minimum cross-sectional flow area (but not the curtain area) between inlet and seat which is used to calculate the theoretical flow capacity, with no deduction for any obstruction. The value of actual flowing capacity (from tests) divided by the theoretical flowing capacity (from calculation). Built-up backpressure The pressure existing...

Open the catalog to page 13

QUALIFICAZIONE (j^) VALVOLE Dl SICUREZZA QUALIFICATION OF (^) SAFETY-RELIEF VALVES ITALIAN STATE ORGANIZATION ANCC CDNTROLLO DELLA COMBUSTIONE ENTE 01 OIRITTO PUBBLICO - LEQGE 18 GIUONO 1B27 H. 1132 SEDE CENTRALS Direzione Centrale Tecnica e p.c, Al Direttore della Sezione A1JCC di OGGETTO: Qualificazione valvole di sicurezza AST per fluidi vari - Kodelli SI.TFK Visti i risultati delle prove condotte presso I'Istituto di I-acchine le valvole di sicurezza di costruzioni AST con il coefficiente di efflusso: per covrapressione noli iiiferiore al W/o della pressione di taratura e contro-...

Open the catalog to page 14

Reseating pressure (of a safety valve) The value of the inlet static pressure at which the disc re-establishes contact with the seat or at which the lift becomes zero. Relieving pressure The pressure used for the sizing of a safety valve which is s set The predetermined pressure at which a safety valve under operating conditions commences to open. It is the gauge pressure measured at the valve inlet at which the pressure forces tending to open the valve for the specific service conditions are in equilibrium with the forces retaining the valve disc on its seat. Blowdown (of a safety valve)...

Open the catalog to page 15All Uni Klinger Limited catalogs and technical brochures

-

Compressed Asbestos Fiber

2 Pages

-

Expanded PTFE Sheets

2 Pages

-

Spiral Wound Gasket

4 Pages

-

Metal jacketted Gasket

2 Pages

-

Kammprofile Gasket

2 Pages

-

Non-Asbestos Gland Packing

4 Pages

-

SMU-7000 Safety Relief Valve

34 Pages

-

Compressed gasket materials

2 Pages

-

Non Asbestos Gland Packings

4 Pages

-

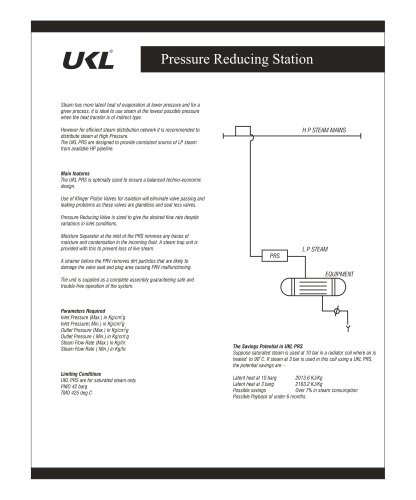

Pressure Reducing Station

2 Pages

-

UCT-10 CLEAN STEAM TRAP

1 Pages

-

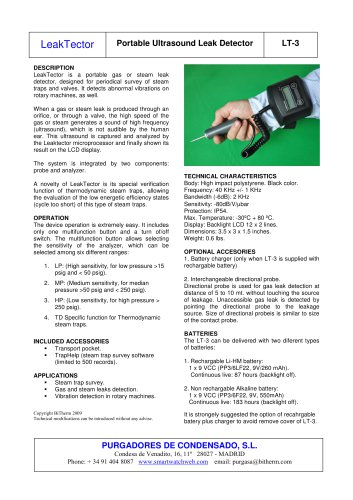

LeakTector

1 Pages

-

ITVS

4 Pages

-

SV-100 Safety Relief Valve

34 Pages

-

AST CV-8000 Control Valve

31 Pages

-

High Pressure Valve UHPV

6 Pages

-

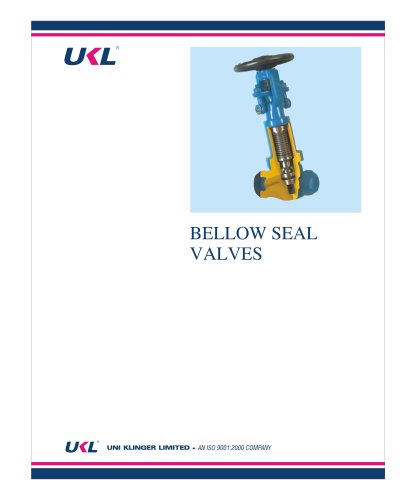

Bellow Seal Valves

20 Pages

-

Piston Valves

12 Pages