Catalog excerpts

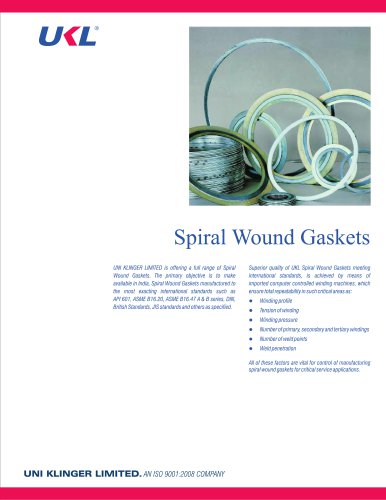

Spiral Wound Gaskets UNI KLINGER LIMITED is offering a full range of Spiral Wound Gaskets. The primary objective is to make available in India, Spiral Wound Gaskets manufactured to the most exacting international standards such as API 601, ASMEB16.20, ASMEB16.47A & B series, DIN, British Standards, JIS standards and others as specified. Superior quality of UKL Spiral Wound Gaskets meeting international standards, is achieved by means of imported computer controlled winding machines, which ensure total repeatability in such critical areas as: • Winding profile • Winding pressure • Number of primary, secondary and tertiary windings • Number of weld points • Weld penetration All of these factors are vital for control of manufacturing spiral wound gaskets for critical service applications.

Open the catalog to page 1

The design principle ofUKL Spiral Wound Gaskets: The basic sealing component of every Spiral Wound Gasket is the wound element. The unique profiled metal strip is spirally wound to integrate with the specified sealing element material. To improve the mechanical strength and other sealing characteristics and to comply with international standard, some layers at the beginning and at the end are wound without soft material and spot-welded over the total circumference. Consistency of winding tension combined with the profile of the winding, provide for a superior sealing performance. This...

Open the catalog to page 2

• Wide choice of materials for metal strip and filler. (Low/ high density). • Suitable for high pressures and temperatures application. • Recommended for flanges with tongue and groove. • Solid metal outer ring used as a centering device and compression stop. • Used on raised face and flat face flanges. • Consists of solid metal inner ring. • Suitable for high pressures and temperatures. • Recommended for male and female flanges. • Consists of solid metal outer and inner rings. • Suitable for high pressures and temperatures applications. • Used on raised face or flat face flanges. •...

Open the catalog to page 3

Technical SpecificationGasket Size Range:_ Standard 15 NB to 1500 NB Standard Filler Materials Asbestos PTFE Flexible Graphite Metal Winding Standard Material Stainless Steel 304 / 316L/ 321 / 410 / 347 Monel 400_ Titanium, Hastelloy, Incoloy 800 / 825 Outer Ring and Inner Ring Standard Materials Cabon Steel (Zinc Plated with Chrome Passivation / Painted / Powder coated) Stainless Steel 304 1 410 / 316L Monel, Nickel, Incoloy Titanium, Inconel 600 / 625 Standard Gasket thickness Nominal Compressed Outer / Inner ring thickness thickness thickness Also available:...

Open the catalog to page 4All Uni Klinger Limited catalogs and technical brochures

-

Compressed Asbestos Fiber

2 Pages

-

Expanded PTFE Sheets

2 Pages

-

Metal jacketted Gasket

2 Pages

-

Kammprofile Gasket

2 Pages

-

Non-Asbestos Gland Packing

4 Pages

-

SMU-7000 Safety Relief Valve

34 Pages

-

Compressed gasket materials

2 Pages

-

Non Asbestos Gland Packings

4 Pages

-

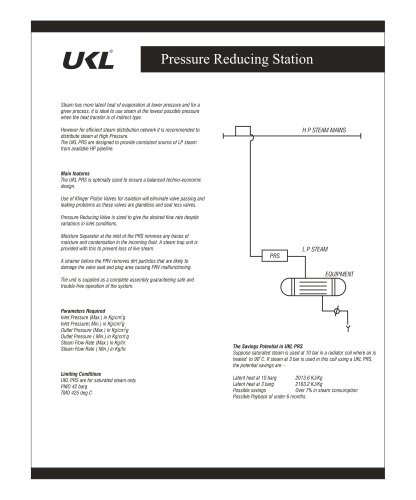

Pressure Reducing Station

2 Pages

-

UCT-10 CLEAN STEAM TRAP

1 Pages

-

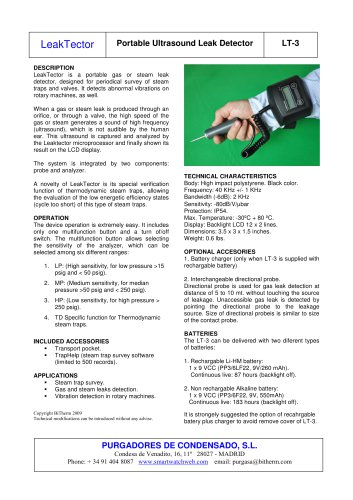

LeakTector

1 Pages

-

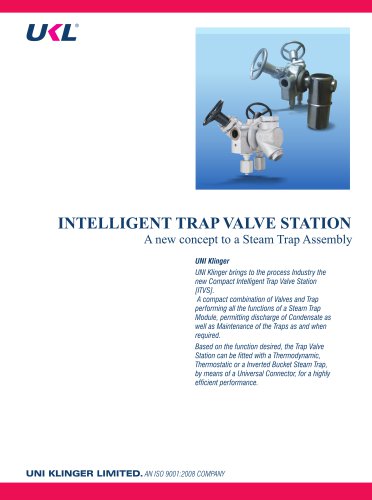

ITVS

4 Pages

-

SV-100 Safety Relief Valve

34 Pages

-

SV 200 & 300 Safety Relief Valve

15 Pages

-

AST CV-8000 Control Valve

31 Pages

-

High Pressure Valve UHPV

6 Pages

-

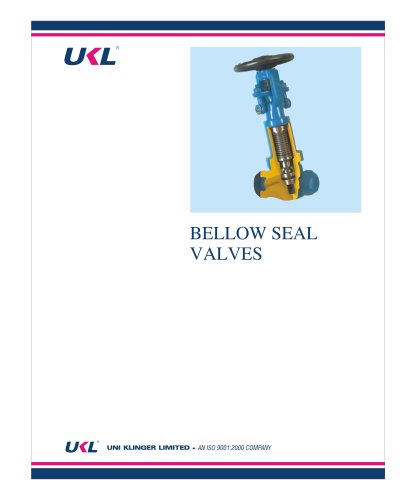

Bellow Seal Valves

20 Pages

-

Piston Valves

12 Pages