Catalog excerpts

SAFETY VALVES SERIESSMU-7000 UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 1

PRESSURE-RELIEF VALVES SMU-7000 SERIES SMU-7000 This range of spring loaded conventional Pressure Relief Valves is for Installation of any SECTION I/III application and are available from pressure range of 0.3 Bar to 414 Bar and for pressure ratings up to 2500#. Sizes from 1” D 2” to 8” T 12” in different material of construction depending on the application. UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 2

Media Orifices Set pressure range Temperature range Overpressure Blowdown Materials Main Features Flanged, Spring loaded, Direct acting, Full nozzle pressure relief valves. : Gas, Steam and Liquid. : From “D” to "T" acc. To API 526; Intermediate orifices (K2, P2, Q2, R2) and orifices up to 1520.5 cm2 available. From 0.3 bar to 414 bar. From -267o Cto715oC. Gas and Steam 3% or 10%, Liquid 10%. Gas and Steam 5% to 7%. Carbon Steel, Alloy Steel, Hastelloy, Monel and other materials upon request. Bellows, Flushing nozzle, Lifting lever, Test gag, Finned bonnet, Limit switch, Resilient or...

Open the catalog to page 3

Relieving Temperature INTRODUCTORY NOTES COLD DIFFERENTIALTEST PRESSURE TOLERANCE The tolerances on the cold differential test pressure are the following: Up to 3,7 bar ±4% or ±0,04 bar whichever is greater over 21 bar ±1% orO, 7 barwhichever is greater MINIMUM COLD DIFFERENTIAL TEST PRESSURE (SPRING SETTING) The minimum cold differential test pressure is shown in the following table. For conventional valves with special construction, the minimum cold differential test pressure can be reduced to 0,4 bar. SEATTIGHTNESS (Nozzle - Disc) UKL AST uses more severe limits than suggested in...

Open the catalog to page 4

Tungsten steel spring and Materials to table,page 10 Completely in AISI304 Materials to table, page 10 Materials to table, page 10 Materials to table, pag. 10 Bellows Plain lever (no stuffing box) Packed lever (stuffing box) Testgag Heating jacket O-ring (soft seated disc) Finned bonnet extension (high temperature duty) Valve seat injection nozzles Special trim for liquids. Example: SMU-7000-W/BLT - Valve construction of materials as per list, page 10 - For utilization in the temperature range 232,5 - 426°C - Tungsten steel valve spring - balancing bellows packed lever and test gag...

Open the catalog to page 5

Open Bonnet Valve Temperature max 35(fC With Carbon Steel Spring Closed Bonnet Valve with Extension To use temperature range from 426 °C to 538 °C UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 6

Soft, seated disc (viton; teflon; kalrez) for low pressures (max 19 bar) and temperature (-29°C + 20(fC) UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 7

U<L Jacketed Body Valves Series SMU-7000 BODY VALVE HEATING JACKET (Jacket limiting pressure: 10kg/cm2 limiting temperature 185°C.)

Open the catalog to page 8

SERIES SMU-7000 VALVES Nozzle-disc seats manufactured by UKLAST are of the metal to metal type. They can be supplied hardened (with stellite or made in 174PH) or resilient (with o-ring). The most frequent cases in which these constructions are requested are: 1) hardened when the media is dirty, may crystallize or contain solids 2) hardened for medium and high pressure depending on the temperature, see following diagram 3) resilient when requested by client UKL AST will suggest the best solution for each operating condition. UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 9

On request the valves can be supplied partially or completely in Aluminium UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 10

PRESSURE AND TEMPERATURE LIMITS (standard construction) orif cnf sq.in (a) Non API526 center to face dimension (b) Class 600 not included in API526 UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 11

ORIF cnf sq.in U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 12

SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526)

Open the catalog to page 13

ORIFICE 1,389 cm2 0,215 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526)

Open the catalog to page 14

ORIFICE 2,164 cm* 0,335 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 15

SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 16

ORIFICE 5,515 cm* 0,854 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 17

ORIFICE 9,079 cm2 1,407 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 18

SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 19

K. ORIFICE 16,619 cm1 2,575 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 20

ORIFICE 20,109 cm2 3,116 iif SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526)

Open the catalog to page 21

ORIFICE 25,339 cm2 3927 in* SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 22

ORIFICE 30,581 cm2 4,740 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 23

ORIFICE 45,007 cm2 6,976 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526)

Open the catalog to page 24

ORIFICE 63,617 cm2 9,861 in2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526) U<L UNI KLINGER LIMITED - Safety Valve & Control Valve Division

Open the catalog to page 25

ORIFICE 77,913 cm2 12,076 In2 SELECTION CHART PRESSURE-TEMPERATURE LIMITS (ACCORDING TO ANSI B16.34 AND API 526)

Open the catalog to page 26All Uni Klinger Limited catalogs and technical brochures

-

Compressed Asbestos Fiber

2 Pages

-

Expanded PTFE Sheets

2 Pages

-

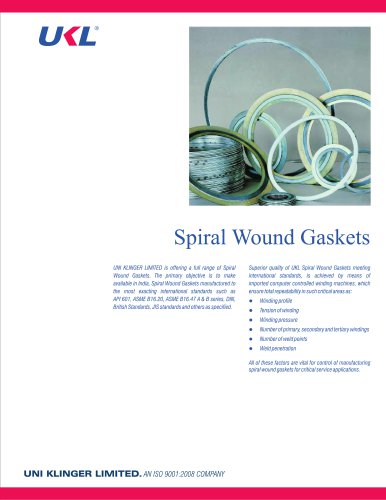

Spiral Wound Gasket

4 Pages

-

Metal jacketted Gasket

2 Pages

-

Kammprofile Gasket

2 Pages

-

Non-Asbestos Gland Packing

4 Pages

-

Compressed gasket materials

2 Pages

-

Non Asbestos Gland Packings

4 Pages

-

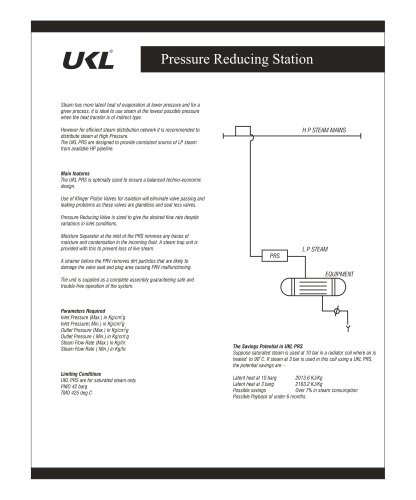

Pressure Reducing Station

2 Pages

-

UCT-10 CLEAN STEAM TRAP

1 Pages

-

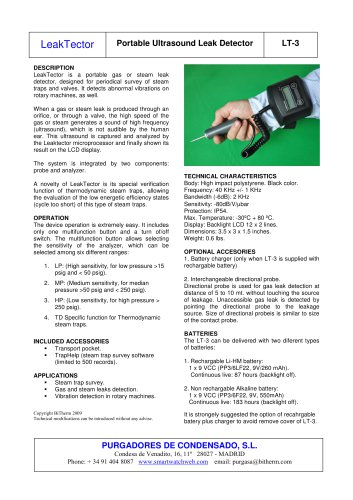

LeakTector

1 Pages

-

ITVS

4 Pages

-

SV-100 Safety Relief Valve

34 Pages

-

SV 200 & 300 Safety Relief Valve

15 Pages

-

AST CV-8000 Control Valve

31 Pages

-

High Pressure Valve UHPV

6 Pages

-

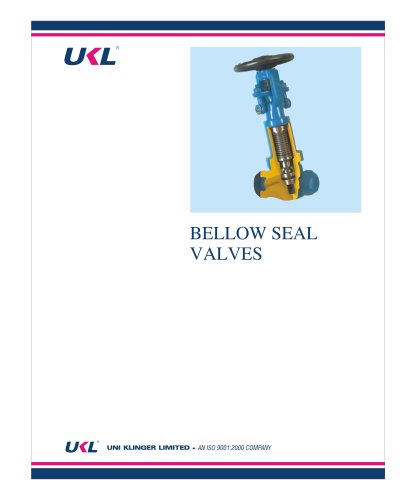

Bellow Seal Valves

20 Pages

-

Piston Valves

12 Pages